MOJ

eISSN: 2572-8520

Research Article Volume 4 Issue 3

Department of Mechanical Engineering, Federal University of Ouro Preto, Brazil

Correspondence: Lidianne de Paula Pinto, Department of Mechanical Engineering, Federal University of Ouro Preto Bauxita, Morro do Cruzeiro, Bauxita, Minas Gerais, 3540 0000, Brazil

Received: May 15, 2018 | Published: June 21, 2018

Citation: Quintão PAF, Pinto LP, Mendes BM, et al. Impact test: comparative analysis between welds make by MIG and RSW process. MOJ Civil Eng. 2018;4(3):156-159. DOI: 10.15406/mojce.2018.04.00114

The electrical resistance spot welding process (RSW) by electrical resistance has been used in the automotive industry for several decades and is currently the most applied process for joining the various types of assemblies that make up the vehicle body. In vehicle maintenance, the welding process with inert metal gas (MIG) is generally used. The present work presents a comparative study between steel specimens welded through the process of spot welding by electrical resistance and welded through the process of welding with inert metal gas, as well as its capacities to absorb energy when subjected to an impact. The analysis of the energy absorbed from the specimens made by RSW welding and the MIG process were performed using the student t–test. Through the results, it is possible to observe that the specimens welded through the RSW process have a greater energy absorption capacity.

Keywords: impact test, electrical resistance spot welding, MIG welding

Aiming at the safety of users, Automotive Engineering studies the Active and Passive Safety of vehicles. Two major challenges are constant concerns of engineering that work in vehicle safety: to develop and make feasible new technological solutions that avoid or minimize the effects of a traffic accident. In two distinct and complementary approaches, while active safety seeks solutions to prevent the accident from occurring, passive safety seeks solutions to minimize the consequences of the accident to occupants of the vehicle.1,2 The process of spot welding by electrical resistance has been used in the automotive industry for several decades, and is currently the most applied process in joining the various types of assemblies that make up the vehicle body. Spot welding is a process in which the surfaces are joined by means of one or more points on which heat and pressure are applied. The heat is generated by the resistance to an electric current passing through the parts held in contact for a short period of time. When the intensity of current ceases, the pressure is maintained as the metal solidifies. The process uses low voltage, high current intensity and pressure.3,4 The electrodes play a fundamental role in the spot welding process, because it is through them that the current flows, which allows the generation of heat, as well as exerting the necessary pressure on the parts and cooling the welding region.5 The electrodes are manufactured with different geometries, each of which has its purpose and application. The electrode geometries define the current density that will pass through the parts to be welded.6 The current is the parameter that most influences the heat generation during spot welding, and the variations in its magnitude significantly change the properties of the weld.5 Due to the competitiveness of the automotive sector, vehicle manufacturers have undergone a major restructuring, mainly in the manufacturing area, where great flexibility is required to supply the demand. These facts show the importance of the study of this welding process, due to its efficiency, speed and ease in automation. In vehicle maintenance the commonly used welding process is an arc process involving the use of inert gases. The arc welding process involving the use of gases can be divided into two types: with active gases (MAG) and inert gases (MIG). In this process the bonding of materials occurs through heating with an electric arc established between part and electrode, where the gaseous atmosphere allows the protection of the puddle of fusion and stabilization of the gas.7,8 The quality of the welds is affected by the heat–affected zone (HAZ), the region of the base metal adjacent to the melt puddle. The diffusion of heat to the base metal is strongly influenced by the melt puddle temperature and the welding speed. Welding with high power and high speed reduces the thermal gradient. At one point in the HAZ just beyond the edge of the melting puddle the temperature increases rapidly and is close to that of the melting puddle and decreases rapidly producing a quenching effect. In steels this region becomes austentic during heating and may contain the hard constituent known as marten site when it cools, brittle and hard microstructure. A little further, where the temperature was not so high, entering the range above the transformation temperature but not reaching the austenitic region, the grain size is smaller (grain refining region). Further still, there is no change in grain size, but heat is sufficient to reduce the hardness of that region (inter critical region).8,9 The purpose of this work is to perform a comparative study of welded specimens by means of the electrical resistance spot welding process and trough the MIG welding process, as well as their ability to absorb energy when subjected to an impact.

Specimens and welding parameters

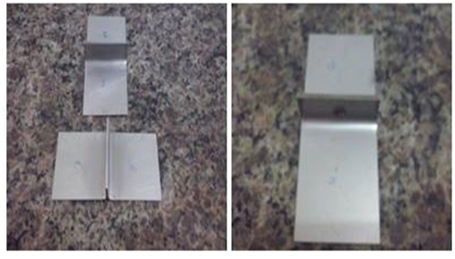

The carbon steel SAE 1020 specimens were fabricated 20 mm flap height and 50 mm width using plates of 1 mm thickness. In Figure 1 it is possible to observe the dimensions of the manufactured specimens. The electric arc welding process with gaseous protection atmosphere was used in this study to join the plates, using an inert gas to protect the fusion well. This process has been characterized in the market as MIG (metal inert gas). To analyze this process under the impact test, six specimens (Figure 1) were manufactured with a 6 mm hole diameter and 6 specimens with a 8 mm hole diameter to fill the weld, thus joining the plates. The parameters used were voltage 22 V, current 110 A, welding speed 240 cm/min, gas flow 12 L/min, arc time 20 s and 8 mm diameter wire. The spot welding process was carried out in this study using an electric resistance point welding machine, which has a suspended welding caliper with pneumatic cylinder from the manufacturer FASE model X/4 – 200. The electrodes used comply with Class 20 of RWMA standard. In this process, the diameter of the solder lens is a function of the welding current of 6 kA and 7 kA. The current time in this process is 20 cycles and the electrode strength is 1.8 kN. These parameters produced points with a diameter of 4 mm (approximately). Twelve specimens were manufactured through that process with the same dimensions shown in Figure 1 without the manufacture of a hole for joining the plates, six specimens at 6 kA and six specimens at 7 kA. In Figure 2A it is possible to observe a specimen manufactured by the RSW welding process and in Figure 2B a specimen manufactured by the MIG welding process.

Equipment and experimental testing

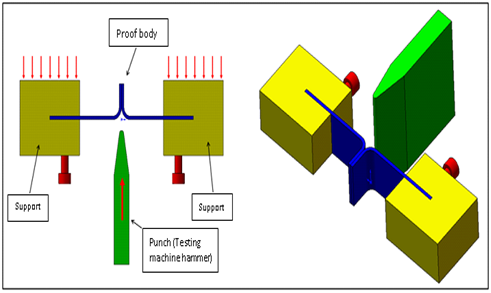

After the test specimens were manufactured, the experimental tests were performed on an AMETEK type impact test machine (Figure 3), with a maximum capacity of 330 Joules. The hammer used is type 1, has 30 kg and the cleaver ASTM. The machine shown in Figure 3 provided the energy absorbed in kg, for a better interpretation of the results the unit transformation was made to Joule. The assay temperature was at room temperature. The fixation of the specimen on the test machine can be seen in Figure 4. The fastening was carried out on a support at the base of the machine by means of screws (Figure 4), allowing the impact hammer wedge to reach precisely the welded joint as shown in Figure 5. The impact tests were first performed on the specimens manufactured trough MIG weld of 6 mm and 8 mm hole diameters. Subsequently, the impact tests in the welded specimens by means RSW process at 6 kA and 7 kA were carried out. Finally, the energy absorbed from the specimens welded by the two types of weld was compared by means student t–test.

In Figure 6 it can be seen the energy absorbed by the specimens with hole diameters of 6 mm and 8 mm welded by MIG during the impact test. It is observed from Figure 6 that all 8 mm hole diameter specimens absorbed greater energy than the 6 mm hole diameter specimens. On average, 6 mm hole diameter specimens absorbed 98.4 Joules, while 8 mm hole diameter specimens absorbed an average of 117.1 Joules. The Figure 7 shows the energy absorbed by the spot welded specimens under 6 kA and 7 kA current. It can be seen from Figure 7 that the specimen 1 (blue line) for welding at 6 kA and specimen 3 (orange line) for welding at 7 kA showed relatively higher energy absorption when compared to the others under the impact test. This was due to the electrode profile that was not sharp when the respective samples were welded. Thus, it is verified that the energy absorbed when the specimens are welded at 6 kA and 7 kA are similar, which means that these parameters did not influence the welding significantly. Therefore, only the specimens welded at 6 kA were considered to evaluate the energy absorbed in relation to the specimens welded trough MIG with hole diameter of 6 mm. From Figure 8 it is possible to observe the absorbed energy of welded specimens by means of electrical resistance spot welding (6 kA) and the MIG welding process (6 mm). Table 1 shows the statistical analysis using Student t–test as an analytical method, with a significance level of 0.05. The results showed that the mean energy absorbed between test specimens produced by the MIG welding process and the electrical resistance spot welding did not show significant differences. However, the average energy absorbed from specimens produced with the MIG process showed significant differences between specimens with 6 and 8 mm fill holes.

MIG |

RSW |

|||||

|---|---|---|---|---|---|---|

Specimen |

6mm |

8mm |

6kA |

7kA |

||

1 |

100 |

120 |

225 |

100 |

||

2 |

100 |

120 |

110 |

140 |

||

3 |

90 |

100 |

105 |

210 |

||

4 |

100 |

120 |

100 |

108 |

||

5 |

95 |

100 |

130 |

105 |

||

6 |

108 |

140 |

125 |

105 |

||

Average |

98,8 |

116,7 |

132,5 |

128 |

||

Variance |

36,2 |

226,7 |

2187,5 |

1822,0 |

||

Student t–distribution: two specimen assuming different variances |

||||||

6mm – 8mm |

6mm – 6kA |

6mm – 7kA |

8mm – 6kA |

8mm – 7kA |

6kA – 7kA |

|

t calculate |

–2,69 |

–1,75 |

–1,66 |

–0,79 |

–0,61 |

0,17 |

t critical |

2,36 |

2,57 |

2,57 |

2,45 |

2,45 |

2,23 |

Rejects |

Accepts |

Accepts H0 |

Accepts |

Accepts |

Accepts |

|

|

H0 |

H0 |

|

H0 |

H0 |

H0 |

Table 1 Statistical analysis

It was analyzed the energy absorption of specimens welded trough the electrical resistance spot welding and welded by mean the MIG subjected to impact test.. It is verified that when changing the current supply of RSW process from 6 kA to 7 kA, there was no significant change in the energy absorbed between the specimens manufactured. However, in the MIG welding when changing the fill hole diameter of the specimens from 6 mm to 8 mm, there was a significant alteration of absorbed energy. The specimens welded by electrical resistance spot welding and welded by the MIG process absorbed close energy values, although the diameter of the weld point produced by the RSW process was smaller than that produced by the MIG process (diameter of 4 mm). Therefore, the specimens welded to the RSW point absorb more energy than the specimens welded with the similar weld point produced by the MIG process.

None.

The author declares there is no conflict of interest.

©2018 Quintão, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.