Journal of

eISSN: 2373-437X

Research Article Volume 2 Issue 7

Biosciences and biotechnology, Mekelle University, Ethiopia

Correspondence: Kiros Haddish, Lecturer, Biosciences and biotechnology, Mekelle institute of technology, Mekelle University, Ethiopia, Tel 25100910905704

Received: August 02, 2015 | Published: December 19, 2015

Citation: Haddish K (2015) Production of Single Cell Protein from Fruit of Beles (Opuntia Ficus-Indica L.) Peels Using Saccharomyces cerevisiae. J Microbiol Exp 2(7): 00073. DOI: 10.15406/jmen.2015.02.00073

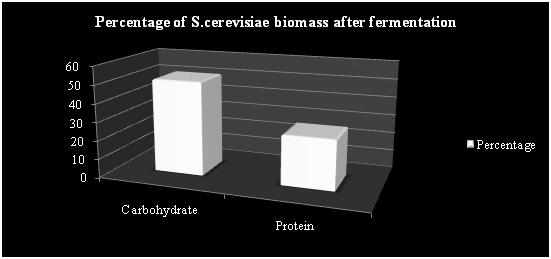

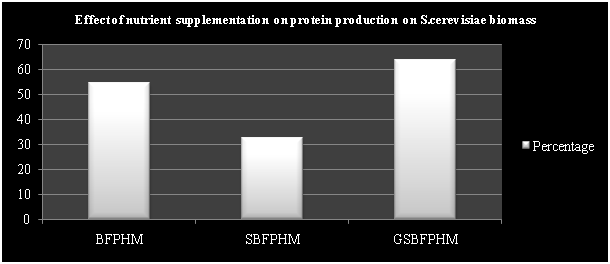

The bioconversion of different wastes into certain valuable products like single cell protein (SCP) has simultaneous ability to solve the worldwide food protein deficiency by obtaining an economical product for food and feed and alleviating environmental pollutants up to significant extent by using these wastes as substrates for the production of the high nutritious product. Therefore, the present study aimed to assess the feasibility of using Beles fruit peels (the remained wastes of cactus pear fruit which is common in northern Ethiopia, Tigray region) for Saccharomyces cerevisiae production and to evaluate protein quality of produced single cell protein (SCP) biomass. In this work, Beles fruit peels were evaluated for the production of single cell protein using Saccharomyces cerevisiae by submerged fermentation. Results showed that Beles fruit peels generate 51.1% and 27% crude carbohydrate and crude protein, respectively per 100gm of substrate used. In addition, Percentage of protein in single cell protein was lower (32.5%) when Saccharomyces cerevisiae was grown on supplemented Beles fruit peels hydrolysate medium that contained inorganic nitrogen sources but devoid of glucose. Addition of glucose to the supplemented Beles fruit peels hydrolysate medium enhanced the protein content (63.5%) within the yeast cell. Thus, the present research work helps in SCP production from inexpensive and cheap agro-waste materials, even if single cell protein production by yeast depends on the growth substrates and/or media composition.

Keywords: single cell protein, Saccharomyces cerevisiae, Beles fruit peels

The frequent population growth in developing countries has led to an increase in animal and human food supply. The mounting world demand for protein rich food led to look for the formulation of alternative protein sources which are particularly Single Cell Proteins (SCP). SCP is one of the most important steps for this goal and is an alternative and an innovative way to successfully solve the global food problem.1 SCP refers to cells or proteins derived from microorganisms such as bacteria, fungi, mold, algae and yeasts among which yeasts are probably the most widely accepted and used microorganism for single cell protein.2 SCP production technologies arose as a promising way to solve the problem of worldwide protein shortage. They evolved as bioconversion processes which turned low value by-products, often wastes, into products with added nutritional and market value. Intensive research into fermentation science and technology for biomass production, as well as feeding, has resulted in a profound body of knowledge, the benefits of which now span far beyond the field of SCP production.

Following its introduction in the mid-nineteenth century, cactus pear (Beles) became one of the more popular plants in northern Ethiopia, particularly in the Tigray region. For more than 50 years, the cactus pear fruit has been considered an important forage crop and a major source of income and food for peasant growers in the period from June to August. Cactus pear is an important part of the cultural heritage and a food resource for people in the Tigray region. The cactus pear’s important ecological role in the region is exemplified such as combating desertification, soil remediation, as a refuge and a food source for wild fauna, as well as providing fruit and cladodes for people, forage for cattle and biomass for energy.3 Therefore the present study was carried out to assess the potential of Beles’ fruit peels for cost effective yeast biomass production. In this work, Beles’ fruit peels were introduced as a potential substrate for fermentation to produce bioprotein which can be used in food as such or as animal feed.

Collection of Beles’ fruit peels and microbial culture

Beles fruit peels were collected from the local market of Mekelle district, Ethiopia in sterile bottles. By gently washing these peels with distilled water, dust particles were removed. The peels were dried and crushed into fine powder with an electric grinder.

The microorganism used to ferment Beles’ fruit peels was Saccharomyces cerevisiae obtained from the college of veterinary medicine, Mekelle University, Ethiopia. The cultures were maintained on the slant of Potato Dextrose Agar medium (Potato infusion 200g, Dextrose 20g, Agar 20g, Distilled water 1000ml) and stored at 4°C until further investigation.

Sample preparation for S. cerevisiae

Beles fruit peels (in the form of powder) were used as substrate for production of SCP. The peels were treated with 50ml of 10% (w/v) HCl and kept in a water bath at 75°C for one hour to obtain monosaccharides as S. cerevisiae lacks the enzymes responsible to hydrolyze the polysaccharides into simpler glucose units. The mixture/solution was placed in a water bath at 100°C for one hour. After being cooled, it was filtered through Whatman filter paper. The filtrates were diluted with sterile distilled water at varying concentrations and autoclaved at 121°C for 15 mints. The sterile solution/broth thus prepared was used as carbon and nitrogen source for biomass production and the protocol was taken from,4-14 with little modifications.

Production and harvesting of SCP

Submerged fermentations were carried out in Erlenmyer flasks with three trial media. The first trial was designated as supplemented Beles’ fruit peels hydrolysate medium (SBFPHM) which had the following compositions (NH4)2SO4 (2gm), KH2PO4 (1gm), MgSO4.7H2O (0.5gm), NaCl (0.1gm), CaCl2 (0.1gm) (pH-5.5) made up to 1L BPH. The second medium was designated as glucose supplemented Beles’ fruit peels hydrolysate medium (GSBFPHM) had all the compositions of BFPH and glucose (2gm/l). The third had Beles’ fruit peels hydrolysate medium (BFPHM) only. In all the media, initial pH was adjusted to 5.5 using 1N H2SO4 and/or 1N NaOH. Each medium (100ml) was transferred into a 250ml Erlenmeyer flask and sterilized at 121°C for 15 mints. Inoculums of 2ml from suspension of Saccaharomyces cerevisiae was aseptically transferred into each medium. Fermentation was carried out at 28°C under static condition followed by determination of biomass and other parameters after 6-day intervals as discussed in.15 After fermentation biomass was separated from culture broth by vacuum filtration and washed with sterile water. Before taking the weight of the biomass, it was transferred into an aluminum disk and was oven dried at 105°C for one hr, followed by cooling in desiccators to balance the temperature and weight with little modifications of this procedure.10

Chemical analysis

Beles fruit peels samples were analyzed at dry weight basis for proximate crude protein, crude fat, crude fiber, ash, moisture and crude CHO content by following their respective procedures.11

Analysis of S. cerevisiae biomass

The biomass of S. cerevisiae on each batch was analyzed for its ash, crude fiber, crude fat and crude protein contents using the procedure mentioned in AOAC methods.15

Photograph 1, Figure 1, Figure 2, Figure 3

Photograph of Beles’ fruit peels used in the production of SCPs. (Source: I took the photo from my parent’s of the Beles garden in 07, 29 may 2015 at 3:20 AM, Ethiopia).

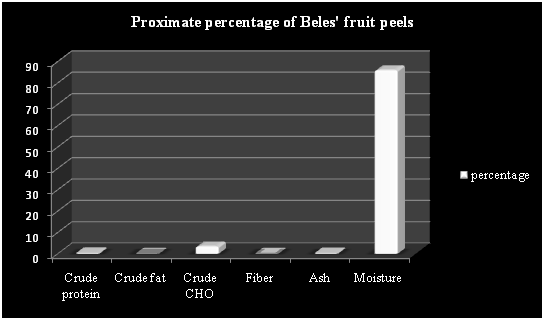

Figure 1 Proximate composition of Beles’ fruit peels.The above figure indicates that the major proximate composition of Beles’ fruit peels and moisture content has found to be the highest percentage.

Figure 2 It represents the proximate composition of yeast biomass produced after fermentation, which revealed that the amount of crude carbohydrate produced from Beles’ fruit peels by Saccahaoromyces cerevisiae was 51.1% and the crude protein was 27%.

Figure 3 Effect of nutrient supplementation on protein production in yeast biomass.

BFPHM, Beles’ fruit peels hydrolysates medium; SBFPHM, supplemented Beles’ fruit peels hydrolysates medium; GSBFPM, glucose supplemented Beles’ fruit peels hydrolysates medium. From the above results it may be said that Beles’ fruit peels alone without supplementation of inorganic carbon and nitrogen sources can be a good medium for the growth of Saccaharomyces cerevisiae.

Data found from the present study illustrated that Beles’ fruit peel extracts contained variable ingredients such as ash content which reflects the presence of organic matter in the peels as organic compounds are natural substrate for microorganisms; crude fat contents which are needed in very minute amount; fiber contents which are also needed for the growth of the microorganism in small amount and carbohydrates, proteins, fats, minerals which are relatively supposed to be useful for the growth of yeast in the production of SCP. The findings of the present study for proximate chemical composition of Beles’ fruit peels were comparable with the results of various other studies7,12 even if the geographical study and the type and size of samples were different.

The effect of addition of nutrient supplements for yeast growth in the production of SCP was shown in Figure 3. The results clearly indicated that higher percentage of carbohydrate (63.5%) was found in yeast biomass when Saccaharomyces cerevisiae was grown on Glucose Supplemented Beles’ fruit peels Hydrolysates (GSBFPH) indicating that biomass yield can be increased when a carbon source like glucose is added to the medium. The similar observation had been reported by using the same yeast for the production of SCP from other fruit wastes.16 The low yield of protein (53.4%) obtained from BFPHM could be as a result of limited concentration of nutrients particularly carbon source required for microbial growth. This traces that the importance of supplementation to increase biomass yield. In contrast, protein content in fermented biomass was much lower (27.5% only) in Supplemented Beles’ fruit peels Hydrolysates (SBFPH) compared to that of in Beles’ fruit peels Hydrolysates Medium (BFPHM). Here, nitrogen supplementation decreased SCP production. Hence supplementation with inorganic nitrogen may have a suppressive effect on Saccaharomyces cerevisiae as the biomass yield was very low in the presence of these compounds.

In conclusion, promising yield of SCP production from S. cerevisiae was possible by submerged fermentation of Beles’ fruit peels. The degree of SCP production depends on the type of substrate used and media composition. The addition of glucose provided available carbon source for the organisms, thereby enhancing SCP production. The present finding discloses that Beles’ fruit peels were used as the potential source for the products with relatively higher carbohydrate and protein content by utilizing various ingredients available in them and there is a possibility of converting these Beles’ fruit peels to proteinaceous feed and food. Thus, these peels should be exploited properly as a substrate for the production of cellular biomass of edible yeast instead of dumping them as they can be used as a feed supplement with the least expense of money.

None.

Author declares that there is no conflict of interest.

©2015 Haddish. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.