Journal of

eISSN: 2572-8466

Research Article Volume 7 Issue 1

1Plant Science (Sugar Cane Production Technology), Jinka University, Ethiopia

2Plant Science (Professor of Genetics and Plant breeding), ArbaMinch University, Ethiopia

Correspondence: SemuYetaferu Ashagre, Plant Science (Sugar Cane Production Technology), Jinka University,Ethiopia

Received: December 17, 2019 | Published: January 23, 2020

Citation: Ashagre SY, Khan AQ. Determining optimum period of withholding irrigation for inducing maturity of sugarcane (Saccharum spp. hybrid) in Southern Ethiopia. J Appl Biotechnol Bioeng. 2020;7(2):16-25. DOI: 10.15406/jabb.2020.07.00211

Withholding irrigation before harvesting is important for inducing maturity in sugarcane. The study was carried out to determine the optimum period of withholding irrigation for inducing maturity in sugarcane in southern Ethiopia. Field experiments were conducted on two sugarcane varieties, N Co 334 and B 52 298 by five treatments of withholding irrigation periods for 20, 30, 40 50 and 60 days in randomized complete block design at the crop age of 11.3 months during 2014-15. The data on soil moisture content, top to bottom ratio of Brix in cane juice by hand refractometer, Brix, pol, purity and reducing sugars percent juice, and recoverable sugar percent cane, estimated sugar yield were recorded. Error variances for all characters except top to bottom ratio of Brix and reducing sugars in canes in experiments of both varieties were homogeneous and thus the data were also analyzed in split-plot design with varieties as the main plot and withholding irrigation period (WIP) treatments as subplots. The soil moisture percent differed at different WIPs with lowest at WIP for 60 days. Quality characters, top to bottom ratio of Brix in juice, Brix, pol or sucrose, purity, and sugar recovery percent cane increased significantly with the increase in WIPs, being highest at 50 and 60 days. Reducing sugars percent juice declined significantly with lowest at WIPs for 60 days. Estimated sugar yield increased significantly with the maximum at WIP for 50 and 60 days. The optimum period for withholding irrigation was 50 to 60 days for inducing maturity in sugarcane if not offset by rains. It was, therefore, suggestive that the irrigation could be withheld to sugarcane crop of about 12 months for 50 to 60 days but the quality of sugarcane should be determined before harvesting for obtaining maximum sugar yield in southern Ethiopia.

Keywords: withholding irrigation periods, soil moisture content, sugarcane quality characters, maturity

Sugarcane is a long duration crop and is harvested at maturity containing requisite sucrose, purity and sugar recovery percent cane. The maturity or ripening of sugarcane is influenced by the age of crop, day and night temperatures, atmospheric humidity, and the moisture content in the soil.1 At a given age and maturity, the lower internodes of cane stalks attain a genetically determined maximum sucrose concentration. The younger internodes of the cane stalks can be induced to accumulate high levels of sucrose by subjecting the crop to mild water stress by Singh & Naidu. The day and night temperature and the atmospheric humidity depend on the climatic conditions of the area. The age of the crop and soil moisture content can be managed by cultivation practices. Under unfavorable climatic conditions ripening in sugarcane is induced, either by withholding irrigation or by application of chemical ripeners.2 In areas of continuous sugarcane growth and unfavorable environmental conditions like high temperature and humidity, the maturity of the crop is delayed leading to an increase in the cost of production of sugarcane and sugar.3 The decrease in soil moisture content could reduce or check the growth of crops thereby effecting translocation of most of the photosynthates to the accumulation of sucrose in the sugar storing cells in the interior of cane stalk.4

Ripening of sugarcane by withholding irrigation before harvesting had been induced through a decline in soil moisture content in several countries. At Faisalabad, Pakistan Withholding irrigation for 30 days before harvesting enhanced sugar recovery by 1.37 % in November, 0.94 % in January and 5.53 % in March at Faisalabad, Pakistan.3 The length of withholding irrigation could differ with the climatic conditions of the countries for the improvement of sugar content and sugar yield by influencing the physiological process of cane stalks. The suspension of irrigation for two months before harvest gave the best results for soluble solids and sucrose content in South African sugar industries.5 The days required for pre-harvest drying off to improve sucrose accumulation in sugarcane could range from 30 to 150 days depending on low to high water holding capacity of the soil in Australia.6 Water could be withdrawn for a longer period in heavy soil than in the light soils.7 Sucrose might continue to be improved even after its peak concentration had been reached. For these reasons, the mechanism of withholding irrigation before harvesting at the maturity phase led to increases in sucrose accumulation.8 Optimal levels of plant desiccation had been estimated at a 4per cent reduction of the millable cane stalks or biomass.5 The economic benefit of increased sucrose accumulation from withholding irrigation before harvesting outweighed the minimal cane growth loss. Water stress during the maturity and ripening phase was beneficial and resulted in water savings and an increase in sucrose content in sugarcane stalk.9 A good understanding of the source-sink mechanisms of sugar accumulation could lead to both increased sucrose yields and water savings.

At Metehara sugar estate, Ethiopia, juice quality characters, Brix, pol, juice purity and estimated recoverable sugar and sugar yield increased significantly with the increase in the level of drying off period with a peak at 65 days. Sugar yield increased by 20.97 % by extending drying off period from 25 to 65 days with no further increase after drying off for 85 days.10 Withholding irrigation for 65 days at the harvest age of 15 months of ratoon crop of variety B 52 298 was recommended to increase sugar yield at Metahara Sugar Estate. In another study, Getaneh & Negi11 reported that drying off affected cane quality depending on soil moisture status and prevailing weather conditions. The agro-climatic conditions at Kuraz sugar project in southern Ethiopia where five new sugar factories are being established are favorable for the continuous growth of sugarcane year-round prolonging the maturity or ripening in sugarcane. Under such situations, withholding irrigation to sugarcane crops after the formation of millable canes could lead to an increase in sugar content in the cane due to a decline in moisture content in cane. Information on the optimum age of sugarcane harvesting was lacking in the tropical area at the new Kuraz Sugar Development Project, Ethiopia where five sugar factories are being established. Because of it, the present study was carried out to determine the optimum withholding irrigation period before harvesting of sugarcane for maximizing sugar production in southern Ethiopia.

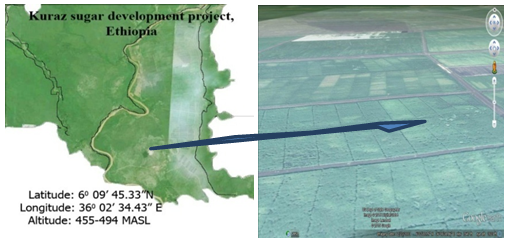

Descriptions of the study area: Study was conducted at Kuraz Sugar Development Project, Southern Nations and Nationalities People Region state, about 950 km away from Addis Ababa, the capital city of Ethiopia. The area lies between 50.57’ 39.90’’ to 60.15’36.65’’ North and 350. 56’ 12.90’’ to 360 01’ 16.02’’ East at an elevation ranging from 371 to 476 m above sea level. The area has a mean maximum and minimum monthly average temperature of 39.1 0C and 21.0 0C, respectively, and receives an average annual rainfall of 388 mm.

Soil characteristics of the experimental field: The average physical and chemical characteristics of soil in the adjacent fields of varieties, N Co 334 and B 52 298 are presented in Table 1. The textural compositions for silt, sand, and clay, and chemical properties for electric conductivity (EC), cation exchange capacity (CEC) and organic matter content (OM) of the soils were similar. Both the soils were heavy, known as Vertisols or clay soil (Figure 1). The pH of the soils was in the basic range. The soils had enough salts and organic matter contents and were suitable for growing sugarcane (Table 1 & Figure 2).

Varieties |

Soil Depth (cm) |

Texture (%) |

|

pH (1:5) |

EC (ds/m) (1:5) |

CEC (meq/100g) |

OM (%) |

|

Sand |

Silt |

Clay |

||||||

N Co 334 |

30 |

8 |

13 |

79 |

8.27 |

0.55 |

71 |

1.89 |

B 52 298 |

30 |

6 |

14 |

80 |

8.43 |

0.44 |

73 |

2.1 |

Table 1 Average physical and chemical characteristics of soil of adjacent fields of varieties at Kuraz Sugar Development Project during 2014-15

Figure 1 Geographical location of the study site of Kuraz Sugar Development Project.

Source: Google earth

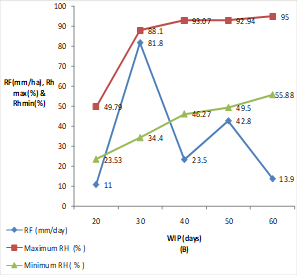

Figure 2 Trend of rainfall and maximum and minimum relative humidity at five withholding irrigation periods at kuraz sugar development project 2014/2015 yr.

Weather conditions during withholding irrigation: Average weather data for 10 days intervals during five withholding irrigation periods (WIPs) from March 20, 2015, to April 29, 2015, are provided in Table 2. The temperature varied from 40.69°C to 30.45°C, relative humidity from 49.79 %- 23.53 %. Rainfall fluctuated at WIPs and ranged from 11 mm at WIP for 20 days to 81.80 mm at WIP for 30days followed by less rainfall at WIP for 40, 50, and 60 days. The relative humidity increased at WIP for 30 days and maintained with little improvement at later WIPs. The occurrence of high mean day temperature at Kuraz would promote the growth of sugarcane and thus be likely to delay ripening in sugarcane varieties. The ripening in sugarcane is induced by temperature lower than 17.00°C. A mean day temperature of 12-14°C was considered desirable for proper ripening in sugarcane by Gururaj.12

Weather variables |

WIP (days) |

|

|

|

|

||

20 |

30 |

40 |

50 |

60 |

mean |

||

Air Temperature |

Max. (0c) |

40.69 |

36.88 |

35.16 |

34.36 |

33.9 |

36.2 |

Min. (0c) |

30.45 |

27.02 |

23.57 |

22.44 |

27.98 |

26.29 |

|

Sunshine |

(hr/day) |

0.39 |

0.31 |

0.3 |

0.38 |

0.3 |

0.33 |

Rainfall |

(mm/day) |

11 |

81.8 |

23.5 |

42.8 |

13.9 |

34.6 |

Evaporation |

Pan (mm/day) |

13.23 |

7.59 |

5.34 |

6.41 |

5.22 |

7.56 |

Pitch (ml/day) |

11.26 |

5.78 |

3.73 |

5.44 |

2.83 |

5.81 |

|

Eto (mm/day) |

9.17 |

5.31 |

3.74 |

4.68 |

3.65 |

5.31 |

|

Wind Speed |

day (m/s) |

2.39 |

2.16 |

1.69 |

1.4 |

1.75 |

1.88 |

night (m/s) |

17.33 |

1.7 |

1.4 |

0.98 |

0.71 |

4.43 |

|

Relative humidity |

Max. (%) |

49.79 |

88.1 |

93.07 |

92.94 |

95 |

83.78 |

Min. (%) |

23.53 |

34.4 |

46.27 |

49.5 |

55.88 |

41.91 |

|

Soil temperature |

at 0.05 m (0c) |

42.48 |

33.08 |

30.63 |

31.86 |

32.26 |

34.06 |

|

at 0.1 m (0c) |

35.53 |

31.82 |

29.8 |

30.69 |

30.85 |

31.74 |

Table 2 The average weather parameters per 10 days interval during the study period (27/02/2015 to 06/05/2015), at Kuraz Sugar Development Project

Materials and design of experiment: Materials were two recommended sugarcane varieties, N Co 334 and B 52 298 on which five withholding irrigation period treatments (WIPs) for 20, 30, 40, 50 and 60 days were effected in randomized complete block design with four replications. The plot for each WIP consisted of 8 rows of 8 m length spaced at 1.45 m between rows. The middle 6 rows of 8 m length represented the net plot size for the treatment in each replication. Variety N Co 334 was planted on 22.03.2014, whereas B52 298 was planted on 25.03.2014. The recommended cultural practices were followed to raise the crop of both varieties until the crops have attained the age of 11.3 months when the five withholding irrigation periods (WIPs) were effected. Before WIPs treatments put into effect, the experimental plots were irrigated on 25.02.2015. Three days after irrigation, assuming that field capacity of the soil has occurred, the days for withholding irrigation periods were effected as WIP for 20, 30, 40, 50 and 60 days before recording observations on the characters (Table 3).

|

Treatments |

Soil moisture (%) |

|

|

N Co 334 |

B 52 298 |

|

|

WIP (days) |

||

|

20 |

30.50d |

28.60d |

|

30 |

47.70a |

53.20a |

|

40 |

39.73b |

35.41c |

|

50 |

32.38c |

39.02b |

|

60 |

13.52e |

12.77e |

|

Grand Mean |

32.77 |

33.8 |

|

EMS |

1.09 |

1.3 |

|

SE (±) |

0.52 |

0.6 |

|

CD (at 5%) |

1.11* |

1.29* |

|

CV (%) |

3.19 |

8.94 |

Table 3 Soil moisture percent in fields of varieties at different WIPs at Kuraz Sugar Development Project during 2015

*Significant at 5 % level of significance (P=0.05).

Soil moisture content: Soil samples were collected from all five WIP treatment plots in each replication from randomly selected 6 spots at 30 cm depth to determine soil moisture content. From the mixed sample, 500 g soil sample was put into a metal can with lid and weighed. The soil in open can was dried in an oven at 105°C for about 24 hrs till constant weight was achieved. After drying and cooling in desiccator soil containing can with lid was weighed. The soil moisture content (%) was calculated by using the formula by Ryan.

, where, WWS is the weight of wet soil and WODS is the weight of oven-dried soil.

Top to bottom ratio Brix in juice: Top to the bottom ratio of Brix in cane juice was determined by hand refractometer, by extracting juice sample from top and bottom portion of cane stalks from each WIP treatment.

Brix percent cane: Brix percent cane was determined from composite juice of 10 randomly selected cane stalk samples from each of five WIP treatments. The cane stalks were cut into three portions to carry them for juice extraction. Cane samples were weighed and fed into Jeffco cutter–shredder crusher. The weight of shredded cane in1000 ml water and 10 ml of 5 percent solution of sodium carbonate blended for 10 minutes at 8,000 rpm was recorded. From it, a 100 ml portion of the extract of the juice sample was taken and 0.2 g filter-aid was added and stirred and filtered through Whatman No.6 by covering the funnel with a watch glass. The first 10 ml of running filtrates was discarded and the reading of Brix extract (Be) was determined with the precision of the reftractometer. Thereafter, Brix % cane was calculated following Hundito.13

,where, Bc represents Brix % cane, Be, Brix % extract and F, fiber % cane.

Pol percent cane: Pol percent cane was determined from the composite juice of 10 randomly selected cane stalk samples for each of five WIPs. 100 ml extracted sample juice was clarified by the addition of a small amount of dry basic lead acetate (0.5 g) and filter aid. After flocculation, the juice was filtered through Whatman No.91 by covering funnel with a watch glass. The first 25 ml of running filtrates were discarded and the rest filtrates were polarized in 200 mm Pol tube and the Pol reading recorded. From the Pol reading and Brix % per unit of extract (Be), the Pol % per unit extract (Pe) was noted from the Schmidt table. From the Pol % per unit extract (Pe), and fiber % cane, the Pol % cane (Pc) was calculated following Hundito.

, Where, Pc is Pol % cane, Pe, Pol % extract and F, fiber % cane.

Fiber percent cane: The direct fiber determination was applied following Hundito13 200 g of prepared fiberized cane sample was weighed into a beaker. A clean moist tray was placed on a balance and recorded its mass (M1). The fiberized material on the tray was transferred and dried in the oven at 110°C to 45 minutes and constant weight recorded (M2).

Dry substance % cane (D) = 100- moisture % cane

Fibre % cane, F = (D – 4 be) / (1 – 0.0125 be)

Purity percent: Purity percent juice was determined from the proportion of Pol percent per unit of an extract with the Brix percent per unit of extract or from the proportion of Pol percent cane with the Brix percent cane for each of five WIPs. Purity percent was calculated as: , Where, Pe, Pol % extract, Be is Brix % extract, Pc is Pol % cane, Bc is Brix % cane.

Estimated recoverable sugar: Recoverable sugar percent cane was calculated by using the Winter Carp indirect method of cane juice analysis14 , where, ERS is estimated recoverable sugar; NSF, the non-sugar factor (= 0.70); CF, the cane factor used both for the varieties N Co 334 and B 52 298 was 0.57.15

Estimated sugar yield: Sugar yield per hectare was calculated by multiplying the cane yield ton per hectare with estimated recoverable sugar at each of five WIPs (Sweet & Patel, 1985): Where ESY is estimated sugar yield, ERS is estimated recoverable sucrose (%) and CY is cane yield per hectare.

Estimated sugar yield per month: It was derived by dividing sugar yield per hectare with the age of sugarcane varieties at each of five WIPs (Sweet and Patel (1985): , where, ESYM is estimated sugar yield month, ESY is estimated sugar yield (Table 4).

|

Treatments |

SMC (%) |

|

Variety |

|

|

General Mean |

33.28 |

|

N Co 334 |

32.77b |

|

B 52 298 |

33.80a |

|

SE (±) |

0.17 |

|

CD (at 5%) |

0.523* |

|

WIP (days) |

|

|

20 |

29.55d |

|

30 |

50.45a |

|

40 |

37.57b |

|

50 |

35.70c |

|

60 |

13.15e |

|

EMS |

0.575 |

|

SE (±) |

0.27 |

|

CD (at 5%) |

0.55* |

|

Var*WIP |

79.83 |

|

CV (%) |

2.28 |

Table 4 Average soil moisture percent over fields of varieties at five withholding irrigation periods (WIPs) at Kuraz Sugar Development Project. During 2015

*Significant at 5 % (P=0.05), level of significance.

Reducing sugars: Reducing sugars (RSs) were determined from the clarified juice after the addition of neutral lead acetate in the cane juice by titration method using Fehling solution “A” and “B” and indicator methylene blue. Subtract sample titer from the average blank titer. Find reducing sugar content (expressed as dextrose) equivalent to the titer difference by reference to the accompanying noted for from Lane and Eynonys Method Table in Appendix Table 5.15

|

Treatments |

Characters |

|

|

|

|

|

|

|

|

WIP (days) |

TBR |

Brix (%) |

Pol (%) |

Purity (%) |

RSs (%) |

ERS (%) |

ESY (t/ha) |

ESYM (t/ha) |

|

20 |

0.7751c |

16.38d |

11.98c |

73.14c |

0.980a |

8.72d |

11.93c |

1.000d |

|

30 |

0.9127a |

17.25b |

12.38c |

72.75d |

0.890b |

8.85d |

12.53c |

1.022c |

|

40 |

0.8535b |

15.85d |

13.14b |

82.90b |

0.441c |

10.85b |

16.55b |

1.314b |

|

50 |

0.9402a |

18.19a |

16.20a |

88.19a |

0.246d |

14.32a |

19.95a |

1.544a |

|

60 |

0.8882b |

16.63c |

13.17b |

79.19c |

0.184d |

10.45c |

14.62b |

1.103c |

|

Grand Mean |

0.858 |

16.86 |

13.37 |

79.23 |

0.548 |

10.46 |

15.12b |

1.197b |

|

EMS |

0.002 |

0.3 |

0.2 |

6.74 |

0.14 |

0.0005 |

5.25 |

0.03 |

|

SE (±) |

0.02 |

0.28 |

0.22 |

1.3 |

0.01 |

0.19 |

1.15 |

0.09 |

|

CD (at 5%) |

0.05* |

0.59* |

0.47* |

2.77* |

0.02* |

0.40* |

2.44* |

0.19* |

|

CV (%) |

5.6 |

3.27 |

3.3 |

3.28 |

3.13 |

3.56 |

15.16 |

15.24 |

Table 5 Top to bottom ratio (TBR) of Brix in cane juice, Brix, Pol, purity and estimated recoverable sugar (ERS) percent cane, reducing sugars (RSs) percent juice, estimated sugar yield (ESY) and estimated sugar yield per month (ESYM) in N Co 334 variety at Kuraz Sugar Development Project during 2014-15

*Significant at 5% level of significance (P=0.05); Means with the same letter are not significantly different.

Statistical analysis: The data were subjected to analysis of variance by General Linear Models (GLM) procedure statistical analysis software package SAS16 following a procedure appropriate to the design of the experiment.17 Homogeneity of error variances for characters on both varieties experiments were tested by Hartleys’ F-max test for homogeneity of error variances. The data on all characters with homogeneous variances except top to the bottom ratio of juice and reducing sugars were analyzed in Split Plot design with varieties as the main plot and WIPs as sub-plots. The treatment means were separated by Duncan Multiple Range Test.

Soil moisture content at withholding irrigation periods

The soil moisture contents at five withholding irrigation periods (WIPs) for 20, 30, 40, 50 and 60 days differed significantly in fields of both varieties, N Co 334 and B52 298 (Table 3). The average maximum soil moisture content was recorded at WIP for 30 days followed by a decline in subsequent WIPs with a minimum at WIP for 60 days. This indicated that with an increase in withdrawing irrigation period there was a decrease in soil moisture content if it is not offset by the occurrence of rainfall. It may, however, be mentioned that high moisture content at WIP for 30 days than at WIP for 20 days was due to the occurrence of rainfall during the period. Moisture content in soil at any WIP was dependent on the initial soil moisture content, receipt of rain, water holding capacity of the soil and the atmospheric conditions such as air temperature and relative humidity. Withdrawing irrigation or drying off of field lead to a decrease in water content in cane which in turn could result in an increase of sugar content in cane. It could be variously affected by soil moisture-holding capacity, degree of drying and consequently the rate of ripening in cane fields.18 Similar to the present study, the soil moisture percent was observed to rise on the corresponding periods of moisture stress during the 6th, 8th and 10th weeks of moisture stress by Getaneh & Negi.11

Juice quality characteristics at different withholding irrigation periods (WIPs)

Top to the bottom ratio of Brix in cane juice: The top to bottom ratios (TBRs) of Brix in cane juice of variety N Co 334 were significantly higher at later WIPs than that at WIP for 20 days (Table 5). There were variable increases in TBRs at later WIPs. The TBRs of Brix at WIP for 30 and 50 days were significantly higher than at WIPs for 20, 40 and 60 days indicating an improvement in soluble solids or sugars in the top portion of juice. However, in variety, B 52 298, TBRs of Brix in juice at different WIPs were about 0.9 and statistically on par with each other (Table 6). This showed that soluble solids or sugars in the top portion of cane were slightly less than at the bottom portion indicating maturity of cane by WIP for 20 days. The closeness of TBR of Brix in cane juice to 1.0 was an indication of cane maturity. Harvesting of the cane on the basis of TBR of brix had been effective in crushing sugarcane in sugar mills in India.19

|

Treatments |

Characters |

|

|

|

|

|

|

|

|

WIP (days) |

TBR |

Brix (%) |

Pol (%) |

Purity (%) |

RSs (%) |

ERS (%) |

ESY (t/ha) |

ESYM (t/ha) |

|

20 |

0.9076a |

18.90a |

12.15d |

64.29d |

2.340a |

7.55d |

12.30c |

1.03c |

|

30 |

0.8905a |

16.34c |

13.06b |

79.93b |

1.780b |

10.44b |

16.87b |

1.41b |

|

40 |

0.9039a |

16.81c |

13.46b |

80.07b |

0.995c |

10.80b |

16.13b |

1.36b |

|

50 |

0.9080a |

16.04d |

12.39c |

77.24c |

0.987c |

9.56c |

15.44b |

1.29b |

|

60 |

0.9059a |

17.54b |

15.26a |

87.00a |

0.588d |

13.21a |

21.89a |

1.84a |

|

Grand Mean |

0.9032 |

17.13 |

13.26 |

77.71 |

1.338 |

10.31 |

16.54a |

1.39a |

|

EMS |

0.0004 |

0.31 |

0.19 |

6.5 |

0.004 |

0.2 |

9.81 |

0.07 |

|

SE (±) |

0.01 |

0.28 |

0.22 |

1.28 |

0.03 |

0.18 |

1.57 |

0.13 |

|

CD (at 5%) |

0.02NS |

0.59* |

0.46* |

2.72* |

0.06* |

0.39* |

3.34* |

0.26* |

|

CV (%) |

2.35 |

3.27 |

3.29 |

3.28 |

3.29 |

3.55 |

18.94 |

18.78 |

Table 6 Top to bottom ratio (TBR) of Brix in cane juice, Brix, Pol, purity and reducing sugars (RSs) percent juice, estimated recoverable sugar (ERS) percent cane, estimated sugar yield (ESY) and estimated sugar yield per month (ESYM) in B 52 298 variety, during the study period 2014/15 at Kuraz Sugar Development Project

*Significant at 5 % level of significance (P=0.05); NS indicates non-significant; Means with the same letter are not significantly different.

Brix percent cane: Brix percent cane in variety N Co 334 increased significantly at WIP for 30 days from that at WIP for 20 days. There was a further significant increase in Brix in cane at WIP for 50 days than all other WIPs. This indicated that Brix in cane amplified with an increase in days of WIPs with a maximum at WIP for 50 days (Table 5). In variety B 52 298, Brix at WIP for 20 days was maximum and significantly higher than later WIPs. The next higher Brix was recorded at WIP 60 days, which was significantly more than at WIP 30, 40 and 50 days (Table 6).

The average Brix over varieties by analysis in split-plot design was maximum at WIP for 20 days. The Brix in cane was lowest at WIP for 40 days with an increase at WIPs 30, 50 and 60, which were on par with each other (Table 7s). There was no set trend for Brix at WIPs though there was an increase in Brix from WIP for 30 and 40 days to WIP for 50 and 60 days with the exception at WIP for 20 days. It could possibly be due to sampling variation or due to the effect of variable moisture content in the soil because of variable rainfall at WIPs.

|

Treatments |

Characters |

|

|

|

|

|

|

Variety |

Brix (%) |

Pol (%) |

Purity (%) |

ERS (%) |

ESY (t/ha) |

ESYM (t/ha) |

|

Grand Mean |

16.99 |

13.32 |

78.47 |

10.48 |

15.83 |

1.29 |

|

N Co 334 |

16.86b |

13.35a |

79.23a |

10.46a |

15.12b |

1.20b |

|

B 52 298 |

17.13a |

13.26b |

77.71b |

10.31b |

16.54a |

1.39a |

|

SE (±) |

0.11 |

0.08 |

0.47 |

0.07 |

0.601 |

0.0497 |

|

CD (at 5%) |

0.33* |

0.25* |

1.45* |

0.212* |

1.8531 |

0.1531 |

|

WIP (days) |

||||||

|

20 |

17.64a |

12.07d |

68.71d |

8.14c |

12.12c |

1.02c |

|

30 |

16.80b |

12.72c |

76.34c |

9.65c |

14.69b |

1.22b |

|

40 |

16.33c |

13.30b |

81.49b |

10.82b |

16.37a |

1.34a |

|

50 |

17.12b |

14.30a |

82.72a |

11.93a |

17.70a |

1.42a |

|

60 |

17.09b |

14.23a |

83.10a |

11.83b |

18.25a |

1.47a |

|

EMS |

0.227 |

0.136 |

4.453 |

0.08 |

7.233 |

0.049 |

|

SE (±) |

0.17 |

0.13 |

0.75 |

0.11 |

0.95 |

0.08 |

|

CD (at 5%) |

0.35* |

0.27* |

1.54* |

0.23* |

1.96* |

0.16* |

|

Var*WIP |

29.03 |

71.56 |

34.48 |

120.01 |

5.69 |

5.81 |

|

CV (%) |

2.81 |

2.77 |

2.69 |

2.94 |

16.99 |

17.02 |

Table 7 Effect of withholding irrigation periods on Brix, Pol (sucrose) and purity percent juice and estimated recoverable sugar (ERS) percent cane, estimated sugar yield (ESY) and estimated sugar yield per month (ESYM) during the study period 2014/15 at Kuraz Sugar Development Project

*Significant at 5 % (P=0.05), level of significance; Means with the same letter are not significantly different.

As in the present study, increases in Brix and sucrose content of fresh and dry mass were recorded with age by Inman-Bamber & Muchow.20 However, contrary to the present study, Brix readings displayed a declining trend starting from the 6th week after withholding irrigation by Getaneh & Negi.11 This happened when the soil moisture level decreased substantially which could be attributed to the negative effect of drastic moisture stress. The interaction effect between varieties and WIPs could occur due to fluctuations in Brix at different WIPs in both varieties. Variety, N Co 334 exhibited increase in Brix at WIP for 30 days, decline at WIP for 40 days and steep decrease at WIP for 50 days and a sharp decline at WIP for 60 days. On the other hand, Brix percent juice of B 52 298 declined sharply from WIP for 20 days to WIP for 30 days with an increase and decrease at WIP for 40 and 50 days and conspicuous increase at WIP for 60 days (Table 8).

|

Treatments |

Characters |

|

|

|

|

|

|

Variety |

Brix (%) |

Pol (%) |

Purity (%) |

ERS (%) |

ESY (t/ha) |

ESYM (t/ha) |

|

Grand Mean |

16.99 |

13.32 |

78.47 |

10.48 |

15.83 |

1.29 |

|

N Co 334 |

16.86b |

13.35a |

79.23a |

10.46a |

15.12b |

1.20b |

|

B 52 298 |

17.13a |

13.26b |

77.71b |

10.31b |

16.54a |

1.39a |

|

SE (±) |

0.11 |

0.08 |

0.47 |

0.07 |

0.601 |

0.0497 |

|

CD (at 5%) |

0.33* |

0.25* |

1.45* |

0.212* |

1.8531 |

0.1531 |

|

WIP (days) |

||||||

|

20 |

17.64a |

12.07d |

68.71d |

8.14c |

12.12c |

1.02c |

|

30 |

16.80b |

12.72c |

76.34c |

9.65c |

14.69b |

1.22b |

|

40 |

16.33c |

13.30b |

81.49b |

10.82b |

16.37a |

1.34a |

|

50 |

17.12b |

14.30a |

82.72a |

11.93a |

17.70a |

1.42a |

|

60 |

17.09b |

14.23a |

83.10a |

11.83b |

18.25a |

1.47a |

|

EMS |

0.227 |

0.136 |

4.453 |

0.08 |

7.233 |

0.049 |

|

SE (±) |

0.17 |

0.13 |

0.75 |

0.11 |

0.95 |

0.08 |

|

CD (at 5%) |

0.35* |

0.27* |

1.54* |

0.23* |

1.96* |

0.16* |

|

Var*WIP |

29.03 |

71.56 |

34.48 |

120.01 |

5.69 |

5.81 |

|

CV (%) |

2.81 |

2.77 |

2.69 |

2.94 |

16.99 |

17.02 |

Table 8 Effect of withholding irrigation periods on Brix, Pol (sucrose) and purity percent juice and estimated recoverable sugar (ERS) percent cane, estimated sugar yield (ESY) and estimated sugar yield per month (ESYM) during the study period 2014/15 at Kuraz Sugar Development Project

*Significant at 5 % (P=0.05), level of significance; Means with the same letter are not significantly different.

Pol percent cane: Pol percent cane in variety N Co 334 was significantly more at WIP for 40 days than at WIP for 20 and 30 days. Pol percent cane at WIP for 50 days was significantly higher than that at the earlier WIPs and later WIP for 60 days (Table 5). In variety, B 52 298, there was a significant increase in Pol or sucrose percent cane at WIP for 30 and 40 days from that at WIP for 20 days. Pol percent cane was significantly higher at WIP 60 days than the earlier WIPs (Table 6). The results indicated that there was, in general, improvement in Pol percent cane with an increase of the days of WIPs in both varieties. Analysis over varieties in Split-plot design indicated that the average Pol percent cane increased significantly at every later WIPs. The results revealed that Pol percent cane increased with an increase in days for withholding irrigation periods from 20 days up to 50 or 60 days (Table 7). The results were in agreement with that reported by James14 that the accumulation of sucrose accumulation in cane could be enhanced by reduction of water supply in Australia, Zambia, and Zimbabwe. Under best ripening conditions a ton of sugar could be produced from 7 to 8 tons of canes. Oliver et al.,9 reported that water stress resulted in an increase of sucrose content in cane. In South Africa, Robertson & Donaldson5 reported increase in sucrose content up to 18 %. The optimum level of plant desiccation was estimated to be a 4 % reduction in the number of millable canes or biomass. Robertson and Donaldson reported that the drying off maximized sucrose accumulation and created easy access to the movement of machinery in the field for harvesting, in Australia. Thereby, they found that generally, drying off was more often associated with an increase in sucrose concentration, than with an increase in sucrose yield. According to Humbert21 inducing gradual soil moisture stress in a planned way could help in better and earlier ripening of cane due to the effect of moderate drought. It could subdue the activities of the cells and substantially retard vegetative growth, and as a result, the sugar would be stored rather than being used for further vegetative growth. Sucrose yields increased steadily despite the large changes in soil water content, that is, the stressed plots would have appeared to yield more sucrose than the unstressed plots.22

Purity percent cane: Purity percent cane in variety N Co 334 increased significantly at WIPs for 40 and 50 days from that WIPs for 20, 30 and 60 days. The purity per cent cane at WIP 50 days was significantly higher than all WIPs (Table 5). In variety B 52 298 purity percent cane increased significantly at every later WIPs with maximum and significantly more than all the earlier WIPs. Average purity percent cane over varieties increased significantly at subsequent later WIPs with purity at WIPs for 50 and 60 days is on par with each other (Table 6). The results revealed that purity percent cane with increasing days for WIPs with a maximum at 50 and 60 days.

This showed that the sucrose accumulation in cane was progressively increased with the increase in days for WIPs. This, in turn, indicated that the sucrose accumulation in the cane amplified with an increase in days of WIPs as noted for Pol percent earlier. However, contrary results were reported by Hemaprabha et al.23 Due to drought stress, the juice purity values in commercial varieties were observed lower because of wide differences between Brix and sucrose values in the juice of the clones at 360 days of crop age. From a two year study in Ethiopia, Getaneh and Negi reported that the drying off treatment exerted its effect on cane quality through its influence on soil moisture status, which in turn was dictated by soil moisture regime and prevailing weather conditions. Similarly, Yousef & Gholamreza.,24 reported that the juice purity was highest at the longest drying off period which was ascribed to the fact that the pol percent was higher with the longest drying off periods.

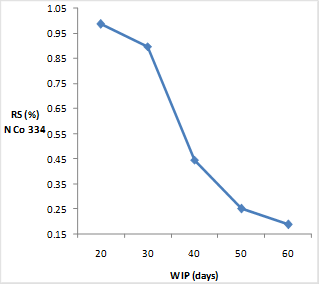

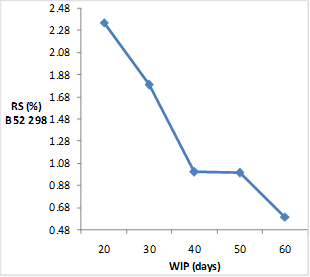

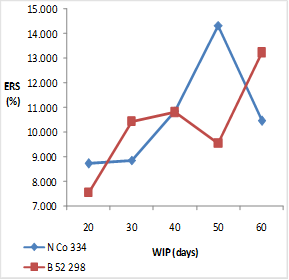

Reducing sugars percent juice: The reducing sugars in the juice of variety, N Co 334 declined significantly at every subsequent WIP from the highest at WIP for 20 days to lowest at WIP for 60 days (Figure 3). Reducing sugars in juice at WIP for 50 and 60 days was on par (Table 5). In variety B 52 298, reducing sugars percent juice also declined significantly from highest at WIP for 20 days to the lowest at WIP for 60 days (Figure 4). Reducing sugars in juice at WIP 40 and 50 were on par with each other (Table 6). Similar to the present results, higher levels of reducing sugars were reported in immature canes by Robertson et al.25 The results showed that reducing sugars composed mostly of glucose and fructose was used as building units into the biosynthesis of sucrose in the cane stalk.26 This phenomenon occurred when the sugarcane stalk tended to reach maturity thereby accumulating more sucrose in the sugarcane juice. The decreasing moisture content in the stalks, that is, dehydration forced conversion of reducing sugars to sucrose.27 The results, in turn, revealed that withholding irrigation in the sugarcane field after the formation of millable canes at the maturity stage had hastened the process of ripening in sugarcane. However, the maturity in sugarcane varies with the genotypes or clones. In one study Rakkiyappan et al.,28 reported that sugarcane clones showed variation in reducing sugars percent juice declining on the maturity of clones.

Figure 3 Trend of reducing sugar % at five withholding irrigation periods for N Co 334 at Kuraz Sugar Development Project (2014/15 yr).

Figure 4 Trend of reducing sugar % at five withholding irrigation periods in B52 298 at Kuraz Sugar Development Project (2014/15 yr).

Estimated recoverable sugar percent cane: In variety N Co 334 there was a significant increase in estimated recoverable sugar percent cane or sugar recovery percent cane at WIP 40 and 50 days than earlier WIPs 20 and 30 days. The maximum sugar recovery was recorded at WIP 50 days (14.32 %), which was significantly higher than the other (Table 5). In variety B 52 298, there was a significant increase in estimated sugar recovery at WIP for 30 and 40 days from lowest at WIP for 20 days. The maximum sugar recovery percent was recorded at WIP for 60 days, which was significantly higher than all other WIPs (Table 6). Analysis over varieties in Split-plot design also revealed that the average estimated recoverable sugar percent over varieties increased significantly at WIP for 40 days (10.82%) from that at WIPs for 20 (8.14%) and 30 days (9.65 %). Sugar recovery percent was significantly higher at WIPs for 50 (11.93%) and 60 days (11.83%) that the earlier WIPs (Table 7). The results indicated that the sugar recovery percent increased significantly by withholding irrigation from WIP for 20 days to WIP for 60 days as shown in Figure 5. Similar to the present results, withholding irrigation for about 30 days enhanced sugar recovery by 1.3 % in November, 0.94 % in January and 5.5 % in March, in Pakistan.3

Figure 5 The trend of interaction effects between varieties and WIPs for estimated recoverable sugar (ESR) percent at Kuraz Sugar Development Project (2014/15 yr).

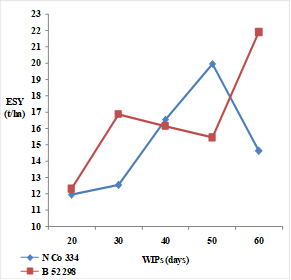

Estimated sugar yield: The estimated sugar yields ton/ha in variety N Co 334 was recorded significantly higher at WIP 50 days (19.95 ton/ha) than that at other WIPs for 20, 30, 40 and 60 days (Table 5). In variety, B 52 298, maximum sugar yield was recorded WIPs 60 days (21.89 ton/ha) which was significantly higher than that at the earlier WIPs (Table 6). Average sugar yield over varieties at WIPs for 40, 50 and 60 days in order were significantly higher than that of the earlier WIPs for 20 and 30 days (Table 7). This indicated that withholding irrigation before harvest increased sugar yield progressively with increasing the days of WIPs (Figure 6). These results are in agreement with others wherever withholding irrigation before harvests have been practiced in situations wherever the environmental conditions were not favorable for sugarcane ripening. The results are in agreement with Hagos et al.,10 reported the highest value of sugar yield at 65 days of drying off at Metehara sugar state in Ethiopia, with a marginal rate of return of 178.13 percents. They also reported the highest sugar yield at 15 months harvest age followed by a decline at 14 months age.

Figure 6 The trend of interaction effects between varieties and WIPs for estimated sugar yield (ESY) at Kuraz Sugar Development Project (2014/15 yr).

Estimated sugar yield per month: In variety N Co 334 estimated sugar yield per month (ESYM) at WIP for 40 and 50 days were significantly more than that at WIPs for 20, 30 and 60 days. The maximum sugar yield per month was recorded at WIP 50 days was maximum (1.54 tons/ha/month), (Table 5). In variety B 52 298, ESYM at WIP for 20 days (1.03 ton/ha/m) was significantly lower than that at other WIPs. ESYM at WIPs for 30, 40 and 50 days (1.41, 1.36 and 1.29 ton/ha/m) were on par with each other. Maximum ESYM was recorded at WIP 60 days (Table 6). The average sugar yield per month over varieties at WIPs for 40, 50 and 60 days were significantly more than those WIPs for 20 and 30 days (Table 7). The results revealed that there was an increase in sugar yield per hectare per month with an increase in the days of WIPs as noted above for sugar yield. A similar trend of results for sugar yield was reported by Renato et al.29 There was an increase in sugar yield with an increase of the days of treatments 0, 15, 30, 60 and 90 days of drying off before harvest.30

Conclusions: In the present investigation, the effects of five withholding irrigation period (WIPs) treatments, namely, WIP for 20, 30, 40, 50 and 60 days were studied in two sugarcane varieties, N Co 334 and B 52 298 in experiments conducted in randomized complete block design. The age of the crops of varieties N Co 334 and B 52 298 after the first WIP for 20 days were 363 and 360 days, respectively on March 22, 2015. The findings of this study are summarized as follows: The moisture content in the soil got reduced with an increase in days of WIPs recording thereby the lowest soil moisture at the WIP for 60 days as per expectation. However, the decrease in moisture content at 10 intervals from first WIP for 20 days to WIP for 50 days were off-set or obscured by the occurrence of rainfall during WIP for 30, 40 and 50 days.

There was a progressive increase in the top to the bottom ratio (TBR) of Brix in the juice of the cane stalks at different WIPs in variety N Co 334 reaching 0.9 at the last WIP for 60 days but TBR of Brix in variety B 52 298 reached 0.9 at all the WIPs indicating better juice quality. Brix percent in composite juice of cane varied between varieties at different WIPs. Analysis over varieties indicated that the Brix in the juice was significantly higher at latter WIPs for 50 and 60 days. Pol or sucrose percent juice in varieties was lowest at first WIP for 20 days which increased significantly subsequently at every WIP for 30, 40, 50 and 60 days in both varieties. The juice purity percent was low at first WIP for 20 days followed by significant increases at later WIPs for 40, 50 and 60 days.

An increase in quality parameters, namely, TBR of Brix, composite juice Brix and pol, and purity percent juice at subsequent WIPs indicated that withdrawing irrigation had improved the cane quality with the maximum reaching at WIP for 50 to 60 days.

Reducing sugars percent in the juice was maximum at first WIP for 20 days but these declined significantly at every subsequent WIP with lowest at WIP for 60 days. This indicated that withdrawing irrigation has led to an improvement in juice quality by the accumulation of more sucrose in juice at the last WIPs for 50 to 60 days. Estimated sugar recovery percent was recorded lowest at earlier WIP for 20 and 30 days but it increased significantly at latter WIPs for 40, 50 and 60 days. Estimated sugar yield tons per hectare was lowest at the first WIP for 20 days but there was a significant increase in sugar yields at every WIP for 30, 40, 50 and 60 days with a maximum at WIP for 60 days. Thus withdrawing irrigation for 60 days before the harvest was optimum for harvesting sugarcane in May at the Omo kuraz Sugar Development Project. As for estimated sugar yield tons per hectare, sugar yield tons per hectare per month was also lowest at first WIP for 20 days but it increased significantly at the latter WIPs for 40, 50 and 60 days. The maximum sugar yield per month was recorded at WIP for 60 days. Interaction between varieties and WIPs was observed for several characters due to fluctuations or non-correspondence in values between varieties at some WIPs.

Recommendation: Based on the overall results of the study on various quality parameters and sugar yields recorded at five withholding irrigation periods in two varieties of sugarcane, N Co 334, and B 52 298, the following conclusions are made. Withdrawing irrigation or not providing irrigation to the sugarcane crop after attaining full growth led to an improvement in cane quality and sugar yield. The optimum period for withdrawing irrigation from the well-grown crop was 50 to 60 days before harvesting sugarcane in May for obtaining maximum sugar yield per hectare. Irrigation from sugarcane crops should be withheld from March to May for 50 to 60 days for maximizing sugar production under the conditions of the South Omo Kuraz Sugar Development Project.

It should, however, be noted that if rainfall occurs during the withholding irrigation periods, the period of withholding irrigation should be extended till satisfactory juice quality of about 16 % sucrose and 80-85% juice purity in cane was obtained for good sugar recovery percent cane. The results on the effects of withholding irrigation periods on cane and quality characters studied for only one crop season during 2014-2015 were encouraging. Further study on withdrawing irrigation to grown-up sugarcane crops may be conducted for confirmations of the results and continued at different dates of plantations of sugarcane for determining optimum periods of withdrawing irrigation for an extended period of harvesting for increasing sugar production in the crushing season.

None.

No conflicts to declare.

None.

©2020 Ashagre, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.