Journal of

eISSN: 2572-8466

Research Article Volume 8 Issue 6

1Faculty of Agricultural Sciences, National University of Catamarca, Argentina

2Faculty of Agrarian Sciences, National University of the Littoral, Argentina

3National Council for Scientific and Technical Research, Argentina

4Faculty of Agronomy and Zootechnics, National University of Tucumán, Argentina

Correspondence: Di Barbaro Gabriela, Faculty of Agricultural Sciences, National University of Catamarca. Avda. Belgrano and Maestro Quiroga. Catamarca, Argentina

Received: October 22, 2021 | Published: November 12, 2021

Citation: Barbaro GD, Andrada H, Silvana BM, et al. Biofertilization of topinambur with Azospirillum brasilense and native mycorrhical fungi, cultivated in the Central Valley of Catamarca, Argentina. J Appl Biotechnol Bioeng. 2021;8(6):174-184. DOI: 10.15406/jabb.2021.08.00271

To evaluate the effect of Azospirillum and mycorrhizal soil fungi on the nutrition of the Jerusalem artichoke crop (Helianthus tuberosus L.), determinations of agronomic parameters and the health status of the plants were carried out under field conditions. The tests were carried out, at the time of the implantation of the culture: the "seeds" were inoculated with A. brasilense and with native mycorrhizal fungi, generating four treatments including the control and the co-inoculation of the consortium of the microorganisms under study (T0: control or uninoculated control; T1: inoculation with native A. brasilense; T2: inoculation with native mycorrhizal fungi and T3: joint inoculation with A. brasilense and native mycorrhizal fungi). The results indicate that co-inoculation with A. brasilense and native mycorrhizal fungi, significantly increased plant growth in height, leaf area, biomass, dry matter, and yields. It was determined that the application of the selected microorganisms has a promoting effect of plant growth, increasing the growth and productivity of the topinambur crop.

Keywords: interactions, mycorrhizae, jerusalem artichoke, Helianthus tuberosus

Helianthus tuberosus L., commonly known as topinambur, belongs to the botanical family Asteracea, and there are four main uses: horticultural, forage, inulin extraction and ethanol production.1–3

The topinambur could be considered a functional food due to its high inulin content.4 Inulin is considered a biological fiber, the ingestion of which confers several health benefits: it lowers the level of cholesterol in the blood, promotes the activity of bifidobacteria in the intestine, and reduces blood sugar.3,5,6

It is poorly digested by humans and therefore has the potential to be used in low calorie food formulations.7,8 Long inulin chains can be used to replace fat in foods, as they simulate its texture. This is used in the production of low-calorie dairy products.9 Inulin acts as a prebiotic, favoring the development of beneficial bacteria in the colon. The Jerusalem artichoke flour is gluten-free, which makes it suitable for celiacs and, in addition, has a reduced energy value. Ibarguren et al.,3 evaluated the potential of the topinambur as a food and observed that foods formulated with different proportions of topinambur are highly accepted by potential consumers and constitute a healthy alternative to the usual diet due to its high inulin content and the benefits that it provides contributes to human health.

The tubers of Jerusalem artichoke, in addition to having beneficial nutrients and fibers, also contain low levels of various chemical pollutants (insecticide residues; organophosphates, organochlorines, carbamates and pyrethroids), heavy metals (cadmium, lead, arsenic and mercury) and naturally toxic substances (nitrate, nitrite, cyanide, etc.). These levels are lower than those stipulated for food intended for human consumption by the Ministry of Public Health of Thailand, so they cannot cause any health problems and are considered healthy foods for consumers.10

The topinambur is an excellent double production forage, green forage, and tubers. The tubers are used as an energy reserve for the winter and are commonly used in pig feeding, which is why the topinambur is also called "potato chanchera".11

Numerous studies indicate the potential of topinambur to produce bioethanol.12–16 It has advantages over other crops, mainly due to its high biomass yield.16 Ethanol production can be carried out both from the aerial part and from the tubers.12,17

However, other uses are being investigated. As the topinambur is considered a highly invasive weed in European cultivation systems, the allelopathic potential of H. tuberosus was investigated, and the inhibitory capacity of its extracts on the germination and growth of weed and crop seedlings was discovered. that the implementation of integrated weed management programs has gained great interest, considering the suppressive capacity of topinambur and its residues for weed management in the field.18,19 Also, the use of Jerusalem artichoke leaf extracts was investigated for its potential use in improving the preservation of fruits and vegetables in storage. The results obtained imply that topinambur leaves could be a potential antimicrobial agent and source of natural fungicides.20 Willscher et al.,21 determined that H. tuberosus is a suitable plant for the phytoremediation of sites contaminated with heavy metals. On the other hand, Klímek et al.,22 investigated the viability of the residues of topinambur (H. tuberosus) and other agricultural crops to be used as alternative raw materials for boards, and due to their physical and mechanical characteristics, they determined that they are suitable to be used in production of furniture, since they comply with the European standard of conditions of use.

For all the, it is considered valuable to increase the production of topinambur through the incorporation of more productive and profitable cultivation technologies such as the use of biofertilizers, which in turn allows to reduce production costs and reduce the use of agrochemicals. Biofertilizers can contain one or more selected microorganisms, which can be applied to the seed or the soil to increase its density and its association with the root system of the plant to promote its nutrition. This improves the vegetative and productive development of the plant. Among the microorganisms most used for their potential contribution to plant development are the rhizobacteria A. brasilense and the arbuscular mycorrhizal fungus Glomus intraradices.23

Therefore, the objective of this work was to evaluate the effect of A. brasilense and native soil mycorrhizal fungi on the nutrition of the topinambur (H. tuberosus L.) crop, by determining agronomic parameters and the health status of the plants.

Two bioassays were carried out in the field. The treatments carried out on topinambur were: - T0: Control or control (without inoculation); - T1: Inoculation with A. brasilense; - T2: Inoculation with native mycorrhizal fungi; - T3: Joint inoculation with A. brasilense and native mycorrhizal fungi.

The inoculated treatments consisted of applying the selected microorganisms to the Jerusalem artichoke tubers, by immersing them in the inoculant just prior to implantation. While the tubers of the control treatments were placed in sterile running water. For the plantations, tubers of Jerusalem artichoke (H. tuberosus) of approximately 10 g of weight were used (Figure 1).

The native strain Pi8 of A. brasilense was used, isolated from the endorhizosphere of paprika (Capsicum annum var. Elephant trunk) cultivated in the Province of Catamarca, whose identification was carried out biochemically and molecularly.24–26 The concentration of A. brasilense used for the inoculations was 5x107 azospirilos. mL-1 quantified in a Neubauer chamber.27

The inoculum of mycorrhizal fungi native to the province was constituted by roots of Melilotus officinalis L., Avena sativa L., Hordeum vulgare L., Secale cereale L., Panicum maximun Jacq. and Cenchrus ciliaris L. colonized by these. The percentage of mycorrhizal colonization of the roots used as inoculum was 81.38%, estimated by the method of on-line intersections and microscopic observation of roots by Sieverding28 and Mc Gonigle et al.29

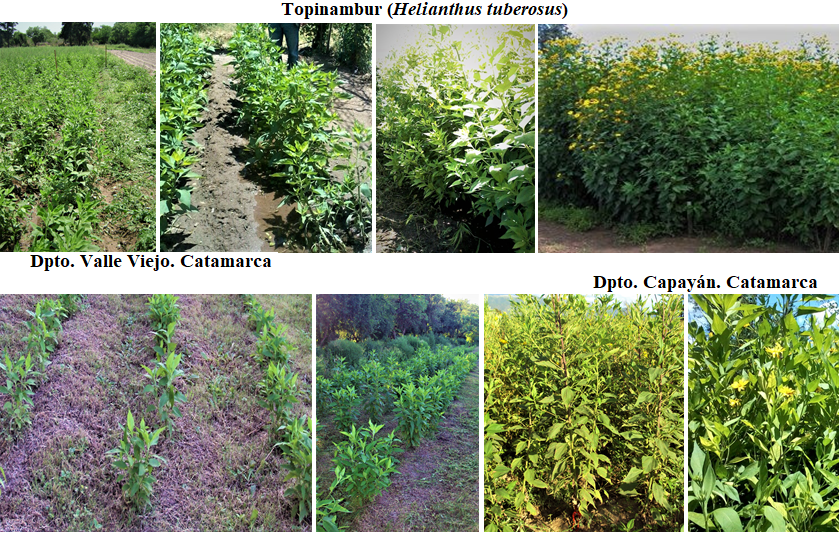

The bioassays were carried out in different localities of the Central Valley of the Province of Catamarca in Valle Viejo (28 ° 28'19.52 "S; 65 ° 43'54.40" W) and Miraflores (28 ° 35'22 "S; 65 ° 53 ' 45 "O) (Figure 2). The experimental design used was randomized blocks with three repetitions per treatment. Each repetition corresponded to a 3m x 3m plot with 25 plants (experimental units), in 5 cultivation lines 70 cm apart. Periodic evaluations of plant growth were carried out in different phenological stages of the topinambur crop. In each collection, 3 plants of each treatment and repetition were taken. In one of the topinambur experiments, collections were made at 118, 125, 139, 146, 153 and 180 days after implantation, and in another experiment at 147, 172, 192 and 222 days after sowing.

Figure 2 Trials of topinambur (Helianthus tuberosus) the localities of Valle Viejo and Miraflores, Catamarca (Argentina).

The following data were recorded on each evaluation date: plant height; number of stems; leaf area index (LAI),30 fresh weight (FW), dry (DW) and% DM of stems, leaves, roots, propagules, tubers, and whole plant; number of tubers per plant; average weight and tuber yield.

With the data of dry weight (DW) and fresh weight (FW) the% of dry matter (% DM = DW x 100 / FW) was calculated, both for stems, tubers, roots, and other parts of the plant. The results were statistically analyzed by analysis of variance (ANAVA) and the means were compared by Fisher's LSD (Least Significant Difference) test at a significance level of 0.05 using the Infostat statistical program.31

The cultivation of topinambur was developed in sites with sandy loam textural class soil. This crop does not thrive in waterlogged soils where the water stagnates for several days,32 they adapt to different types of soils, they grow without major problems in poor soils, but they develop better in fertile soils.1 The topinambur adapts to a relatively wide range of soil pH, production is favored in slightly alkaline soils,32 such as those found in the Central Valley of the Province of Catamarca.

Plant height: The inoculated topinambur plants (T1, T2 and T3), presented higher height throughout the crop cycle, registering statistically significant differences with respect to the control treatments (T0) (Tables 1&2). In the Miraflores topinambur crop, this variable was evaluated up to 192 days after implantation, because later the "delivery" of the crop occurred where the stems turned brown, dry, and brittle. However, magnitudes like those obtained in the experiments carried out by Rebora1 were recorded.

|

Treat. |

Variable |

Days after the implantation of topinambur (Valle Viejo) |

||||

|

118 |

125 |

139 |

146 |

153 |

||

|

Control |

Height (cm) Number FW (g) DW (g) DM (%) |

83,33+8,02 d 4,67+0,58 a 27,6+15,4 a 11,9+6,2 a 43,84+4,67 a |

153,0+11,5 b 9,0+1,0 a 55,4+12,6 a 24,7+7,9 a 43,77+5,06 b |

128,3+45,6 b 10,0+7,55 a 59,6+16,4 a 22,9+10,8 a 36,85+9,4 ab |

112,7+12,9 b 12,0+1,73 a 68,9+37,3 a 20,5+5,3 a 36,73+19,7 a |

113,7+26,1 c 7,67+2,52 a 53,7+39,5 a 19,4+12,3 a 40,99+17,1 a |

|

Azosp. |

Height (cm) Number FW (g) DW (g) DM (%) |

179,0+7,2 b 10,0+1,0 b 166,9+10,6a 43,2+4,7 a 25,86+1,36a |

192,0+3,0 a 9,33+0,58 a 114,4+14 a 36,9+1,9 a 32,46+2,61 a |

179,7+32 ab 8,67+0,58 a 128,7+25 ab 39,4+1,20 a 31,26+5,5 ab |

181,3+6,5 a 11,0+2,0 a 129,1+11 bc 37,7+4,2 bc 29,14+1,63 a |

152,3+12,5 b 7,33+2,89 a 98,8+50,5 a 36,4+7,4 a 40,9+14,9 a |

|

Myco. |

Height (cm) Number FW (g) DW (g) DM (%) |

113,7+13,9c 6,0+1,0 a 48,7+49,9a 16,2+12,4a 39,43+17,3a |

176,7+4,2 ab 9,33+1,53 a 119+9,5 a 35,1+1,3 a 29,58+1,46 a |

140,7+17 ab 9,0+3,61 a 177,8+64,9 b 70,1+27 b 39,13+1,68 b |

158,7+11 b 10,0+2,0 a 102,5+10 ab 29,2+4,3 ab 28,36+1,75 a |

161,7+10,3 b 7,33+0,58 a 93,5+41,8 a 32,9+7,4 a 39,22+17,0 a |

|

Azosp. +Myco. |

Height (cm) Number FW (g) DW (g) DM (%) |

201,3+6 a 14,33+2,52c 361,8+159 b 136,2+70,6b 36,29+6,92a |

181,3+22,7 a 10,67+2,08 a 144,5+28,3 b 40+3,9 b 28,09+3,10 a |

185,7+13,6 a 9,33+2,08 a 164,4+28,4 b 44,8+6 ab 27,47+3,82 a |

188,3+5,7 a 10,0+1,0 a 155,8+32,1 c 43,6+6 c 28,36+3,94 a |

196,7+7,6 a 5,67+3,51 a 92,9+44,6 a 33,7+8,9 a 40,61+13,7 a |

Table 1 Comparison of agronomic parameters of topinambur (height, quantity, dry matter, fresh and dry weight of stems) produced in the field of Valle Viejo Department

Uncommon letters in the same variable denote significant differences according to the LSD test (Minimum significant difference) for P <0.05.

|

Treat. |

Variable |

Days after the implantation of topinambur (Miraflores) |

|||

|

147 |

172 |

192 |

222 |

||

|

Control |

Height (cm) |

53,67+18,93 ab |

51,33+19,86 a |

67,67+49,05 a |

- |

|

Number |

6,67+4,04 a |

14,33+11,85 a |

11,33+8,39 a |

4,33+2,08 a |

|

|

FW (g) |

17,63+1,48 a |

26,73+17,78 a |

18,46+17,15 a |

4,90+3,80 a |

|

|

DW (g) |

6,35+1,72 a |

16,83+17,05 a |

12,07+11,45 a |

3,50+2,82 a |

|

|

DM (%) |

35,93+8,45 a |

53,28+22,45 a |

96,67+61,40 a |

65,36+13,45 a |

|

|

Azosp. |

Height (cm) |

52,00+13,23 a |

71,00+35,59ab |

60,33+30,66 a |

- |

|

Number |

8,00+4,36 a |

13,33+9,45 a |

22,33+2,52 b |

7,00+1,00 a |

|

|

FW (g) |

31,07+5,46 b |

40,34+10,43 a |

34,75+26,41 a |

14,83+10,13ab |

|

|

DW (g) |

11,55+1,33 a |

26,39+15,08 a |

23,06+18,38ab |

10,87+7,35 ab |

|

|

DM (%) |

37,52+4,25 a |

74,29+52,91 a |

63,99+5,07 a |

73,46+0,80 a |

|

|

Myco. |

Height (cm) |

82,33+18,72 bc |

108,67+22,03 b |

108,0+12,17 a |

- |

|

Number |

7,67+1,53 a |

8,33+4,04 a |

8,67+4,73 a |

8,00+6,24 a |

|

|

FW (g) |

46,44+0,53 c |

76,00+22,11 a |

41,96+16,41 a |

21,93+10,77 b |

|

|

DW (g) |

18,22+1,92 b |

39,16+12,38 a |

36,41+13,57ab |

16,40+8,94 b |

|

|

DM (%) |

39,22+3,69 ab |

56,05+25,78 a |

87,09+2,62 a |

73,40+5,11 a |

|

|

Azosp. +Myco. |

Height (cm) |

86,33+12.34 c |

97,33+23,01ab |

109,0+7,00 a |

- |

|

Number |

2,67+2,08 a |

16,33+10,97 a |

11,67+5,51 ab |

5,00+6,08 a |

|

|

FW (g) |

23,48+9,60 ab |

67,06+45,85 a |

54,89+22,11 a |

11,80+9,10 ab |

|

|

DW (g) |

11,44+5,30 a |

48,60+26,65 a |

42,15+14,88 b |

8,50+6,58 ab |

|

|

DM (%) |

47,96+3,55 b |

76,94+17,79 a |

77,66+6,87 a |

71,19+2,36 a |

|

Table 2 Comparison of agronomic parameters of topinambur (height, quantity, dry matter, fresh and dry weight of stems) produced in the Miraflores field

Uncommon letters in the same variable denote significant differences according to the LSD test (Minimum significant difference) for P <0.05.

Number of stems: During the development of the crop, plants with similar amounts of aerial stems were observed (Tables 1&2). However, in the first collection, statistically significant differences were recorded between the treatments, where the highest number of aerial stems were observed in the plants corresponding to the inoculation treatment with the microbial consortium of A. brasilense and mycorrhizal fungi (T3) (Table 1). Where the number of stems obtained was much higher than those observed in previous experiments.33

Percentage of dry matter of aerial stems: In almost all the collections there were no differences with statistical significance between the treatments (Tables 1&2), except for the first collection of the topinambur plants from Miraflores, in which, if detected significant statistical differences, with higher percentages of stem dry matter in plants inoculated with the microbial consortium (T3) (Table 2). The highest values of fresh weight of stems were observed in the inoculated plants (T1, T2 and T3), registering statistically significant differences, mainly in the phase of full vegetative growth (first collections), when the stems are more turgid and palatable (Tables 1&2). This is important to produce feed for swine, who prefer the stems of Jerusalem artichoke over leaves.

Similar behavior occurred with the dry weight of the stems, being able to reach an average of 700 kg.ha-1 of dry stems with the application of the microorganisms under study (T1 and T3) (Table 2), generating another benefit, since the dried stems of these crops are used in the generation of steam and electricity necessary for the ethanol manufacturing process,16 and low-cost fuel for the producer.

Number of tubers per plant: Statistically significant differences were determined between the treatments, where the inoculated plants generated a greater number of tubers (Tables 3&4). From the Valle Viejo experiment, the average quantity of plant topinambur tubers from the inoculated treatments is higher than those observed by Andrada et al.,34 but the number of tubers of the control plants are like those obtained by these investigators. While, in the Miraflores trial, the average number of inoculated plant tubers coincides with those observed by Andrada et al.,34 and the number of tubers from the controls was well below those reported by these researchers, who carried out their experiments in the Central Valley of the Province of Catamarca.

|

Treat |

Variable |

Days after the implantation of topinambur (Valle Viejo) |

||||

|

118 |

125 |

139 |

146 |

153 |

||

|

Control |

FW (g) DW(g) DM (%) Number AW (g) Yield(kg.ha-1) |

78,9+34,6 a 16,5+8,1 a 20,5+1,5 ab 10,7+4,2 a 7,3+0,5 a 149,2+10,5 a |

150,5+12,9 a 30,5+3,3 a 20,2+0,8 a 28,3+9,9 a 5,8+1,9 a 117,6+39,7 a |

132,3+74,5 a 27,8+15 a 21,3+1,2 a 17,3+11,2 a 8,3+1,9 a 168,6+38,5 a |

310,2+100,4a 55+14,6 a 18,5+4,8 a 19,7+5,1 a 15,6+2,3 a 318,8+45,9 a |

357,7+252,2a 71,8+50,5 a 20,1+0,1 a 20,7+11,1 a 15,9+3,9 a 324,5+80,7 a |

|

Azosp. |

FW (g) DW(g) DM (%) Number AW (g) Yield(kg.ha-1) |

472,9+2,8 b 107,5+2,6 b 22,7+0,4 ab/p> 43,7+6,5 b 11+1,6 ab 224,3+33,3ab |

373,4+16 d 78,3+1,1 c 21+0,6 a 24,0+3,6 a 15,7+1,8 c 321,3+37,7 c |

330,5+89,5 b 69+20,4 b 20,8+0,8 a 22,3+1,5 a 14,7+3,5 bc 300,2+71,1bc |

442,9+382,8a 104,1+69,6 a 26,1+4,8 b 40,3+7,6 c 10,9+8,9 a 222,3+181 a |

487,7+51,1 a 101,7+10,4 a 20,9+0,05 b 22,3+2,1 a 21,8+0,3 ab 445,4+5,7 ab |

|

Myco. |

FW (g) DW(g) DM (%) Number AW (g) Yield(kg.ha-1) |

120,1+27,1 a 22,9+10,4 a 18,35+4,9 a 12,7+2,5 a 9,9+4,1 ab 203,1+84,1ab |

201,2+15,1 b 53,6+10,4 b 26,5+3,7 b 23,3+3,5 a 8,7+0,7 b 177,3+13,9 b |

291,4+62,7 b 66,6+18,9 b 22,6+2,6 a 15,7+1,5 a 18,5+3,02 c 377,9+61,7 c |

318,2+43,1 a 65,3+10,6 a 20,5+0,6 ab 25+3 ab 12,9+2,9 a 263,3+58,1 a |

427,3+7,2 a 89+1,5 a 20,8+0,01 b 22,7+3,8 a 19,2+3,2 a 392+65,5 a |

|

Azosp. + Myco. |

FW (g) DW(g) DM (%) Number AW (g) Yield(kg.ha-1) |

872,2+344,1c 208,8+86,8 c 23,7+1,5 b 54,7+10,6 b 15,6+4,4 b 318,3+89,2 b |

236,9+21,4 c 52+4,7 b 20,95+0,4 a 39,7+2,1 b 5,98+0,5 a 122+10,8 a |

260,1+16,6 b 57,7+8,6 ab 22,13+2,2 a 26,3+9,9 a 11,0+4,6 ab 224,8+93,2ab |

308,5+75,4 a 68,4+12 a 22,4+1,4 ab 31,3+4,2 bc 9,8+1,2 a 199,4+24,9 a |

505,5+157 a 109+36 a 20,1+0,1 b 17,7+3,2 a 28,1+4,4 b 573,9+90,3 b |

Table 3 Comparison of agronomic parameters of topinambur (fresh and dry weight, dry matter, quantity, average weight, and tuber yield) produced in Valle Viejo

Uncommon letters in the same variable denote significant differences according to the LSD test (Minimum significant difference) for P <0.05.

|

Treat |

Variable |

Days after the implantation of topinambur (Miraflores) |

|||

|

147 |

172 |

192 |

222 |

||

|

Control |

FW (g) DW(g) DM (%) Number AW (g) Yield(kg.ha-1) |

40,14+34,43 a 8,03+6,88 a 20,00+0,01 a 5,33+3,79 a 5,60+4,39 a 819,2+702,7a |

61,41+47,29a 12,23+9,43 a 19,89+0,12 a 16,33+12,1 a 4,17+2,51ab 1253,3+965,1a |

251,84+175,01a 50,36+34,99 a 20,00+0,004 a 15,33+2,08 a 15,58+10,27 a 5139,5+3571,5a |

182,50+136,71 a 36,52+27,35 a 20,02+0,02 a 6,67+2,89 a 27,92+24,13 a 3724,5+2790,0a |

|

Azosp. |

FW (g) DW(g) DM (%) Number AW (g) Yield(kg.ha-1) |

38,70+48,08a 7,89+9,81 a 20,34+0,10 b 6,33+6,81 a 4,79+2,01 a 789,8+981,1a |

55,68+33,3 a 11,53+7,02 a 20,62+0,22 b 20,33+9,07 a 2,63+0,41ab 1136,4+679,5 a |

374,18+212,51a 51,01+55,66 a 14,48+10,83 a 26,67+2,89 a 14,05+8,40 a 7636,2+4336,8a |

320,57+237,27ab 64,77+45,66 ab 20,29+0,25 b 9,67+5,86 ab 29,04+10,23 a 6542,1+4842,2ab |

|

Myco. |

FW (g) DW(g) DM (%) Number AW (g) Yield(kg.ha-1) |

71,82+57,94 a 14,96+12,07 a 20,79+0,07 c 10,00+8,19 a 6,73+2,13 a 1465,8+1182,5a |

58,01+21,13a 12,10+4,37 a 20,88+0,10 b 33,67+18,58a 1,97+0,70 a 1183,9+431,1 a |

416,98+66,20 a 88,74+14,09 a 21,28+0,003 a 28,67+15,95 a 16,55+5,55 a 8509,8+1350,9a |

347,93+174,93ab 72,49+36,44 ab 20,83+0,0022 c 15,00+6,00 ab 22,34+4,73 a 7100,6+3569,9ab |

|

Azosp.+Myco. |

FW (g) DW(g) DM (%) Number AW (g) Yield(kg.ha-1) |

106,33+42,68 a 22,62+9,08 a 21,27+0,003d 13,33+6,03 a 8,40+2,16 a 2069,9+871a |

76,55+42,61a 16,43+8,92 a 21,58+0,53 c 16,33+7,57 a 4,56+0,40 b 1562,2+869,6 a |

338,35+75,58 a 74,35+17,92 a 21,91+0,55 a 26,00+6,56 a 13,14+1,27 a 6905,1+1542,3a |

584,0+26,09 b 124,27+5,57 b 21,28+0,003 d 17,00+2,0b 34,56+2,72 a 11918,3+532,41 b |

Table 4 Comparison of agronomic parameters of topinambur (fresh and dry weight, dry matter, quantity, average weight, and tuber yield) produced in the Miraflores field

Uncommon letters in the same variable denote significant differences according to the LSD test (Minimum significant difference) for P <0.05.

Weight of tubers per plant: The highest weights of tubers per plant of Jerusalem artichoke were recorded in the treatments with the inoculation of the microbial consortium of A. brasilense and mycorrhizal fungi (T3) and with the bacterial inoculation (T1), where differences were observed statistically significant between the microbial inoculation treatments and the controls, during the development of the cultures (Tables 3&4).

Percentage of dry matter of the tubers: A higher percentage of dry matter of tubers was determined from the inoculated treatments, mainly with the microbial consortium (T3), observing in most of the collections significant statistical differences with respect to the controls (T0) (Tables 3&4).

Average weight of the tubers: The topinambur tubers with the highest average weight were observed in the inoculated treatments and fundamentally in the last collections, registering significant statistical differences in most of the collections, with respect to the control treatment (Tables 3&4). In the Valle Viejo experiment, tubers of average 28 g in T3 were obtained after 5 months of cultivation, with a range of variation of average weight of tubers from 23.5 to 32.5 g. Meanwhile, in the Miraflores experiment, in the last collection (7.4 months), tubers of 34.5 g average were obtained in T3, with a range of variation of average weight of tubers from 31.8 to 37.2 g, weights similar to those obtained by Andrada et al.,34 who harvested 8 months after implantation and achieved tubers of 33 to 39 g, for which it is estimated that the anticipated harvest is the fundamental reason for the lower average mass of tubers, due to the fact that no the Valle Viejo experiment to the phenological phase of ripening of Jerusalem artichoke tubers characterized by the translocation of nutrients from the aerial part to the tubers.

Yield (kg or t of tubers per ha-1): In the harvest of mature tubers, the highest yields were achieved with the inoculation of the microbial consortium of A. brasilense and mycorrhizal fungi (T3), at which time significant statistical differences were recorded. in comparison to the control treatments (T0) (Tables 3&4).

In the Valle Viejo experiment, the highest average yield was estimated with the inoculation of the microbial consortium (T3) 5 months after the implantation of topinambur, achieving average increases of 76.8% with respect to the control treatment, while with the inoculation with A. brasilense (T1) increases of 37% and with the application of mycorrhizal fungi (T2) of an average 20.8%.

With co-inoculation (T3), average yields of 573.94 kg.ha-1 were achieved, varying from 483.6 kg.ha-1 to 664.2 kg.ha-1 (Table 3), magnitudes lower than those informed by the bibliography, which is due to the realization of a very early collection, 3 months before the traditional harvest. Meanwhile, in the Miraflores experiment, with the co-inoculation (T3), yields of greater than 11,000 kg.ha-1 were achieved, estimating a maximum of 12,500 kg.ha-1 (Table 4), magnitudes lower than those reported in the literature.1,16,35

However, H. tuberosus is a species with potential to produce energy and has advantages over other crops, mainly its high biomass yield, which can produce 100 to 130 t of tubers per ha.36 There is information that indicates that 4500 l of ethanol can be obtained from 50 tonnes of Jerusalem artichoke tubers.16 The yields achieved indicate that more than 1000 liters of ethanol could be obtained per hectare of topinambur cultivation. Research carried out in Spain indicates that 1 l of ethanol can be obtained from 12 kg of Jerusalem artichoke tubers.37

Fresh weight of leaves per plant: The highest production of foliar mass was recorded in the inoculated topinambur plants, establishing differences with the control with statistical significance in the phenological stage of vegetative growth (Tables 5&6), characterized by the production of leaves and stems, an important quality for the development and yield of the crops.

Treat |

Var. |

Days after the implantation of topinambur (Valle Viejo) |

|

|||

|

|

118 |

125 |

139 |

146 |

153 |

Control |

FW (g) |

31,5+19,8 a |

63,49+8,56 a |

53,74+19,92 a |

44,84+21,4 a |

31,78+19,2 a |

DW(g) |

15,7+8,7 a |

26,58+14,6 a |

21,25+12,4 a |

22,33+10 a |

16,65+9,6 a |

|

DM(%) |

51,58+9,8 c |

40,33+19,7 a |

37,32+9,8 b |

50,47+2,2 b |

52,42+4,9 a |

|

LAI(cm 2) |

1761+1105a |

3549,3+478 a |

3004,1+1114 a |

2506,4+1197 a |

1776,3+1074 a |

|

Azosp. |

FW (g) |

197,9+2,7 b |

120,95+17,8 b |

113,23+2,7 b |

103,7+21,7 bc |

76,62+33,2 a |

DW(g) |

60,77+6,8 bc |

28,65+1,55 a |

28,99+1,4 a |

37,31+2,4 b |

28,73+6,9 a |

|

DM(%) |

30,8+3,9 ab |

23,9+2,2 a |

25,61+1,3 a |

36,83+6,3 a |

41,04+13,3 a |

|

LAI(cm 2) |

11060+150 b |

6761,2+994 b |

6329,4+151 b |

5798+1212 a |

4283+1853 a |

|

Myco. |

FW (g) |

58,47+47,4 a |

101,39+8,6 b |

91,89+14,9 ab |

87,09+12,2 b |

57,93+25,5 a |

DW(g) |

32,02+33 ab |

31,47+2,6 a |

25,99+3 a |

30,19+3,4 ab |

28,58+8,1 a |

|

DM(%) |

46,24+16 bc |

31,05+0,3 a |

28,45+1,5 ab |

35,41+8,6 a |

50,43+3,2 a |

|

LAI(cm 2) |

3269+2650a |

5668+483 b |

5137+830 ab |

4868,2+683 b |

3238+1428 a |

|

Azosp. +Myco. |

FW (g) |

339+109 c |

123+14,8 b |

121,6+33 b |

128,7+17,7 c |

81,5+48,2 a |

DW(g) |

92,28+27,9 c |

33,34+5,1 a |

35,26+8,3 a |

35,63+5,3 b |

24,15+9,7 a |

|

DM(%) |

27,39+0,92 a |

27,04+1,2 a |

29,2+1,3 ab |

27,67+0,6 a |

34,84+13,2 a |

|

|

LAI(cm 2) |

18949+6103c |

6874+827 b |

6798,4+1844 b |

7192+993 c |

4554,8+2695 a |

Table 5 Comparison of agronomic parameters of topinambur (fresh weight, dry weight, dry matter of leaves and leaf area index) produced in the Valle Viejo field

Uncommon letters in the same variable denote significant differences according to the LSD test (Minimum significant difference) for P <0.05.

Treat. |

Variable |

Days after implantation (Miraflores) |

|

|

|

|

|

147 |

172 |

192 |

222 |

Control |

FW (g) |

22,57+4,5 a |

35,96+23,4 a |

17,31+14,8 a |

0,37+0,15 a |

DW(g) |

9,67+2,2 a |

11,22+8,6 a |

14,37+12,2 a |

0,37+0,06 a |

|

DM(%) |

43,37+10,7 a |

28,87+5,7 a |

106,55+42,1 a |

110,00+36,1b |

|

LAI(cm 2) |

1261,5+248,6 a |

2010,4+1307,4a |

967,83+824,7a |

20,50+8,5a |

|

Azosp. |

FW (g) |

38,61+11,7 ab |

50,21+44,9 a |

33,28+28,2 a |

1,83+0,25 b |

DW(g) |

14,75+4,1 a |

19,43+13,2 a |

29,13+25,8 a |

1,4+0,26 a |

|

DM(%) |

38,58+5,99 a |

71,16+65,5 a |

83,77+6,7 a |

76,29+8,3 ab |

|

LAI(cm 2) |

2158,1+652,6ab |

2806,6+2507,4a |

1860,19+1576,7a |

102,48+14 b |

|

Myco. |

FW (g) |

44,48+17,4 b |

45,22+26,9 a |

14,59+9,01 a |

1,67+1,4 ab |

DW(g) |

18,61+8,76 a |

22,47+11,36 a |

14,26+8,4 a |

1,50+1,39 ab |

|

DM(%) |

40,62+5,36 a |

55,57+18,3 a |

99,05+3,2 a |

88,89+14,3 ab |

|

LAI(cm 2) |

2486,5+974,1b |

2528+1506 a |

815,59+503,8 a |

93,17+80,3 ab |

|

Azosp. |

FW (g) |

19,15+6,34 a |

67,32+37,9 a |

35,88+17,02 a |

0,63+0,5 ab |

+Myco. |

DW(g) |

10,38+2,23 b |

36,34+26,7 a |

34,32+16,7 a |

0,32+0,2 a |

DM(%) |

57,01+17,7 a |

51,92+12,04 a |

94,84+4,6 a |

56,67+12,8 a |

|

|

LAI(cm 2)) |

1070,5+354,1 a |

3763,4+2116,1 a |

2005,71+951,5 a |

35,40+25,8 ab |

Table 6 Comparison of the agronomic parameters of topinambur (fresh weight, dry weight, dry matter of leaves and leaf area index) produced in the Miraflores field

Uncommon letters in the same variable denote significant differences according to the LSD test (Minimum significant difference) for P <0.05.

Percentage of dry matter of leaves: In most of the collections there were no statistically significant differences between the treatments for this variable (Tables 5&6). However, in the Valle Viejo experiment, in two collections, the highest percentages of dry matter were recorded in the control plants (T0), which may indicate the lower speed of translocation of nutrients and photosynthates from the leaves to the tubers, fundamentally.

Leaf area index (LAI): The highest LAI was obtained in the inoculated treatments, mainly with T3, during the vegetative growth period of the crop, registering statistically significant differences between the inoculated treatments compared to the control treatments (Tables 5&6). As the crop evolves, the temperature drops and winter approaches, the leaves of the topinambur plants turn yellowish and droopy, which is why the number of leaves and consequently the LAI decreases. The higher production of leaves of the inoculated treatments, evidenced by the variables evaluated, explain the higher production of photosynthates and its direct effect on the growth of the crops.

Root dry matter percentage: The highest root dry matter production was obtained in the inoculated plants, with significant statistical differences between the inoculated treatments in comparison with the controls (Tables 7&8). Because the highest fresh and dry root biomass was observed in the inoculated treatments, in magnitudes much higher than the controls, results that show the growth-promoting activity of the roots of the microorganisms under study.

Treat. |

Variable |

Days after the implantation of topinambur (Valle Viejo) |

||||

118 |

125 |

139 |

146 |

153 |

||

Control |

FW (g) DW(g) DM (%) |

18,11+9,1 a 8,19+4,1 a 33,09+19,9 a |

40,3+3,8 a 8,86+1,8 a 21,84+2,5 a |

34,42+15,7 a 12,36+8,7 a 32,85+16,8 a |

40,26+5,92 a 12,01+3,7 a 29,40+4,8 a |

35,92+19,8a |

Azosp. |

FW (g) DW(g) DM (%) |

68,53+2,43ab 17,14+2,35 a 24,95+2,6 a |

79,5+2,7 b 22,11+2,2 b 27,77+1,8 b |

69,87+27,4ab 19,11+7,9 a 27,15+1,7 a |

79,36+22 bc 18,16+2,95 b 23,48+3,3 a |

30,67+9,6 a 13,24+7,6 a 41,04+10,4a |

Myco. |

FW (g) DW(g) DM (%) |

21,93+15,1 a 9,22+7,53 a 37,54+20,9 a |

73,87+10 b 16,39+3,8 b 22,06+2,6 a |

44,18+11,4 a 12,99+4,5 a 28,87+3,2 a |

47,34+10,4ab 11,46+1,81 a 24,53+2,9 a |

34,84+14,2a 11,78+5,7 a 33,32+3,4 a |

Azosp. +Myco. |

FW (g) DW(g) DM (%) |

117,2+66,4 b 41,22+21,24b 36,63+3,9 a |

104,8+14,1c 23,51+3 c 22,44+0,4 a |

102,6+44,9 b 25,16+8,6 a 25,49+3,4 a |

112,6+26,3 c 27,15+2,96 c 24,62+3,2 a |

46,12+17,9a 16,37+6,7 a 35,23+1,5 a |

Table 7 Comparison of the agronomic parameters of topinambur (fresh weight, dry weight and dry matter of roots) produced in the Valle Viejo field

Uncommon letters in the same variable denote significant differences according to the LSD test (Minimum significant difference) for P <0.05.

Treat. |

Variable |

Days after implantation (Miraflores) |

|||

147 |

172 |

192 |

222 |

||

Control |

FW (g) DW(g) DM (%) |

21,06+3,9 ab 7,51+0,9 a 36,74+9,1 a |

145,55+94,9 a 12,66+5,1 a 10,82+5,4 a |

26,83+21,6 a 7,75+5,1 a 49,79+39 a |

15,67+15,7 a 6,17+5,9 a 42,99+6,2 a |

Azosp. |

FW (g) DW(g) DM (%) |

23,24+8,9 ab 9,67+3,5 a 41,80+3,6 ab |

236,33+155,3 ab 21,85+17,5 a 18,14+24,4 a |

57,60+37,8 a 25,70+19,01 a 45,05+11,45 a |

37,90+28,03 ab 19,63+14,6 ab 50,18+4,9 a |

Myco. |

FW (g) DW(g) DM (%) |

31,81+11,8 b 11,11+2,3 a 36,51+7,9 a |

428,57+190,2 b 23,51+13,8 a 6,95+6,6 a |

41,96+16,4 a 36,41+13,6 a 87,09+2,6 a |

64,20+26,5 ab 34,03+16,7 ab 51,41+7 a |

Azosp. |

FW (g) DW(g) DM (%) |

13,28+6,9 a 6,48+3,2 a 49,10+3,6 b |

181,92+81,15 ab 29,04+13,6 a 17,23+6,9 a |

74,04+69 a 34,00+29,45 a 46,92+10,65 a |

80,87+30,6 b 43,30+20,8 ab 52,62+6,8 a |

Table 8 Comparison of agronomic parameters of topinambur (fresh weight, dry weight, and dry matter of roots) produced in the field of Miraflores

Uncommon letters in the same variable denote significant differences according to the LSD test (Minimum significant difference) for P <0.05.

The evaluations of whole plants during the development of the culture showed a greater growth of the inoculated plants throughout their cycle, registering significant statistical differences with respect to the control (Tables 9&10).

Treat. |

Variable |

Days after the implantation of topinambur (Valle Viejo) |

|

|||

|

|

118 |

125 |

139 |

146 |

153 |

Control |

FW (g) |

156,2+75,4 a |

309,8+37,9a |

280+121,1a |

464,2+163,9a |

479,1+305,1a |

DW(g) |

50,3+26,2 a |

90,6+26,4a |

84,3+44 a |

109,9+26,4 a |

119,1+74,6 a |

|

DM (%) |

31,7+2,6 a |

28,8+5,5 a |

28,9+4,3 a |

24,6+3,8 a |

25,3+1,2 a |

|

Azosp. |

FW (g) |

906,1+10,6 b |

688,2+50,4 c |

642,3+95,7 b |

755,1+332,3a |

693,8+124,4a |

DW(g) |

228,6+5,6 a |

166+6,6 b |

156,5+28,6 b |

197,2+61,1 b |

180,1+20,9 a |

|

DM (%) |

25,24+0,8 a |

24,2+0,9 b |

24,3+1,34 a |

27+3 a |

26,1+1,5 a |

|

Myco. |

FW (g) |

249,1+70,4a |

495,4+42,5b |

605,2+50,1 b |

555,1+25,6 a |

613,6+77,7 a |

DW(g) |

80,3+38 a |

136,5+17,5b |

162,3+45,3 b |

136,1+7,6 ab |

162,3+15,6 a |

|

DM (%) |

31,1+6,9 a |

27,5+1,2 a |

26,7+6,18 a |

24,52+0,8 a |

26,5+1,1 a |

|

Azosp. +Myco. |

FW (g) |

1690+676 c |

609,2+77,7 c |

648,8+119,5b |

705,5+50,6 a |

726+266,5a |

DW(g) |

478,5+206 b |

148,9+16,5b |

162,9+31,4 b |

174,8+3,6 b |

138,6+65,8 a |

|

|

DM (%) |

27,9+1,8 a |

24,47+0,58a |

25,1+1,55 a |

24,84+1,5 a |

20,5+9,2 a |

Table 9 Comparison of agronomic parameters of topinambur (fresh weight, dry weight, and dry matter of the whole plant) produced in the Valle Viejo field

Uncommon letters in the same variable denote significant differences according to the LSD test (Minimum significant difference) for P <0.05.

Treat. |

Variable |

Days after implantation (Miraflores) |

|

|

|

|

|

147 |

172 |

192 |

222 |

Control |

FW (g) |

101,40+33,1 a |

218,37+207 a |

314,44+227,3 a |

203,43+152,7 a |

DW(g) |

31,56+11,3 a |

52,94+39,9 a |

84,55+62,5 a |

46,55+34,9 a |

|

DM (%) |

30,87+1,9 a |

27,68+11,6 ab |

26,53+1,3 ab |

23,10+0,8 a |

|

Azosp. |

FW (g) |

131,12+43,6 a |

382,57+146,7 ab |

499,80+301,4 a |

375,13+272 ab |

DW(g) |

43,86+12,3 ab |

79,19+23,1 a |

128,91+111,8 a |

96,67+68,5 a |

|

DM (%) |

33,72+2,7 a |

21,21+2,7 ab |

25,11+9,3 a |

26,39+1,5 a |

|

Myco. |

FW (g) |

194,55+64,3 a |

607,80+197,6 b |

523,90+71,2 a |

435,13+272 ab |

DW(g) |

62,90+20,2 b |

97,24+39,03 a |

160,50+33 a |

124,42+15 ab |

|

DM (%) |

32,43+0,7 a |

16,85+8,1 a |

30,57+4,3 ab |

30,42+8,5 a |

|

Azosp. +Myco. |

FW (g) |

162,23+64,3 a |

392,85+166,6 ab |

503,16+97,6 a |

677,30+61,4 b |

DW(g) |

50,92+18 ab |

130,41+76 a |

184,81+50,3 a |

176,40+29,5 b |

|

|

DM (%) |

31,69+3 a |

32,77+8 b |

36,76+6,6 b |

25,93+2,2 a |

Table 10 Comparison of the agronomic parameters of topinambur (fresh weight, dry weight, and dry matter of the whole plant) produced in the field of Miraflores

Uncommon letters in the same variable denote significant differences according to the LSD test (Minimum significant difference) for P <0.05.

The total biomass of topinambur plants from the co-inoculation treatments with the microbial consortium (T3), were significantly appreciable, achieving an average of the two experiments, 14,320 kg.ha-1.

Although the results obtained are in many cases inferior to those achieved in other parts of the world, there are also many reasons that can explain the differences. The topinambur crop has a good water demand (greater than 800mm), but it can survive long periods of drought, its productivity being significantly affected under these conditions.38 These circumstances are frequent in the central valley of the Province of Catamarca, immersed in the semi-arid region with problems of access to irrigation water. Furthermore, there is a direct relationship between tuber size and plant productivity.

However, the results obtained showed an increase in the different variables of vegetable production evaluated (plant height, number of tubers and propagules, fresh weight and dry weight of stems, roots, and tubers) in topinambur plants because of inoculation with native microorganisms of A. brasilense and mycorrhizal fungi, registering significant statistical differences with respect to the control plants without inoculation. Therefore, the highest productivity of these crops is obtained through the microbial inoculation of the "seeds" (tubers) at the time of the implantation of the crop.

The microbial consortium used, made up of native, bacterial, and fungal strains, generated the best results due to the greater intake of water and nutrients, and mainly nitrogen that can be incorporated into the soil by biological nitrogen fixation, since the bacterium A. brasilense has this capacity, in addition to synthesizing auxins and other phytohormones.39 The greater uptake of water and nutrients, especially those that are not very mobile such as phosphorus, facilitate their availability and assimilation by plants.40–43 Furthermore, these microorganisms locate and colonize sites in the rootlets, which could potentially be occupied by phytopathogens.44

The selection of effective microorganisms in promoting the growth of cultures is a great challenge. The adaptation to the environment to which they are introduced and the compatibility between the microorganisms that make up the microbial consortia and these with the plants, may be the factors that prevent their use in agricultural production.

This work contributes to making evident the potential of the selected microorganisms as an alternative to improve the nutrition and productivity of the topinambur crop. These results could support the possible use of microbial inoculants in the production of this crop, which would avoid or reduce the use of chemical fertilizers. They also indicate that there was a direct effect of microbial inoculation on the growth and yields of the topinambur culture. In addition, it is important to point out that these microbial interactions with topinambur roots were achieved with native microorganisms and that the crops were carried out in lots with no previous production history of these crops, added to the fact that it is a non-traditional crop in the province and that it is produced almost exclusively by a single farmer in the Central Valley area of Catamarca.

None.

There are no financial conflicts of interest.

None.

©2021 Barbaro, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.