International Journal of

eISSN: 2573-2838

Research Article Volume 5 Issue 3

1Universidad Nacional, Costa Rica

2Laboratorio Nacional de Nanotecnología LANOTEC-CeNATCONARE, Costa Rica

Correspondence:

Received: April 01, 2019 | Published: May 7, 2019

Citation: Alpizar-Vargas L, Zúñiga-Montero C, Rodríguez-Murillo A, et al. Nutraceuticals: definition, applied nanoengineering in their production and applications. Int J Biosen Bioelectron. 2019;5(3):56-61. DOI: 10.15406/ijbsbe.2019.05.00154

Background: Nutraceuticals can be defined as nutritional components that provide therapeutic or physiological benefits beyond the basic nutritional needs and include a wide range of compounds. However, they show very low bioavailability due to limited bio-accessibility, poor absorption and/or chemical transformation within the gastrointestinal tract. This renders their health benefits extremely difficult to be realized by the consumers. The present review shows the nanoengineering process involved in their production, starting from the materials used in the encapsulation, the process of nanoencapsulation, the principal encapsulation techniques used and the function of lipids, carbohydrates and proteins at the nanoencapsulation. Besides, this review gives the recent innovations and applications known using nutraceuticals.

Keywords: nutraceuticals, nanoencapsulation, applications, health, nanoengineering

Nutraceuticals include a wide variety of products, commonly sold through wellness and traditional medicine industries it represents a global market of around US$3.7trillion a year.1 Nutraceuticals are nutrients from natural sources with pharmaceutical-like effects. Dietary supplement companies and nonprofessional people often promote nutraceutical products with impressive and unbelievable properties but they lack of proper scientific evidence that back these claims. This cause that many healthcare and medical professionals are skeptical about nutraceuticals but there is evidence that some of this work but need a stricter regulatory process and more investigation before being recommended to treat a disease.2 Gradually the nutraceuticals are gaining popularity in the treatment of different health disorders. Recently, scientists found evidence that nutraceuticals work in the treatment of endocrine disorders3 and in the treatment of cancer.4 However, it is necessary to develop delivery systems as is done with common pharmaceutical products, due to the fact that some nutrients degrade inside the body which affects their response compared to laboratory tests. Another important aspect for which a good delivery is necessary are the recommended doses of the compounds of the nutraceuticals, any substance in excess can compromise health or in the opposite case a low dose can generate a null reaction. A way to achieve a good delivery is encapsulating the active ingredients, using this process establish a stable transport of the mass and control of the diffusion of the compound.5 Encapsulation of pharmaceuticals is widely used in the form of microcapsules, diameter from 1 to 1000um; however nowadays scale of encapsulation can be easily reduced to nanometric measures, diameter from 10 to 1000nm. Nanoencapsulation systems are a novel way to deliver compounds in a more specific form as result of controlling the physical properties of the coating of the capsule. Considering this nanoencapsulation can deliver nutraceuticals triggered by a biomolecular mechanism.6 This could lead to the development of a new kind of sophisticated nutrients.

Nanoengineering in the production of nutraceuticals

Main research activities of integrative nanobioengineering aim at combining different disciplines of nanotechnology such as material sciences and microsystems technology with life sciences. This will promote the development of innovative therapies and diagnostic methods.7 The nanotechnology platforms are widely being used to create delivery systems for bioactive natural products and nutraceuticals with the poor water solubility.8

A lot of substances may be used to coat or encapsulate solids liquids, or gases of different types and properties, engineered nanoscale materials may be intentionally added to foods (such as nanoparticle-based delivery systems), or they may inadvertently and their way into foods (such as nanoparticles in packaging materials that leach into the food matrix).9,10 However, regulations for food additives are more rigid than for e.g. pharmaceuticals. Different compounds, widely accepted for drug encapsulation, have not been approved for use in the food industry, because many of these substances have not been certified for food applications as “generally recognized as safe” (GRAS) materials. Actually, the whole food process should be designed in order to meet the safety requirements of governmental agencies such as the European Food Safety Authority (EFSA) or Food and Drug Administration (FDA) in the USA.9 Bio-based encapsulating materials such as polysaccharides (including alginic acid, xanthan gum, chitosan), proteins (albumin, zein, casein, or beta-lactoglobulin), lipids and low molecular surfactants have been widely used as encapsulating materials due to their biodegradability, biocompatibility, and non-toxicity.11,12 Different delivery systems are usually needed to address specific molecular and physicochemical concerns associated with each nutraceutical or functional component.13 The structure of the cell membrane is the most attractive candidate for the fabrication of nanostructured biomaterials.14 Alginate is an anionic polysaccharide of (1–4)-linked b-d-mannuronic acid (M) and a-l-guluronic acid (G) widely used in bioencapsulation of drugs, nutraceuticals, proteins, and cells. Ca-alginate beads represent one of the most widely used carriers for the immobilization of enzymes and proteins as well as for the controlled release of drugs.15 Experimental evidence shows that alginate nanoparticles have been successfully prepared using the emulsification/internal gelation method by creating the ideal conditions for the formulation and have recently been extended to the field of nanotechnology.15 Regulatory scientists working for different legislative frameworks outlined a few crucial information requirements allowing the assessment of the quality and safety of nanotechnology-based products. A selection of such physicochemical parameters including size, stability, and surface properties resulted from this survey. However, for most of the proposed parameters, no standards are available yet, and the reliability and relevance of the analytical methods should be assessed for their use in regulatory testing. Special emphasis should be given to the identification of in vitro tests that have the potential to identify toxic effects triggered by the nano-specific properties of the formulation.16

Nanoencapsulation process

In the encapsulation process, at first, need to know what kind of encapsulate system is suitable for the encapsulation of active compound.17 Encapsulation mainly comprises the entrapment process of deferent biological or chemical cargos with the aim of enabling controlled release under specific circumstances. Indeed, the objective of this case is to shield the bioactive components from the external destructive conditions while permitting minuscule molecules to enter or exit the surrounding membrane.18 Micro/nanocapsule properties may be altered to achieve the best conditions including configuration, mode of release, particle size, ultimate physical architecture and cost.18 Improving oral bioavailability of nutraceuticals has become a promising strategy for enhancing their efficacy in humans. Recently, considerable advances have been achieved in designing and manufacturing engineered nanoparticles to increase the oral bioavailability of nutraceuticals.19 Bioactives can be entrapped in a polymeric matrix in a form of a nanosphere or encapsulated by a protective wall to form a nanocapsule.12 There is a number of techniques available for encapsulation of food compounds. Since encapsulating compounds are very often in a liquid form, many technologies are based on drying. Different techniques like spray drying, spray-bed-drying, fluid-bed coating, spray-chilling, spray-cooling or melt injection are available to encapsulate active agents.9,17 The choice of the adequate encapsulation procedure is a key step once many nutraceuticals are sensitive to heat and to high temperature during the encapsulation process, which could cause loss of their bioactivity.11

Main nano-encapsulation techniques

Engineered nanoparticles can be used to fabricate delivery systems that improve oral bioavailability through a number of mechanisms: increasing nutraceutical stability in foods during the pass through the gastrointestinal tract (GIT); enhancing nutraceutical solubility in intestinal fluids; facilitating nutraceutical absorption by GIT; and decreasing first-pass metabolism in the gut and liver.19 By reducing particle size, nanotechnology can also improve properties such as solubility and efficient absorption through cells.20 The size of the particle that is obtained as a final result will depend on the technique used for its encapsulation; hence, a separation is made, based on the particle size. Particles smaller than 1μm are considered as nanoparticles.15 The following describes some of the most used techniques by the industry in the production of encapsulated products. Spray drying is one the most used techniques, is a unitary operation whereby a liquid product is atomized in a stream of hot gas to instantly obtain a powder. It is appropriate for heat-sensitive materials, since the exposure time at elevated temperatures is short. It is a flexible, continuous, economic technique that produces good quality particles.21 In other instance, spray-chilling techniques are technologies that produce active agents coated with lipids. The material that needs to be encapsulated is mixed with the carrier and atomized using cold air.22 Technologies of fluid-bed coating consist on the solid bioactive components of the food are suspended with a current of air at a specific temperature and sprayed with an atomized cover material (proteins, fats, carbohydrates) in a discontinuous or continuous processor.23 The technique of extrusion consists on producing small drops of the encapsulating material forcing a solution through nozzles or small openings in devices that generate drops. The smaller the internal diameter of the nozzle or openings, the smaller the capsules. It has great advantages for the encapsulation of microorganisms, since it does not involve harmful solvents and can be performed under both aerobic and anaerobic conditions (Akhavan et al., 2018). The molecular inclusion in cyclodextrins and liposomal vesicles is presented as another alternative that provides some specific characteristics to bioactive agents, however, these techniques are more expensive and therefore less studied.21 Liposomes are spherical bilayers which enclose bioactive molecules. The liposomes are formed by dispersion of polar lipids (mostly phospholipids) in an aqueous solution. Encapsulation in cyclodextrins is based on the fact that cyclodextrins can envelop molecular structures by forming molecular inclusion complexes.23

The encapsulation process of emulsification is another technique frequently used with water soluble food active agents.21 It can be defined as a thermodynamically unstable colloidal dispersion consisting of two immiscible liquids, in which one of the liquids is dispersed as small spherical droplets (r<100nm) in the other liquid. There are two types of emulsions: water-oil or oil-water emulsions and water-oil-water double emulsions.11 There are different intervals for particle size reported for nanoemulsions, coinciding in a range of 10-500nm, however, the most appropriate, based on the definition of nanotechnology, are ranges of size smaller than 100nm and having different properties than ordinary emulsions.24 The peculiarity of nanoemulsions, making them prime techniques for nanoparticle engineering, lies in the long-term kinetic stability of their droplet suspension. Nanoemulsions last for months and withstand dilution and moderate temperature changes.8 Ionic gelation was initially developed for the immobilization of cells, alginate is used mainly as a component of the membrane and the combination of divalent ions such as calcium or barium is used to induce gelation. This interaction is a divalent ionic crosslink between the ions of the divalent molecule and the guluronic acid units of alginate, giving rise to a gel known as "egg box model". However, experimental evidence shows that alginate nanoparticles have been successfully prepared using the emulsification/internal gelation method by creating the ideal conditions for the formulation and have recently been extended to the field of nanotechnology.19

The techniques described above (excluding cold spraying and molecular inclusion techniques) mostly use carbohydrates (gums) for the production of capsules and coating materials in food applications. However, these same techniques can be applied using proteins as a coating material.25 Once released into the human gastrointestinal system, the stability of the nanoparticles is largely influenced by pH, proteases, and the presence of other food compounds. Research using natural biodegradable polymers, like proteins, as delivery systems continues to be an area of active research interest, despite the advent of synthetic biodegradable polymers. Proteins possess unique functional properties including their ability to form gels, films and emulsions; offering the possibility of developing delivery systems for both hydrophilic and lipophilic bioactive compounds,26 biodegradability, absence of toxicity and collateral reactions (biocompatible), nutritional advantages and to be recognized as safe in food applications.27 The methods used for encapsulation from proteins are based on processes of precipitation at the isoelectric point, ion pair formation, cross-linking reactions, spray drying, extrusion, enzymatic gelation and gelation by acidification by heat treatment.25 Encapsulation from proteins have been studied for the formation of microcapsules, however, recent research has revealed the development of protein-based emulsion microparticles for the oral administration of lipophilic bioactive compounds. This may provide a new approach for targeted and controlled delivery of nanoencapsulation in the human gut by avoiding nanoparticle aggregation and degradation during storage or in stomach conditions.28

Lipids

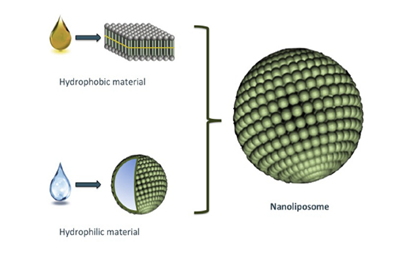

It is possible to find various encapsulation technologies using lipids as a bioactive agent in nutraceutics. In particular, nanoemulsion based delivery systems, which are a promising encapsulation technique, due to the fact that lipophilic bioactive components can be encapsulated within the hydrophobic core of the lipid droplets29 Nanoemulsion have greater stability to gravitational separation and aggregation than conventional emulsion or microemulsions. They provide higher liquid droplet interface area and offer optically transparent systems. Besides, it has a wide application for achieving high encapsulation efficiency, however, nanoemulsions show poor stability in acidic or gastric condition.17 Liposomes are the most used lipid vesicular carriers in the production of nutraceutics, among other vesicular carriers. Liposomes are phospholipid vesicles, composed of a lipid bilayer formed by hydrophilic-hydrophobic interactions that segregate the inner aqueous phase from the external continuous water phase, as shows Figure 1.30 The lipid bilayer acts as a semi-permeable membrane containing hydrophilic head (polar) and a hydrophobic tail (non-polar).17 The most common methods for the production of liposomes are high pressure homogenization, microfluidization, electro-spraying. Besides, liposomes show excellent ability to encapsulate hydrophobic, hydrophilic, and amphiphilic bioactive compounds at the same time. However, several major shortcomings limit their commercial application, like, high cost, low physicochemical stability, drug leakage, and fast release in the gastrointestinal tract.31

Figure 1 Encapsulation of lipid-soluble molecules (hydrophobic), inside the lipid-phase, and water-soluble compounds (hydrophilic), inside the aqueous phase, of a nanoliposome.22

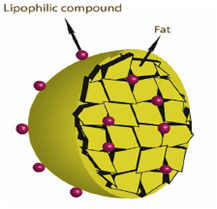

Among the mentioned lipid nanoparticles, SLNs contain lipid droplets that are fully crystallized and have an organized crystalline structure with the bioactive components accommodated within the lipid matrix (Figure 2). SLNs are novel nanoparticulate vehicles developed to overcome the drawbacks of other nanolipid-based carriers, such as nanoliposomes, nanoemulsions, among others.32 Some of the advantages of the employment of SLNs are: high entrapment efficiency, organic solvents are not used in the production methods, low-cost and simple, that is why SLNs represent an option for large scale manufacturing, able to protect the core bioactive compounds (both lipophilic and hydrophilic) against external harsh conditions, finally SLNs can be used in both liquid and solid-state food products.33 Some disadvantages SLNs present are: possible gelation phenomenon, unexpected transitions in fat crystalline structures leading to the expulsion of core materials during storage, assembly and growth of particles, low capacity for the incorporation of bioactives within the nanoparticles.32

Figure 2 Schematic representation of SLNs.32

Carbohydrates

Delivery systems based on polysaccharides are suitable for many industrial applications because they are biocompatible, biodegradable and have a high potential to be modified to achieve the required properties. Carbohydrate based delivery systems can interact with a wide range of bioactive compounds through their functional groups, which makes them versatile carriers that bind and trap a variety of bioactive food ingredients hydrophilic and hydrophobic.17 On the other hand, they are considered as a suitable shell under high temperature processes, due to their temperature stability compared to lipid or protein delivery systems that melt or denature. The main delivery systems based on carbohydrates are: spray drying, coacervation, electro spinning, electroroad, supercritical fluid, emulsion-diffusion, inverted micelles, coalescence of emulsion droplets, evaporation of emulsion solvents, salting, ultrasonication and homogenization high pressure. Below is some of the techniques mentioned above.24

Delivery systems should be designed to protect nutraceuticals during processing, storage and transport from adverse factors such as undesirable interactions with other food ingredients, pH, light, temperature or oxygen.11 The following describes some of the principal factors that can affect the nanoencapsulation:

Emulsions and solvents effect

If techniques need the preparation of emulsions and the use of solvents, it has been observed that the amount of solvents as well as the method used for their evaporation influence the final characteristics of the capsules obtained. When the selected method contains the parameters of emulsion-solvent and evaporation/extraction. The stability of the water-in-oil emulsion is a critical factor for a good internalization of the active principle. When the first emulsion is unstable, the efficiency of the microencapsulation is low because the aqueous phase tends to emerge with the continuous phase of another capsule.34

pH effect

It has been observed that the pH also has an effect on the encapsulation capacity and the final size of the capsules obtained. Studies show that during coacervation process, the sizes of the particles can change if the value of pH changes, since the density is modified of the gel charge (positive, neutral or negative) which gives rise to molecules contracted or expanded as a function of intra molecular repulsion forces (Gonçalves et al; 2018). Also using the technique of ionic gelation, the pH possibly influenced the solubility of the protein, which allowed a better interaction with the polymer, obtaining a higher content of encapsulated hydrolyzate.35

Polymer: concentration and characteristics

Natural starch does not have emulsifying property, and it is mostly hydrophilic, which confines its application for the encapsulation of hydrophobic bioactive compounds. Therefore, modified starches (cross-linked, oxidized, acetylated, hydroxypropylated) are produced by altering the chemical structures through chemical, biochemical, physical and/or enzymatic methods in order to improve functionality and extend commercial applicability.24,36

Temperature effect

An example, the temperature effect on the gelling solution can be controlled to promote heat-set or cold-set gelation of certain biopolymers. This approach can be used to form gelatin hydrogel beads by injecting a hot-gelatin solution into a cold environment. At high temperatures, the gelatin molecules have a random coil conformation, but upon cooling below a critical temperature they form helical regions that act as cross-links between different molecules through hydrogen bonding.37 Conversely, globular proteins (such as those from whey, egg, or soy) can be made to gel by heating them above their thermal denaturation temperature to cause them to unfold and associate through hydrophobic attraction and disulfide bond formation.38,39

Nutraceutical’s applications

Nanoscience and nanotechnology are new frontiers of this century. Their applications to the agriculture and food sector are relatively recent compared with their use in drug delivery and pharmaceuticals. Smart delivery of nutrients, bio separation of proteins, rapid sampling of biological and chemical contaminants and nanoencapsulation of nutraceuticals are some of the emerging topics of nanotechnology for food and agriculture. The nanoscale devices are often manufactured with the view to imitate the nanodevices found in nature and include proteins, DNA, membranes and other natural biomolecules. Nanoparticles can, for instance, be used as bioactive compounds in functional foods.20 The application of nanotechnology in health care is widely accepted as a potential driver of biomedical innovation.16 Nutraceuticals and functional foods have become a multibillion-dollar industry worldwide as people realize their potential to improve health with fewer side effects and less expense than commonly used pharmaceuticals and drugs.40 The term “functional food” sounds more generic, but the history of nutraceuticals/functional foods could be dated back in the late 1960s, for instance, with the findings that polyunsaturated fatty acids could control blood cholesterol level.41-43 The natural products are valuable sources of bioactive compounds, and have been considered the single most successful discovery of modern medicine. In recent years, natural dietary agents have drawn a great deal of attention both from researchers and the general public because of their potential ability to suppress cancers as well as reduce the risk of cancer development.8 Nanotechnology renders hydrophilic substances fat soluble and lipophilic ones water soluble, allowing nanoparticles of some functional ingredients (e.g. carotenoids phytosterols, and antioxidants) to be dispersed in water or fruit drinks to improve their bioavailability.44 Minute micelles (nanocapsules) are used as carriers for essential oils, flavor, antioxidant, coenzyme Q10, and vitamins, minerals, and phytochemicals to improve their bioavailability;45,46 Some examples of the application of nutraceuticals are detailed in the paragraphs bellow. Food industry application of liposomal nanovesicles for the encapsulation and delivery of nutrients and functional ingredients such as proteins, enzymes, flavors, and antimicrobial compounds.47 Encapsulating the nanoparticles of active ingredients (e.g. polyphenols, minerals, and micronutrients) to protect them from oxidation and getting to the taste receptor site, thus to reduce their undesirable off tastes in the finished application.48 Whey protein nanospheres (40nm), which are internalized by cells and degraded therein to release the nutraceutical compounds, can be used as carriers for oral administration of nutraceutical agents to improve their bioavailability. In the food industry, nanotechnology can be utilized to improve food quality, shelf life, safety, cost, and nutritional benefits.10 Patented “Nano drop” delivery systems is in the form of encapsulated materials, such as vitamins. It is administered transmucosally, rather than through conventional delivery systems such as pills, liquids, or capsules; and Chinese Nano tea claimed to improve selenium uptake.

A wide range of nanoneutraceutical products containing Nano cages or Nano clusters that act as delivery vehicles, Nano silver or Nano gold are available as mineral supplements. Carriers including lycopene, beta-carotenes and phytosterols claimed to prevent the accumulation of cholesterol.49 The potential use of the flavonoid quercetin as a nutraceutical, is due to is an excellent antioxidant that also possesses anti-inflammatory, anti-proliferative and gene expression changing capacities.50 Armolipid Plus is a nutraceutical that contains low doses of naturally occurring substances, which exert complementary actions designed to prevent the formation of atherosclerotic plaques. Armolipid Plus offers additional benefits in terms of improvement of vascular stiffness and insulin resistance, which are independent predictors of cardiovascular events.51 The poly (lactic-co-glycolic acid) (PLGA) nanoparticles (NPs) that encapsulate ginsenoside Rg3 and Thioflavin T; has a neuroprotective effect. The PLGA-Rg3 NPs offers an exciting new theranostic material capable of encapsulating natural nutraceuticals for the detection and treatment of AD.52 Further application of astaxanthin in medical field makes it superior to all other nutraceuticals.53 because Can be used as a food supplement.54 has antioxidant activity.55 Has a antidiabetic effect,56 has anticancer activity.57 And also Reduces cardiovascular diseases.58 Nutraceuticals and functional foods are used in the control of plasma cholesterol levels.59 A variety of antioxidant compounds derived from natural products (nutraceuticals) have demonstrated neuroprotective activity in either in vitro or in vivo models of neuronal cell death or neurodegeneration.60 The generation of ROS, either by disabling cellular antioxidants or specific inducers to cause cell death, could be a promising approach for cancer therapeutics. nutraceuticals are a better option because of their safety, efficacy, and ROS-scavenging properties.61,62

Regulatory scientists working for different legislative frameworks outlined a number of crucial information requirements allowing the assessment of the quality and safety of nanotechnology-based products. Food-grade engineered nanoparticles can be utilized to improve the oral bioavailability of nutraceuticals, which may enhance their potential health benefits in humans. Delivery systems must be designed to modulate bioaccessibility, absorption, or transformation profile of nutraceuticals in the GI tract, boosting their bioavailability and consequently, their health benefits. Progress is being made by transferring the knowledge from pharmaceutical applications, including the use of nano delivery systems, absorption enhancers or excipient foods that have been shown to improve solubility, stability or permeability of nutraceuticals. However, there are still some challenges that must be overcome.

None.

Authors declare that there is no conflict of interest.

©2019 Alpizar-Vargas, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.