eISSN: 2577-8307

Mini Review Volume 1 Issue 1

1Department of Biosphere Resources Science, Nagoya University, Japan

2Lida Kogyo Co Ltd, Japan

Correspondence: Satoru Tsuchikawa, Graduate School of Bioagricultural Sciences, Nagoya University, Furo-cho, Chikusa-ku, Nagoya, 464-8601, Japan, Tel 81-52-789-4157, Fax 81-52-789-4157

Received: September 11, 2017 | Published: September 28, 2017

Citation: Sofianto IM, Inagaki T, Itoh M, et al. Stiffness and moisture content prediction model of wooden veneer using fast online near-infrared (NIR) spectroscopic system. Forest Res Eng Int J. 2017;1(2):40-43. DOI: 10.15406/freij.2017.01.00006

The fastest developed online near-infrared (NIR) spectroscopic system with the speed of 120m/min was applied to predict the quality of wooden veneer, i.e., the stiffness (modulus of elasticity/MOE) and the moisture content (MC) from two species, Japanese cedar (Cryptomeria japonica) and Douglas-fir (Pseudotsuga menziesii). The measurement of MOE was conducted by three-point bending test on air-dry MC (12-13%) and the MC measurement was conducted from 30% to 12%. The root mean square error of cross-validation (RMSECV) values from MOE prediction for Japanese cedar veneer and Douglas-fir veneer are 0.9GPa and 1.8GPa, while the RMSECV values from MC prediction are 1.0% and 0.6% for Japanese cedar veneer and Douglas-fir veneer, respectively. This fast speed of online NIR spectra measurement could give better prediction accuracy and be applied in the plywood production industrial line to increase the efficiency.

Keywords: nondestructive measurement, nir spectroscopy, veneer, modulus of elasticity, moisture content

NIR, near-infrared; MAFF, ministry of agriculture, forestry, and fisheries; QC, quality control; MOE, modulus of elasticity; MC, moisture content; SG, specific gravity; S/N, signal-to-noise; LOO, leave-one-out; CV-PLSR, cross-validation partial least square regression; SNV, standard normal variate; MSC, multiplicative scatter correction; SP, smoothing-point; RMSECV, root mean square error for cross-validation; LV, latent variables

Plywood production in Japan plays an important role in providing the materials for wooden building construction. The Japanese Government’s Ministry of Agriculture, Forestry, and Fisheries (MAFF) confirmed in 2015 that the share of domestic wood used for plywood production was rising, reaching approximately 70% in 2014, although plywood was only 30% of the total wood supply. The 186 plywood mills in Japan in 2014 produced 2,18 million m3/year of general plywood.1 Novel technology to increase the productivity on the plywood production line is sorely required.

Near-infrared (NIR) spectroscopy, which has been being widely used in the field of wood science in the last 20 years, seems helpful for increasing the efficiency in the quality control (QC) of the product. NIR spectroscopy, as advanced non-destructive testing technology, shows promising application, as transmitted or reflected spectra of electromagnetic waves ranging from 800 to 2500 nm have been used for the online or on-site measurement of various organic materials, such as agricultural products, foods, polymers, textiles, pharmaceuticals, and petrochemicals.2 Newly developed technology using NIR spectroscopy should be useful to quickly assess the quality of the wooden veneer, i.e., the stiffness (modulus of elasticity/MOE) and the moisture content (MC), without destroying the materials.

Studies on veneer using NIR technology have been done by many researchers. Dry veneer stiffness was predicted using NIR spectra by Fujimoto et al.3 from transverse sections of the logs. Prediction of Yellow poplar (Liriodendron tulipifera) veneer stiffness and bulk density using NIR and multivariate calibration was done by Adedipe et al.4 Koumbi-Mounanga et al.5 Examined the surface quality sensing (MC, surface energy characteristics, and adhesive bond strength) of Trembling aspen (Populus tremuloides Michx.) veneers products by NIR spectroscopy. Carneiro et al.6 Stated that assessment of the flexural static MOE and specific gravity (SG) of veneers is important for quality control and cited it as their reason doing research on NIR and chemo metrics for predicting SG and flexural MOE of Pinus spp. Veneers. Meder et al.7 developed an online NIR spectra measurement system with the speed of 60m/s to predict veneer stiffness from mini-LVL test panels.

This research attempts to use modeling to predict MOE and MC of wooden veneer (Japanese cedar and Douglas-fir) for a real sample using fast developed online NIR spectroscopic system, whose conveyor run at 120m/min, taking into consideration future wood industry application. The prediction model resulting from this research is compared to the previous research.

Materials

In this research, 216 veneers of Japanese cedar (Cryptomeria japonica) with the dimension size of 960mm (L) x 300mm (T) x 3.1mm (R) and 160 veneers of Douglas-fir (Pseudotsuga menziesii) with the dimension size of 1000mm (L) x 300mm (T) x 3.2mm (R) were used for MOE measurement and 10 others veneers of each species were used for MC measurement. All veneers samples were purchased from the plywood factory in Nakatsugawa, Gifu, Japan. All veneers samples were manufactured by rotary cut resulting on tangential surface of the veneer as shown in (Figure 1).

Methods

The gigapascal (GPa) measurement of MOE was conducted by three-point bending test on air-dry MC condition (12-13%) as shown in Figure 2 and the MC measurement was conducted from 30% to 12% with 68 MC values obtained from Japanese cedar veneers and 138 MC values obtained from Douglas-fir veneers (from both each species 10 MC veneers samples). The measurement of online NIR spectra for MOE was conducted after three-point bending test for MOE measurement as well as the measurement of online NIR spectra for MC was conducted after measuring the weight of the MC veneer samples.

The online NIR spectroscopic system was used for the measurements as shown in Figure 3. The NIR spectrophotometer used in this research was constructed by Soma Optics, Ltd. (Tokyo, Japan). An In GaAs linear image sensor with a grating unit (G9211-256S; Hamamatsu Co., Ltd., Hamamatsu, Japan) was employed in this spectrophotometer and six halogen lamps (15W; Hamai Electric Lamp Co., Ltd., Tokyo, Japan) with corrective lenses were circularly arranged as an illuminator unit. The illuminated area was approximately 40mm in diameter for each lamp. The lineal detector sensor was placed at the center of the illuminator unit, and the distance between the sample surface and the detector head was approximately 70mm. The spectrophotometer was mounted on a conveyer belt for online simulation of industry conditions. The online NIR spectra measurement was performed in the wavelength range of 872nm to 1618nm at 1 nm intervals with a 10nm spectral resolution. The exposure time for one scan was fixed at 10 milliseconds and defined based on the need to keep the signal-to-noise (S/N) ratio below 50mm absorbance. The original software controlling the conveyer belt and NIR spectrophotometer were programmed by Visual Studio (Microsoft, Washington, D.C., United States).

The online NIR spectra were obtained from tangential surface of the veneer run in the speed of 120 m/min, regarded as the fastest developed online NIR spectroscopic system for wood industry application together with the same speed as developed by Meder et al.8 though they didn’t apply the device for veneer samples but for lumber. Two areas were scanned in each veneer sample with 10 scans per area. The results from these two areas were then averaged to obtain a single spectral estimate.

The MOE data from three-point bending test and MC data calculated from oven-dry method served as reference values or measured values. Then these reference values were regressed with their correlated online NIR spectra data to construct the prediction model in NIR data analysis. NIR data analysis is also complicated by the overlapping peaks, apart from chemical information physical properties are also reflected in the spectra, while differences between samples result in only small spectral differences. Multivariate data analysis or chemo metrics is used to extract suitable information from the spectra that would correlate with the measured property under investigation; mathematical procedures are used to remove unwanted information without losing important or required information.9 In this research, leave-one-out (LOO) and cross-validation partial least square regression (CV-PLSR) were performed.

Wavelengths from 900-1600nm were selected for the next pre-processing spectra treatment data analysis. Many pre-processing treatments on the spectra such as SNV (standard normal variate), MSC (multiplicative scatter correction), 1st derivative with 25 smoothing-point (SP) (Savitzky-Golay algorithm), 2nd derivative with 25 SP (Savitzky-Golay algorithm), and their combinations were applied. Mean-centering was applied to all spectra while CV-PLSR analysis was being performed. The best pre-processing spectra treatment was determined by the lowest value of the root mean square error for cross-validation (RMSECV) followed by its coefficient of determination for cross-validation (R2CV) and the optimum number of latent variables (LV) obtained from CV-PLSR analysis. MATLAB R2016b (The MathWorks, Inc., Natick, Massachusetts, United States) was used for multivariate data analysis.

Table 1 summarizes the statistical data for MOE and MC. Douglas-fir veneer has higher mean MOE value of 13.7 GPa than 7.4 GPa of Japanese cedar veneer, with wider sample variance around 16 GPa compared to 9 Gpa, respectively. The mean MC for Japanese cedar veneer was 20.0% and 15.0% for Douglas-fir veneer. The range of MC for both Japanese cedar veneer and Douglas-fir veneer is around 17-18%.

Veneer |

Parameter |

N |

Min |

Max |

Mean |

SD |

Japanese cedar |

MOE (GPa) |

216 |

3.2 |

12.5 |

7.4 |

1.29 |

MC (%) |

68 |

12.4 |

30.1 |

20.0 |

5.04 |

|

Douglas-fir |

MOE (GPa) |

160 |

5.6 |

21.7 |

13.7 |

2.65 |

MC (%) |

138 |

11.9 |

29.6 |

15.0 |

3.27 |

Table 1 Statistical data of MOE and MC*.

*N: Number of Sample; SD: Standard Deviation

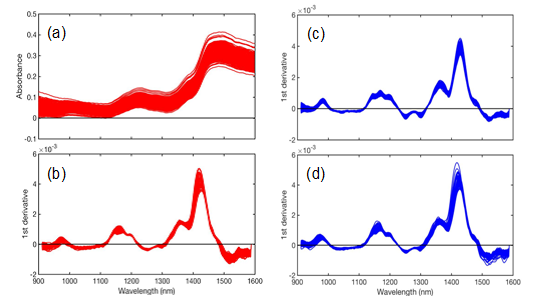

The best MOE and MC prediction models for Japanese cedar veneer resulted from the original spectra and the 1st derivative spectra, respectively. While both the MOE and MC prediction models for Douglas-fir veneer resulted from their 1st derivative spectra. Figure 4 shows the best spectra for MOE and MC prediction for Japanese cedar and Douglas-fir veneer. Spectra obtained from MOE measurement show straight softer shape than more bumpy shape on MC measurement’s spectra. This straight softer shape of spectra were obtained in the same air-dry MC of the veneers samples, while the spectra of MC measurement were measured in various MC between 12-30% of the veneer samples. Such differences showed that NIR measurement is clearly affected by moisture content inside the materials measured.

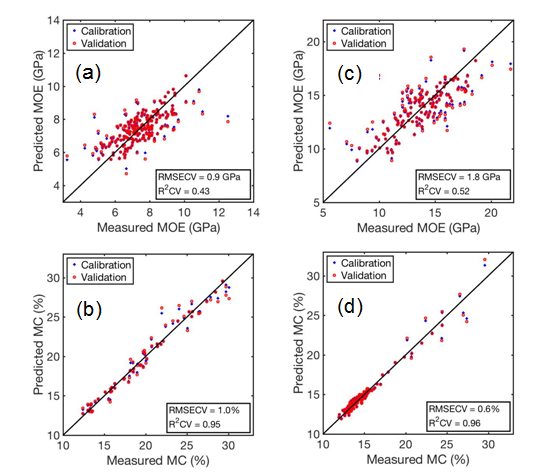

The 120m/min speed of the online NIR spectroscopic system was successfully used to construct the MOE and MC prediction model. Table 2 summarizes the variable data from MOE and MC prediction models for Japanese cedar and Douglas-fir veneer from CV-PLSR analysis. The MC prediction model seems to be giving better prediction accuracy than the MOE prediction model. The RMSECV from MOE prediction obtained for Japanese cedar and Douglas-fir veneer are 0.9 GPa and 1.8 GPa, respectively, on the LVs 6 and 4. The R2CV from MOE prediction from Japanese cedar and Douglas-fir veneer are 0.43 and 0.52, respectively. The RMSECV values from MC prediction are 1.0% for Japanese cedar veneer and 0.6% for Douglas-fir veneer on LVs 4 and 5, respectively. The R2CV values obtained are high with the value of 0.95 for Japanese cedar veneer and 0.96 from Douglas-fir veneer Meder et al.8 Also constructed a gantry that enabled NIR instrument to transverse the length of the cant at a speed of ca. 2m/s or the same speed with this research to predict the stiffness of the Pinus radiata cants. When we compared this research to Meder et al.8 only focusing on the speed not on the samples being used, the R2CV resulted from their research is almost exactly same (0.53) to Douglas-fir veneer’s R2CV, with RMSEP (root mean square error for prediction) value of 1.47 GPa on the optimum number of LV 12 using 411 samples.

Veneer |

Prediction |

LV |

R2CV |

R2C |

RMSECV |

RMSEC |

RPD |

Japanese cedar |

MOE (GPa) |

6 |

0.43 |

0.50 |

0.9 |

0.9 |

1.35 |

MC (%) |

4 |

0.95 |

0.97 |

1.0 |

0.8 |

4.80 |

|

Douglas-fir |

MOE (GPa) |

4 |

0.52 |

0.59 |

1.8 |

1.7 |

1.47 |

MC (%) |

5 |

0.96 |

0.97 |

0.6 |

0.5 |

5.15 |

Table 2 Variable data from MOE and MC prediction model for Japanese cedar and Douglas-fir veneer from CV-PLSR analysis*.

*MOE: Modulus of Elasticity; MC: Moisture Content; LV: Number of Latent Variables; R2C: Coefficient of Determination for Calibration; R2CV: Coefficient of Determination for Cross-Validation; RMSEC: Root Mean Square Error for Calibration; RMSECV: Root Mean Square Error for Cross-Validation; RPD: Ratio of Performance to Deviation

The best RMSECV (lowest) and R2CV (highest) values from the MOE and MC prediction models are also shown on the scatter plots of the measured and predicted of MOE and MC in Figure 5. The online NIR spectra measurement gave lower prediction accuracy compared to the static measurement for veneer stiffness predictions such as done by Fujimoto et al.3 Carneiro et al.6 and Adedipe et al.4 The MC prediction in this research gave better prediction accuracy than MOE prediction comparatively.

We assure that this speed of NIR spectra acquisition is amazing and compatible for wood industry though the R2CV resulted from the very fast speed online system developed like this is still yet acceptable/reasonable. Yet we need to improve the device to give higher value on the coefficient of determination for validation. Before asserting whether this technology is ready or not yet, we shall do many more tests using different species on various wood products for data collection for evaluation of the online NIR spectroscopic system device.

This study examined online NIR spectroscopic system as a novel technology for quick assessment for MOE and MC of veneer materials in plywood industry. The fast speed of 120m/min was successfully run to obtain the online NIR spectra of the veneer. Prediction models for both MOE and MC for Japanese cedar and Douglas-fir veneer were successful constructed with sufficient prediction accuracy. Even though the fast speed of online NIR spectra acquisition has shown satisfactory results for MOE and MC to generate a prediction model for application, more improvements to increase the value of coefficient of determination for validation from this device needs to be done to collect more data for evaluation then convince the wood industry the technology is ready for widespread use.

None.

Authors declare that there is no conflict of interest.

©2017 Sofianto, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.