eISSN: 2577-8307

Review Article Volume 3 Issue 2

Olasgarden Forest & Roads, Sweden

Correspondence: Iwan Wästerlund, Olasgarden Forest & Roads, Solvägen 9, 918 32 Sävar, Sweden

Received: March 19, 2019 | Published: May 14, 2019

Citation: Wästerlund I. Old log houses in Northern Sweden. Forest Res Eng Int J. 2019;3(2):64-71 DOI: 10.15406/freij.2019.03.00079

Log houses from old times are desirable, since those houses have been standing for maybe 200 years, must be of good quality. How many 50- year-old houses are standing today? The problem is to find craftsmen today that know how these houses were built in case of restoration or modernizing these houses. This chapter may clarify some principles with old log houses.

The north part of the globe was covered of km thick ice 15 000 years ago. During warm periods it melted and mammuts, reindeers and mysc were walking around as soon as soon as the ice melted.1 At 7 000 years ago people followed rivers to the inland and archeologic excavations along the Luleå river (one of the bigger rivers in the north of Sweden) found settlements from the stone age at Vuollerim. 1756 the first settlement were recorded in Vuolllerim about 140 km from the coast towards the inland and the mountain area. During 1940 they had 300 inhabitants but during 60-ties and the building of a water power station increased the number of inhabitants to 1 500.2

In the north part of Sweden log houses were easy to make due to the waste forest and were the first types of houses to make when the first ones were to colonise the “empty” part of the country. Just to fell a number of trees with an axe, because the saw was not invented until mid-1800. First look for a suitable cornerstone and place it on the top of a hill.

The timbers were laid on top of each other on cornerstones with mosses in between the logs and varied types of corners were used depending on local tradition. Mostly it was a single room house with a big kitchen that was used for both eating and sleeping with up to 10 children in the house. In my home village one family had 18 children, all with a name that started with an H. 14 survived the 1940-ties with names like Holger, Hendrik, Hugo and Henny.

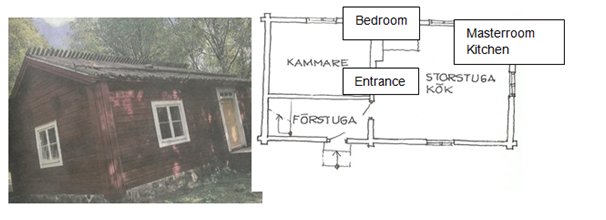

The houses could be built as single room (called so because of mainly just one big room) or pair room (with two big rooms), which the latter ones were mainly as farm houses being quite big for one or two families living in the same house but often without water inside the house. It had to be carried in from the well outside or from a small stream that had been enlarged to let a bucket to be filled. Waste water was mainly just thrown out through the window! (Figure 1)

Figure 1 Example of an old single room house from 1800-ties in north Sweden and the drawing of principle design (Photo Wikner, VK newspaper).

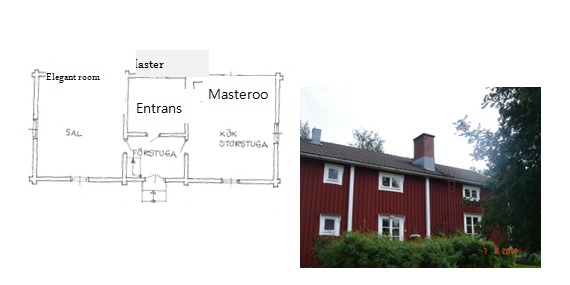

In the so-called pair houses (due to two similar sized big rooms) was more like farm house and below (Figure 2) an example of the design and my own house built 1836 and moved down to the village Sävar 1970 at the coast from Åmsele 150 km north of Sävar, where it was built up piece by piece. It was put on a new basement, which meant it is now with 340m2 in total with 3 floors and design inverted, with 120m2 per floor (Figure 3).3

Figure 2 Example of design of a pairhouse and my own from Holmträsk outside Åmsele now moved to the more coastal village Sävar. Photo I. Wästerlund.

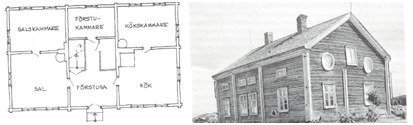

Figure 3 Example of a double cross house which often is a house for at least two families with the new family, often the eldest son with his family, living down stairs and the old family living upstairs. Principle design of the bottom floor to the left.5

Constructions

Outdoor

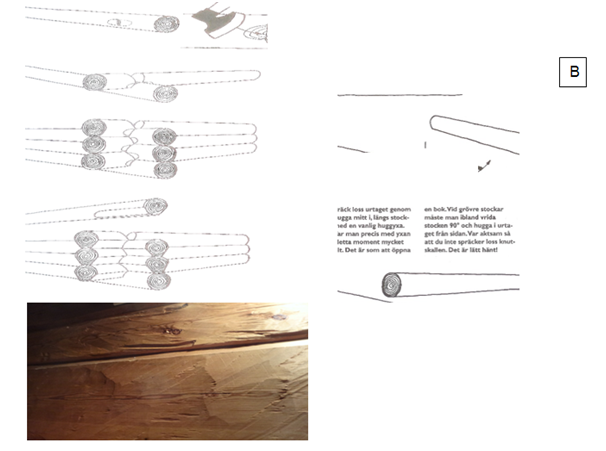

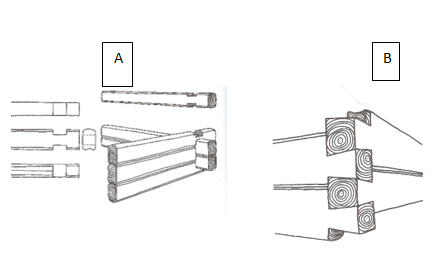

A log house starts with felling a number of trees that has to be debarked to dry out before it can be used. You have to look for trees that are straight and at least 25cm in diameter at breast height. For bigger houses the Dbh have to be at least 6 inches thick with lots of heartwood, which means the trees must be at least 30cm at Dbh. After drying, the stem is made rectangular by trimming with an axe with a special long edge (Figure 4). Then the corners are cut out quite long from the but end because the log ends are vulnerable to rot infections. Best timber is those with a rather big proportion of heartwood, which is easy to find in old pine forest, which is easy to find in northern part of Sweden.

Figure 4 Example on the trimming of the logs by making first the trees in a rectangular shape with a special axe and then continue with cutting for the corners. Here with a simple cutting in one of the logs (After Håkansson, 2004). B. Logs trimmed with the axe to become rectangular in cross section (Photo I. Wästerlund).

Corners are very important because cold could sip in the gaps if not tight pass form and they are also good for the stability of the house. Several types of corners are known, often with a local signum, and are important for both tightening the house and important for the stability. I know a friend who teared down half of an old log house at his summerhouse place because it was rotten, but the rest was still standing and hard to do anything with (Figure 5 & 6).

Figure 5A double cut corner typical (both the upper and below log) are cut in the Dalecarlian area, which increases the stability of the construction. B. During 1800-ties the so-called salmon tail was introduced and the logs were not pointed out but the log end were pointing inwards and locked with a with a small rod (dowel) going between the logs. Often a panel was put outside the wall to cover to cover the vulnerable log ends.3

Figure 6 Grooves are made in each of the togs under side for putting in isolation material to make the wall warmer, but the edges around the groove must be of good quality to avoid cracking of the wall, since the whole weight is resting on that sides.3

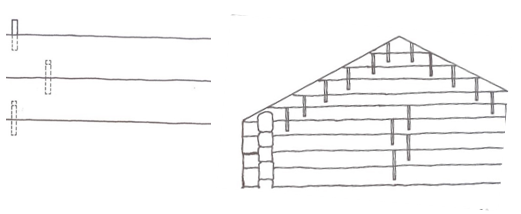

Stones are easy to find in northern Sweden, but the stones should have a proper flat surface, to put the first logs on (Figure 7). Then was just to pile up the other logs on top. But before, the logs must be trimmed with a groove on the down side of the log, in old times mosses were used. Sphagnum mosses should not be used because they are hygroscopic. Better to use Pleurozium or Hylocomium splendens, which are named after their use in Swedish. The mosses are rolled to a Swiss roll after taking away twigs or needles which can create an opening in the roll.4

Figure 7 Corner stone to both lift up the bottom logs from the soil and to have a good anchoring for the house. In old times only two types of axes were used and for the simple houses and one with a long edge.4

The first logs are put in the same direction but later on every second log are turned with the top end towards the butt end of the log below to give a rather straight wall of the house.

To secure the logs often wooden rods (dowels) ca 10- 15cm put between the long in predrilled holes, usually about 3 cm in diameter. In old times this was done by hand with a special formed hand drill (auger). The dowels should be of the same type as the logs to secure that the wood shrink the same way as the log during dryer periods. With fibre direction going in skewed way around the log it could be a tough job to drill the holes but necessary to do for the top logs (Figure 8).To secure the logs lying on top, the dowels were used (Figure 8). A tight wall with 6 inch thick timber could actually be quite warm but when outdoor temperature goes up, the inside could get cold from the cold temperature stored in the timber.5

Figure 8 Example on the use of short rods (dowels) used to secure the position and C the logs should have a groove out along the stem that could be filled with mosses to tighten the walls.3

Next step is to put a roof on the house and it could consist of one top beam for a single room house running from one gable to the other side being at least 5 m long and proper diameter to hold for roof material and 1 m of snow. Sounds quite light but rain and some melting of the snow could mean a weigth more than 400kg per m3 during springtime. The first roof material were birch bark stretched out (thus from thin and midsized trees – thinner bark) that was hold in place by thin logs a cross the roof. Later in 1800-ties the bark was replaced with roofing shingels from splinted knot free wood and was nailed with some overlapping. In modern houses the shingels (lasting about 50 years) are replaced by roofing tiles because the shingels. It is interesting that hand splited shingels have a much longer lasting compared to mechanical carving, since the hand carved shingels followed the cells better (Figure 9).

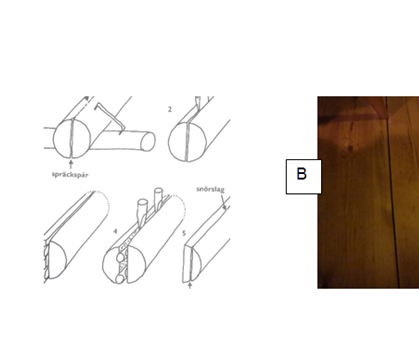

For planks to the floor, an axe and wedges to crack out planks were used, to make a decent straight floor with 20-30cm wide planks se below (Figure 10). The underside was trimmed to fit the floor beams often without any edge trimming of the planks and to give a horizontal floor.

Figure 10 How to crack out the planks without using a saw (After Håkansson, 2004). B. By using a plane the planks could get a smooth off surface, here after a modern planer and sandpaper and varnish (Photo I. Wästerlund).

Nowadays building is much easier when a chainsaw is available and that one came with the 1940-ties. Tongues on the planks that were shaved out to make it easier to tighten the planks.

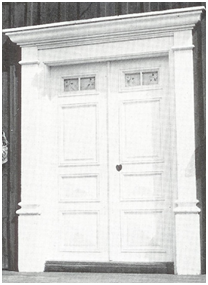

Next step is to make place for the door, often by inserting a plank with a tongue into the vertical groove to hold the timber in the wall straight. Single room houses had usually one door but pair houses used double doors but only 0.7m wide each and a light above the doors (Figure 11), often decorated, because it was the front part of the house. Today there might be needed with extra doors inside to give a warmer entrance of the house and then the outer doors must go outwards and the inner doors inwards. Several different various types are known, often with local impression.

Figure 11 Example on a double door of a pair house with a light above the door. Common on pair houses.6

Already from mid-1600 Falu red paint was used to paint the houses,6 which came from the copper mine in the city Falun. At beginning of 1700 a man was found in the copper mine and after 20 years he was found in the mine and very well preserved. They started to study why he was so well preserved and they found out he was conserved thanks to iron ochre , which is a red slam colour mixed with rye meal and linseed oil, and together with tar (Sixtensson & Lidström, 1984), these two colours became the characterization picture of the landscape, and preserved the outside of the houses.7

Indoor constructions

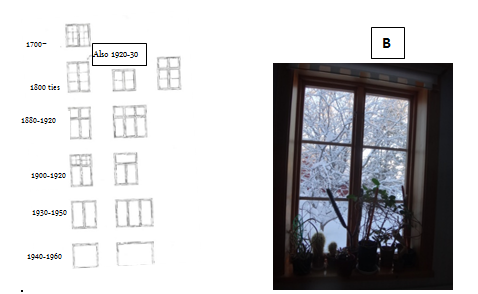

Windows must be put in to give some light in the house. The window glass was mouth blown up to 1920, when windows were made industrially and the windows could be made bigger (Figure 12).

Figure 12 Window types during 1700 and 1960 (after Sixtensson & Lidström, 1984) and B. A more modern construction from 1970, looking quite old in design and being 1.6 m high.(Photo I Wästerlund).

For both cooking, light during wintertime and warmth an open fire place was installed in one of the corners in the house with strong flooring because the construction is heavy. This construction served its purpose but from energy point of view not a good solution. The middle iron support was often supplied with a rod of metal for cooking, just to swing in when the warmth was needed (Figure13B & 13C).

A milk cabinet is often standing in the entrance hall with flat wooden bowls to fill with milk to let the cream to float up and be collected for the echurn and then make butter for the household with an echurn (Figure 13A & 14).

Figure 13 A A milk cabinet with B. Milk bowls to collect cream floating up from the milk and C. Echurn for making butter. (Photo i. Wästerlund).

Figure 14 An old type of cabinet bed. A complex bed with a cabinet inbuilt and drawer, but usually the bed was covered with curtains. This was the master bed for the old man who wished to have control (old place in Lycksele, Kerstin Westin, painting).

Celling, scheme

The celling was often made with overlapping planks or boards inserted in the beams. This type of celling is called schesme. It could be painted in white, or the celling was covered with a sheet of paper or paperboard (at the end of 1800) (Figure 15).

Figure 15 Traditional celling with overlapping boards inserted in a groove in the celling beam (Photo I. Wästerlund).

Outside the house

Since there were no toilet room in the house, the people had to build an outdoor toilet, which often was connected to the barn. Usually it was a wooden bench with a hole to let out the excrements. In my home village, two brothers were somewhat wild. One brother was going to make some fun to the other one and greased the sides of the hole with spruce resin and waited hidden behind the barn. But unexpectedly their sister had to go to the toilet and was sitting and reading a ladies magazine. Thus the resin melted. 10 minutes later she had done her business and went up yelling loudly. The two boys did not get a dinner that afternoon (Figure 16 & 17).

None.

Author declares that there is no conflict of interest.

©2019 Wästerlund. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.