eISSN: 2577-8307

Research Note Volume 3 Issue 3

Debre Birhan University, Ethiopia

Correspondence:

Received: July 06, 2019 | Published: August 30, 2019

Citation: Taddese G. Effect of polymaleic acid on saline sodic soils. Forest Res Eng Int J. 2019;3(3):83-86. DOI: 10.15406/freij.2019.03.00082

Saline-sodic soils in Middle Awash Valley area of Ethiopia have very high soluble sodium content and exchangeable sodium percentage (ESP). Leaching soluble salts with water alone could not fasten reclamation of these soils. Because all pore spaces of the soil were already sealed off with precipitated soluble salts; which retarded percolation of leaching water to the soil. Hence, Polymaleic acid was tested under controlled pot leaching under laboratory condition. The treatments were control (leaching with water only), 10, 20, 30 and 40ml polymaleic acid per kilogram of soil. Each treatment was replicated four times. As a result of leaching and polymaleic acid application to the saline - sodic soil, the ECe of the soil was was drastically reduced as the rate of polymaleic acid rate was increased. At the end of leaching, soluble cation and anions were also drastically decreased as compared to the control treatment. Hence, polymaleic acid soil conditioner could be used as an amendment for reclamation of high saline - sodic soils.

Keywords: leaching, permeability, polymaleic acid, sodic – soil, pore-volume, soluble salts

Over thirty percent once productive agricultural land in the Middle Awash Valley was abandoned due to increasing soil salinity. These salt - affected soils have excessive soluble salts in their upper soil layer, which restrict normal plant growth. So far reclamation of saline - sodic soils was carried only under controlled column leaching with the application of calcium chloride and gypsum.1 In order to control the shallow saline ground water, subsurface drainage system was installed, and, currently salt leaching is proceeding on a large scale. However, in spite of all the salt leaching, the soil still appeared to be less aggregated. In recent years, successful efforts have been made in using organic polymers for reclamation of saline-sodic soils.2 These polymers could improve soil porosity and aeration.3,4 Active groups of the macromolecules or polymers can be absorbed into the crystalline layers of clay domains and so the flexible chain of the molecule binds as bridge to many of clay particles or domains.5 At present, more focus is paid on polymaleic acid than traditional amendments and other organic polymers. Polymaleic acid increases solubility of calcium and magnesium salts.6 Once these Ca and Mg minerals (i.e. Ca2+ and Mg2+) are freed they can exchange places with the sodium (Na+) on soil particles and the excess of sodium salts then can be leached below the root zone by either rainfall or irrigation water,7,8 Soil compaction can be reduced by the replacement of Na+ with Ca2+ and Mg2+ on soil particles. Well-flocculated soils have greater pore space between particles, allowing air and water to move freely throughout the soil profile. Hence, the objective of this work was to see the influence of polymaleic acid on salt leaching.

The experiment was conducted under laboratory condition. The poly pots with base 6.5; 10cm top inside diameter and with 10.5cm height were used for leaching. Alluvial saline – sodic (270dS.m-1), silty clay loam textured soil with 1.59gcm-3 bulk density was passed through 2.0mm sieve size. The amount of leaching water was calculated based on pore volume. Pore volume of the soil is simply volume of air and water of the soil. Pore volume was calculated from the following relationship,10 Equation 1:

(1)

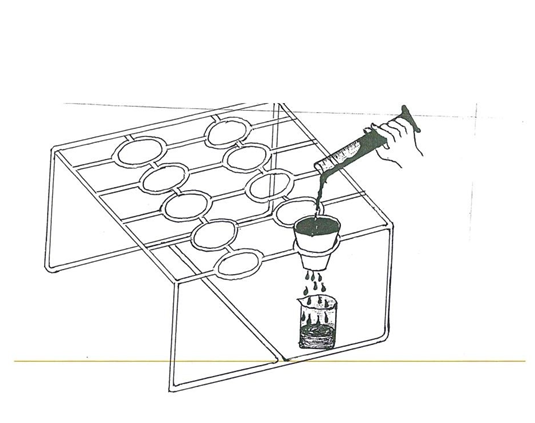

Where; PV=Pore volume; Dw=depth of water needed for reclamation in excess of any soil moisture depletion (m); Ds=depth of soil to be reclaimed (m) K (coefficient)=(C/Co). (Dw/Ds) (2); C/Co is the relationship between the fraction of the initial salt concentration (ECe) remaining through the profile per unit depth of soil. The K = coefficient, for silty clay loam textured soils was 1.19. The soil was packed by gentle and constant tapping until the weight reached one kilogram. Prior to soil packing the porous base of the pot was sealed with Whatman No 42 filter paper to minimize soil loss through porous base of the poly pot during the application of leaching water. Polymeric acid(Spersal) of 30% concentration was used. Spersal is a registered trade mark of FMC/Sotac Corporation produced as a soil conditioner.6 BASF Company in Ethiopia donated the experimental sample to the soil section of Melka Werer Agricultural Research Center. The treatments were control or leaching with water only, 10ml, 20ml, 30ml and 40ml polymaleic acid, replicated 4 times. Prior to the application of polymaleic acid to the soil, all pots were brought to constant moisture level (43% moisture on dry soil basis). Polymaleic acid solution was also considered in the soil moisture. The saturated leaching was conducted by maintaining a constant 2cm head of surface water. Soil section staff of Melka Werer Agricultural Research Center (Figures 1 & 2) designed the leaching block.

Figure 1 Leaching block at Melik water Agricultural research center.16

Distilled water (ECw less than 4.0micromhos cm-1) was used for leaching. Leachate was collected in volumetric flasks at nearly fixed time intervals (for 20minutes). Leaching was conducted in room with no temperature control mechanisms so that there could be a wide temperature fluctuation. Leachates were analyzed for pHw, ECsw and constituents of the major cations and anions. After leaching the soil in the pot was analyzed for exchangeable and soluble cations. All chemical analyses were carried by the procedure set in Handbook No.60.11

Electrical Conductivity (EC) and pH

The electrical conductivity of the leachate was decreased as a function of pore volume (Table 1).

Trea |

Pore Volume |

||||

0.5 |

1.4 |

1.8 |

2 |

2.4 |

|

Control |

641.4 |

373.6 |

11.3 |

9.3 |

7.4 |

10ml PMA |

521.8 |

268.8 |

5.8 |

2.7 |

5 |

20Ml PMA |

449.3 |

289.6 |

6.1 |

2.7 |

6.3 |

30ml PMA |

449.9 |

176.6 |

15.9 |

2.8 |

3.5 |

40ml PMA |

531.5 |

313 |

19.1 |

4.2 |

3.2 |

Table 1 Electrical conductivity (dS m-1) of the leachate as function of Pore Volume

NB: PMA = Polymaleic acid

The Results showed that EC varied significantly with Pore Volume (Table 2). On the other hand, more reduction of EC of the leachate at the end of leaching was obtained from application of polymaleic acid as compared with control. Particularly, application of 30 and 40ml polymaleic acid kg-1 of soil showed pronounced reduction in electrical conductivity of the leachate at 2.38 pore volume.

Source |

|

|

Type III Sum of Squares |

df |

Mean Square |

|

F |

|

Sig. |

Intercept |

Hypothesis |

279545.6 |

1 |

279545.6 |

5.187 |

0.062 |

|||

Error |

329007.6 |

6.104 |

53898.191a |

||||||

Treatment |

Hypothesis |

21234.48 |

1 |

21234.483 |

1.649 |

0.215 |

|||

Error |

244682.1 |

19 |

12878.008b |

||||||

Trea*PV |

Hypothesis |

953956.1 |

4 |

238489.017 |

18.519 |

0 |

|||

|

Error |

|

244682.1 |

19 |

12878.008b |

|

|

|

|

Table 2 Tests of Between-Subjects Effects Dependent Variable: EC

a.182 MS(PV) + .818 MS(Error)

b (Error)

The pH of the leachate was also decreased at application of 40ml polymaleic acid and showed statistically significant difference (Table 3 & 4).

Treatment |

Pore Volume |

|

|

|

|

0.5 |

1.4 |

1.8 |

2 |

2.4 |

|

Control |

7.3 |

7.6 |

8.2 |

8.2 |

8.7 |

10ml PMA |

7.4 |

7.9 |

7.8 |

7.7 |

7.1 |

20Ml PMA |

7.5 |

8 |

7.6 |

7.5 |

7.2 |

30ml PMA |

7.5 |

7.9 |

6.9 |

6.9 |

7.4 |

40ml PMA |

7.4 |

7.9 |

5.9 |

6.2 |

6.5 |

Table 3 pHsw of the leachate

Source |

|

Type III Sum of Squares |

df |

Mean Square |

F |

Sig. |

Intercept |

Hypothesis |

1352.768 |

1 |

1352.768 |

2159.592 |

0 |

Error |

2.506 |

4 |

.626a |

|||

Treatment |

Hypothesis |

2.294 |

4 |

0.573 |

4.243 |

0.016 |

Error |

2.162 |

16 |

.135b |

|||

Treatment |

Hypothesis |

2.506 |

4 |

0.626 |

4.635 |

0.011 |

Error |

2.162 |

16 |

.135b |

|||

Trea * Pore Volume |

Hypothesis |

2.162 |

16 |

0.135 |

. |

. |

|

Error |

0 |

0 |

.c |

|

|

Table 4 Tests of Between-Subjects Effects (Dependent Variable: pH

a MS(PV)

b MS(Trea * PV)

c S(Error)

Leaching with water (control) also showed good performance in removing soluble salts from saline - sodic soils. Polymaleic acid increases solubility of Ca2+ and Mg2+,6,12 that can exchange Na+ from exchangeable site of the soil. Moreover, very high concentration of soluble Na+ and Ca2+ + Mg2+ was leached out in accordance with polymaleic acid rate (Table 2). Similar data was obtained by Gebreselassie,1 and Nawar.2 They both came to conclusions that use of chemical amendment could improve solubility of salts. Considerable reduction in soil salinity was observed after leaching as compared to the initial soil salinity level. However, application of polymaleic acid drastically decreased the salinity level of the soil as compared to that of the control treatment (leaching without polymaleic acid). More reduction of salinity in the soil was obtained also at application of 30 and 40ml polymaleic acid to the soil than the rest of the treatments (Table 5).

|

|

Pore Volume |

||||

Treatment |

Element |

0.48 |

1.44 |

1.75 |

1.98 |

2.32 |

|

|

(decimol + or -).kg-1 |

||||

Control |

Na |

378.9 |

255.2 |

52.9 |

6.0 |

5.4 |

K |

10.3 |

5.8 |

1.1 |

0.5 |

0.8 |

|

Ca |

22.0 |

23.5 |

2.5 |

2.2 |

6.6 |

|

Mg |

75.8 |

39.0 |

8.0 |

2.2 |

2.2 |

|

HCO3 |

2.3 |

10.5 |

1.2 |

1.2 |

1.8 |

|

Cl- |

418.3 |

272.5 |

12.5 |

5.1 |

0.9 |

|

10ml PMA |

Na |

416.1 |

400.7 |

33.3 |

4.1 |

5.3 |

K |

8.6 |

4.7 |

4.4 |

0.1 |

0.2 |

|

Ca |

28.6 |

11.1 |

4.0 |

2.5 |

5.4 |

|

Mg |

57.2 |

38.0 |

8.5 |

0.8 |

1.8 |

|

HCO3 |

2.1 |

7.5 |

5.5 |

1.2 |

1.9 |

|

Cl- |

395.5 |

207.5 |

20.0 |

9.3 |

4.9 |

|

20ml PMA |

Na |

405.9 |

236.6 |

21.4 |

2.4 |

4.8 |

K |

8.1 |

5.5 |

0.3 |

0.1 |

0.1 |

|

Ca |

28.5 |

14.5 |

2.5 |

1.7 |

5.1 |

|

Mg |

45.6 |

28.0 |

6.0 |

1.2 |

1.4 |

|

HCO3 |

2.4 |

12.0 |

12.0 |

1.8 |

3.9 |

|

Cl- |

372.5 |

232.5 |

12.5 |

7.6 |

1.5 |

|

30ml PMA |

Na |

396.4 |

192.4 |

54.6 |

1.3 |

2.8 |

K |

8.8 |

4.6 |

1.1 |

0.2 |

0.2 |

|

Ca |

19.0 |

20.4 |

20.9 |

1.5 |

4.4 |

|

Mg |

45.6 |

28.0 |

6.0 |

1.2 |

1.4 |

|

HCO3 |

2.4 |

12.0 |

12.0 |

1.8 |

3.9 |

|

Cl- |

418.3 |

207.5 |

15 |

7.3 |

0.7 |

|

40ml PMA |

Na |

423.9 |

237.6 |

60.9 |

3.7 |

2.7 |

K |

10.0 |

4.7 |

0.9 |

0.2 |

0.3 |

|

Ca |

19.4 |

4.4 |

13.0 |

2.5 |

1.8 |

|

Mg |

61.2 |

34.5 |

18.0 |

1.2 |

1.1 |

|

HCO3 |

3.6 |

9.5 |

25.0 |

3.6 |

3.2 |

|

|

Cl- |

139.5 |

255.0 |

20.0 |

9.1 |

6.7 |

Table 5 Soluble cations and anions concentration (decimol + or - Kg-1) of the leachate as a function of pore volume and polymaleic acid rate

NB: PMA=polymaleic acid

Saline - sodic soils have very high soluble Na+ and ESP.7,8 As a result of polymaleic acid application and leaching, soluble Na+ and Ca2+ + Mg2+ were remarkably reduced from the very high saline - sodic soils (Table 5). The reduction of soluble Na+ and Ca2+ + Mg2+ in the reclaimed saline - sodic soil was more as the applied rate of polymaleic acid was increased. Several authors,3–5,13,14 indicated that, synthetic soil conditioners could improve soil aggregation, aeration, and soil water relationships of the soil. Lastly, polymaleic acid as soil conditioner could be used as chemical amendment in the reclamation of saline - sodic soils.

Application of polymaleic acid soil conditioner on highly saline - sodic soil substantially reduced both salinity and sodicity of the soil. Apart from that, if an economic constraint arises from polymaleic acid use for the reclamation of saline - sodic soils, leaching with water could also be used successfully.15–17 Finally, polymaleic acid could be used as an amendment for reclamation of saline - sodic soils.

None.

None.

Author declares that there is no conflict of interest.

©2019 Taddese. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.