Advances in

eISSN: 2572-8490

Mini Review Volume 10 Issue 1

Professor of Clinical Pathology, Chair Stem Cell, Regenerative Medicine, Nanotechnology and Tissue Engineering (SRNT) Research Group, Faculty of Medicine, Menoufia University, Egypt

Correspondence: Professor of Clinical Pathology, Chair Stem Cell, Regenerative Medicine, Nanotechnology and Tissue Engineering (SRNT) Research Group, Faculty of Medicine, Menoufia University, Egypt

Received: February 02, 2024 | Published: February 21, 2024

Citation: Montaser LM. In situ 3D printing of stem cell in regenerative medicine takes future center stage. Adv Tissue Eng Regen Med. 2024;10(1):14-18. DOI: 10.15406/atroa.2024.10.00147

There are many services 3D printing (3DP) supplies for the medical domain with a view to ameliorate and keep patients' lifetimes. 3DP in medicine has authorized customization, prototyping, industrialization, and study. The regions of implementation include surgical elaboration, prostheses, dental, 3DP of tissues and organs, medicament doses and pharmacology, and makings of medical agents and instruments. 3DP technology is conceivable utilized for manufacturing exact copies of human anatomic matters, moving a worthy function in pathology education, veterinary anatomy schooling, zoological models cloning, duplication of scarce museum samples, and printing of stem cell and tissue facts from confocal microscopic examinations. 3DP technology can be applied to surrogate human organ transplants and to make patient-definite organ duplicates that surgeons can be utilized to exercise on before implementing complex surgeries. In this paper according to Laila M. Montaser deep expertise in liver tissue engineering, might be a prospective futurity settlement to scalability of the liver transplant which may alleviate the troubles linked with the organ lack, may recovery liver failures and may outputs skillfully functional organ to be planted or applied as an instrument located out the body, as a pragmatic pattern for medicament checking, beside for the investigation of pathological diseases such as liver cancer and cirrhosis. This was the abstract of Montaser keynote invited speech which was recorded and submitted to the 3DP Conference and Expo 2020, Nov 18-20, Seoul, Korea entitled “Application of 3D printing in Regenerative Medicine”. This symposium was sponsored by the 3DP Conference and Expo Seoul - A new era of advanced manufacturing. The first day of the conference, November 18, was held as an in-person seminar in Seoul (KINTEX), Korea whereas the second day of the conference, November 19, was an on-line (recorded) seminar without gathering onsite. Her pre-recorded presentation (PowerPoint slides with her recorded voice) was broadcasted on the second day of the conference with Korean translation. This manuscript shows Montaser future vision possible bio Nanomaterial scaffolds fabricated by the two most widely used techniques, namely, electrospinning and 3DP of future directions for in situ 3D bioprinting. The aim of this paper is to highlight the attention given by a feminist scientist to in situ 3DP technology literacy of stem cells as a new, innovative and revolutionary technique.

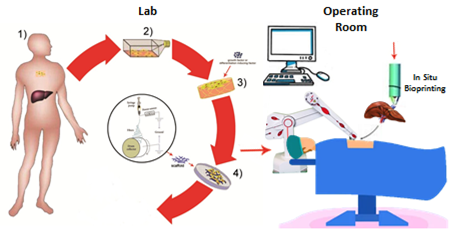

Tissue faults out coming from illness, injury, or surgical amputation request therapy to retrieve tissue construct and job. There are defined defiance's joined to rebuilding multiplex tissue faults.1,2 Per se disorders are hard to cure utilizing formal and principle measure transplants. Indefinite, they want to be cured by utilizing converted or arranged transplants or structures. The enforcement of 3D bio-printing of tissues employing stem cells in association with the elaboration of laboratory level 3D scaffolds centering mainly, on the two more broadly utilized methods, electro-spinning and 3D printing provides the prospect to supply builds that can be preplanned to accurately proper flaw measure and form. Those structures are as a rule layout and simulated outside the body and then instilled in vivo.3 Diagrammatic of future directions for in situ 3D bioprinting is imagined in Figure 1.

Figure 1 Diagram outlining the robot-assisted in vivo 3D bio-printing in the frame of minimally invasive surgery, left part in the lab shows the differentiation of stem cell with application of electrospinning technique, while the right part in the operating room displays the intraoperative surgery with 3D Printing enforcement.

Stem cells are cells with the prospective for itself-renovation and much discrimination. Induced pluripotent stem (IPS) cells are charming in regenerative medicine. In 2006, amidst the preface of four tools, Yamanaka and Takahashi successfully created IPS cells from mouse fibroblast cultivation.4 Recently, IPS cell investigations have achieved major advances in organoids progression,5 medication detection,6 illness mechanization research,7 and sickness therapy.8

Due to passage incidents, injuries, burns, inborn disfigurations and other causes, a great number of sicknesses with tissue or organ disorders require a demanding remedy each year. The lack of granters, transplantation refusal and other issues give rise to an insufficient fitting for organ and tissue change, reform and regeneration of sick persons, so regenerative medicine derives inside the entity. Stem cell treatment performs an honorable service in the scope of regenerative medicine; however it is hard to block big tissue faults by injection alone. The researchers fuse 3D printed bone tissue engineering scaffoldings with stem cells to realize the wanted result. Those scaffoldings can imitate the extracellular matrix (ECM), bone and cartilage, and in the end compose useful tissues or organs by supplying constructional help and encouraging linking, generation and discrimination.9

3DP technology, also named material flowing printing10 or inkjet printing11 is an additive manufacturing technique that makes builds by selectively sticking polymer or inorganic powders into 3D forms strata by strata.

3DP displays top curative impact12 and widely optimized material features13 in clinical implementation. The scientists have also found that quadrant-formed scaffoldings foster the prosperity of further human mesenchymal stem cell outgrowth and chondrogenic discernment contrasted with rigid or hexagonal spongy scaffoldings.14 It fabricates 3DP, especially proper for the manufacture of constructs for bone tissue restoration, not to remember the inducement of guided discrimination and propagation of stem cells.15

3DP technology can print extremely correct and compound interior and exterior constructions that modify to mechanistic and biotic superficial distinctive,16 so authorizing the elaboration of customized, malady-specified transplants that are very much appropriate for tissue and organ disorders, beside illness emulation podiums17 and stem cell study stages.18

Ashammakhi and colleagues19 stated that, ideally, an amended 3D printed transplant should be fabricated and obtained through the identical place. However, that prospect has been trapped by a diversity of technical, workable, and regulatory issues, and thus a long road. That idealistic resolution would harness a usually utilized 3D printing manner in the operating room and 3D print builds in situ. This motif may require the employ of either handheld printers20–23 or robotic arms loading printer cocks, that are planned by computers and scanners that always amount to the correct extent of the trouble.24

Mabrouk and team25 explained that considerable progress has been made in the domain of tissue engineering (TE), essentially in the composition of 3D scaffoldings for exchanging injured tissues and organs in lab circumstances. Though, the holes in information in utilizing those methods in preclinical experiments and behind and, in specific, in functional scripts (e.g., replacing true structure organs) have not been examined widely in the occurring literature. Besides, it is noticed in the literature that whilst novel manners for the installation of 3D TE scaffolding have been sophisticated, several of the too early styles are yet being employed. Only wants to be conscious of the cause, whether few, beyond the notability of conventional electrospinning way above new progresses in 3DP mode for the fabrication of 3D scaffoldings presented the prestige of the previous on top of the last, specified by the number of leaflets in the expert zones. Electrospinning technicality is of attention to the manufacture of 3D scaffoldings due to its tunable parameters and, so, it has matured rapidly in together manufacturing and biomedical realms. Moreover, 3DP owns a slothful development average while it is contrasted to the electrospinning mechanism despite it being a convoluted procedure with various engineering agents with no esteem to the biological processes. Consequently, in the present periods, extreme progression was investigated to promote the 3D printer method in a harmonious pattern with tissue and organ cases. Hence, jointly electrospinning and 3DP technicalities are leading the paths for researchers to improve 3D-styles with innovative procedures using a varied domain of biomaterials that is presently their central spot of study efforts in the area of tissue engineering.

When 3DP is contrasted to the electrospinning technique, it is a convoluted operation with various engineering agents with no regard to the biological frameworks. For that reason, in the current days, a lot of progress was deemed to evolve the 3D printer organization in a proper style with tissue and organ circumstances. As a consequence, jointly electrospinning and 3DP technologies are directing the tactics researchers to establish 3D-builds with cut edge processes employing a several areas of biomaterials that is presently their centric spot of research attempts in the realm of TE.

The story of Montaser with 3DP started in Seoul, Korea Conference since the first few days of 2020 resulted in a series of publications twice in peer-reviewed international journals and fourteen global webinars, besides, reviewing and judging many papers and three book chapters by now.

Laila M. Montaser was reviewing and judging26 a Book Chapter entitled "Study of Biomaterials and Bio-printing" in a Book Name: "Advanced Concepts in Pharmaceutical Research" for B P International (an International publishing organization that publishes high quality books in scientific, technical, and medical areas), when she received an email about the nomination for global award for 2024 TCT Women in 3DP Innovator Award. This award characterizes women who are at the top of their career, driving the responsibility in evolving, promoting and innovating within the 3DP and additive manufacturing globe. She is proud to cooperate with Women in 3DP for this world-class appreciation. So she has inspired and emphasized to write this paper highlighting the story from the start behind this email. Later on, on 13 Dec 2023 Prof. Montaser awarded a Certificate of Excellence in International Peer Reviewing of that interesting chapter - Certificate No: BPI/PR/Cert/_6880B/PRO (Figure 2).

Figure 2 A certificate of Excellence in International Peer Reviewing dated 13 Dec 2023 - Certificate No: BPI/PR/Cert/_6880B/PRO in revision & judgment of a Book Chapter entitled "Study of Biomaterials and Bioprinting" in a Book Name: "Advanced Concepts in Pharmaceutical Research" for B P International.

At the beginning of 2020, Montaser received an invitation letter as a world-class speaker to deliver a keynote show at the international conference on Inside 3DP conf. 2020, Nov 18-20, Seoul, Korea. After her approval, they asked to send an abstract of her keynote presentation and also a session summary in the medical track to be published with her picture on the conference website. They announced World Class Invited Keynote Speaker Prof. Laila Montaser (Figure 3) and also the abstract of her talk on social media (Figure 4). But the conference was held in a hybrid fashion due to the inconvenience of traveling abroad caused by COVID-19. She was required to submit a recorded presentation video file (in English, 30-min-long). Their team added Korean subtitles to the video and distributed them to all registered delegates.27

Figure 3 Announcement of Prof. Laila Montaser World Class Invited Speaker in the social media at Inside 3D printing conf. 2020, Nov 18-20, Seoul, Korea.

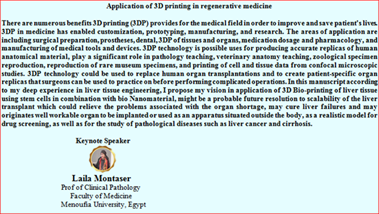

Figure 4 Announcement of the abstract presented by Keynote speaker Laila Montaser in the social media at Inside 3D printing conf. 2020, Nov 18-20, Seoul, Korea.

Laila M. Montaser28 reported in the brief summary of her invited speech which was sent to Global TIPE 3DP conference 2023, Jan 24-26, virtual organized by Women in 3DP (located in New York City, NY, USA) entitled "The Latest Technology in 3D Bioprinting", the target of these talks was to give insight, best practices, or strategic information to the audience. The author explained that contemporary technology is incapable of fabricating emulated tissue-engineered buildings with the equalization of the plain tissue. The modern development of 3DP technology permits the induction of tissue replacements integrating cells, biomaterials, and bioactive components and the concept of in situ 3D bioprinting in the lab to arrest the midmost stage of in vitro expanding cells and planting cells immediately inside the body to remedy injured tissue or organ by means of tissue engineering (fig.1). Such type of technology is minimally invasive, supplies massive features to the patients and prospects to propose a novel settlement for these ones on the suspense list. This presentation awarded a certificate of appreciation (Figure 5).

Figure 5 Invited show awarded a Certificate of Appreciation: "The latest technology in 3D bioprinting". Global TIPE 3D Printing Conference 2023, Jan 24-26, New York, USA.

Laila M. Montaser29 stated that 3D bioprinting has emerged as an optimistic modern means for laboring compound biological implants in the arena of tissue engineering and regenerative medicine. It aims to minimize the problems of traditional tissue engineering mods by scrutinizing a scheduled layer-by-layer pool of biomaterials in a desired 3D style. Cell printing targets to relocate spirited cells in a 3D sort to symbolize stem cell niches and pathological tissue morphologies for drug check or to mimic human tissue mix jobbing as biologically suitable replacements. A manageable 3D tissue engineering technology permits stem cells output from a person’s hold body to cleave after printing and identify in a path to organize and change any tissue group of the body.

Laila M. Montaser Keynote presentation30 awarded a Certificate of Recognition (Figure 6) entitled "Robotic in situ bioprinting technology for the generation of functional engineered tissues" presented at 5th Int. Conf. on3D Printing & Additive Manufacturing 2022, Aug 22-23, Singapore city, Singapore. While Montaser invited presentation31 awarded a Certificate of Recognition entitled "Robotics and Automation in Regenerative Medicine" at 3rd Global Summit on Electronics & Electrical Engineering 2023, Oct 26-28, Barcelona, Spain (Figure 7).

Figure 6 Keynote speech awarded a Certificate of Recognition entitled "Robotic in situ bioprinting technology for the generation of functional engineered tissues" presented at 5th Int. Conf. on 3D Printing & Additive Manufacturing 2022, Aug 22-23,Singapore city, Singapore.

Figure 7 Invited display awarded A Certificate of Recognition entitled "Robotics and Automation in Regenerative Medicine" presented at 3rd Global Summit on Electronics & Electrical Engineering 2023, Oct 26-28, Barcelona, Spain.

In the era of COVID-19, she was awarded forty six certificates of appreciation for successfully presenting fifty five Global Webinars 46/55 (83.6%), chairing 3 global conferences, and shared twice as organizing committee member. This was for her exceptional contribution to the commitment to provide continuing education to students and the global community from her home office during the COVID-19 crisis.

This was the most recent upshot presage of success Montaser gained after more than four year journey from the start of the pandemic by her unmatched notion of warfare the virus during the staying at home amidst the lockdown and after and until now by acting online from her home office.32–44

Entering awards is a fantastic way of celebrating what Laila M. Montaser and her work have achieved. It cannot be overestimated how much winning an award can boost my morale, increase my acting credibility and put my action in the limelight for all the proper reasons. Thinking you can be successful is the extreme chief stage indeed gaining it?

Accompanied by the furthermore optimization of present-day technologies and the appearance of additional bio-ink matters, the plan of beneficial scaffoldings for the employ of extracellular matrix, bone and cartilage stem cells is becoming extra and extra Favorable. 3D printed scaffoldings for tissue engineering could be vital to improving the fineness of lifetime for sick persons with organ disorders and dysfunction raised by harm or injuries. As well, to upgrade the organization, calibration, non-poisonous, safe, green and ecological guard of 3D printing articles, and to constantly extend the integral of 3D printing technology, stem cell technology and conventional therapy will be the evolving leadership of 3D printing and stem cell making ready. In recent years 3DP technology is evolving quickly. In the predictable after time, when 3DP is vastly applied, the world’s industrial makeup will be highly modified. Ultimately, for the fast evolution of stem cell regenerative medicine therapy, the public ethical, lawful intellectual and regulatory problems transported by printing organs and tissues are also valuable of our careful thought and profound consideration. Look forward to the utilization of movable contingency printers in developing countries and distant places. We hope that this revolutionary technology would locate large interest in various biomedical squares in the near future. We anticipate the fundamental association of regenerative medicine and additive manufacturing to be an honorable success in the service of wholeness humaneness.

None.

The author declares that there are no conflicts of interest.

None.

©2024 Montaser. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.