MOJ

eISSN: 2381-182X

Investigations were carried out on development quality evaluation and shelf life studies of buffalo meat emulsion sausage prepared by different levels of fat and skimmed milk powder (SMP) at refrigerated storage temperature (0°C). The quality of emulsion sausage was based on the basis of physico-chemical characteristics namely moisture content, pH, protein content, TBA number, microbial characteristics like total plate count, and sensory chrematistics The response surface methodology was applied to study the effect and for optimization of these ingredients. The moisture content of sausage samples prepared with different levels of fat and SMP ranged between 58.9% to 62.615% in fresh condition. After 28days of refrigerated storage (0°C), moisture content of emulsion sausage ranged between 47.62% - 52.97%. The protein content of emulsion sausage was in range of 2.015% to 2.587%. The values of TBA number of emulsion sausage were found in the range of 0.323 to 0.358. There was slight decrease in pH of emulsion sausage during refrigerated storage (0°C). There was apparent increase in fat and protein content of emulsion sausage samples during refrigerated storage (0°C) mainly due to the loss in moisture content. The total plate count of emulsion sausage was found in the range of 3.72-4.02 in fresh condition. After 28days of refrigerated storage (0°C) the values of TPC of emulsion sausage samples was found in the range of 6.97-7.245logcfu/g, this indicated the spoilage condition of emulsion sausage samples. The storage study revealed that the sausage samples came to spoilage end after 28days of refrigerated storage. It was measured by the total plate count of these samples. Therefore shelf life of the samples was found to be 21days under refrigerated condition (0°C).

Keywords: skimmed milk powder, TBA number, response surface methodology, emulsion sausage, shelf life

RSM, Response Surface Methodology; SMP, Skim Milk Powder; RCCD, Rotatable Central Composite Design; LDPE, Low Density Poly Ethylene; WOF, Warm Over Flavour

Man has satisfied his hunger with animal food from the earliest of times. The term meat refers to the muscles of warm blooded terrestrial four legged animals, the chief ones being cattle, sheep & pigs. Meat also includes the glands & organs of these animals. Meat products include many of the by-products from animal slaughter, such as animal gut used for sausage casing, the fat from the meat used in the manufacturing of lard, gelatin & others. Meat is rich in most of the nutrients required by man. This is to be expected since the tissues and body fluids of man are very similar to those of animals. Meat is rich in protein (15-20%) and contains all the essential amino acids. It is also rich in minerals and vitamins, phosphorous, copper and iron are present in significant amounts in meat. Thiamine, riboflavin and niacin occur in good amounts in all meats. Liver usually contains a useful amount of vitamin A.

Asian buffaloes dominate the world population, representing 96.4% of the worldwide population of 180.70 million as of 2008.1 Within the Asian region, about 74.8% of buffaloes are in the South, 12.8% in East Asia, and only 8.4% are found in South-East Asia. During the last 10 years, world buffalo population has increased by 20.0 Million head and 89.41% of that increases occurred in Asia, in fact, that population growth has been largely contributed by India and Pakistan. India has 98.5 Million head and Pakistan has 29.8 Million head, and combined, represents about 70.0% of the total buffalo in the world. The 1998-2008 average annual growth rate of 1.48% in Asian buffalo population is basically growth in those two countries. During the year 1981 buffalo meat production was only to the tones of 127 000 tonnes. Thereafter, a 10 fold increase was recorded during period of 1981-2004. India produced 1.5 million tonnes of buffalo meat1 which is the 36 percent of the total meat produced in the country by 10.8 million buffaloes. It was probably due to the enormous export potential of this commodity to the Middle East countries India's livestock population includes, 88 million buffaloes, which is 59 per cent of the world's buffalo population. Animals which are generally used for production of meat comprise of sheep and goats, pigs and poultry. Besides about 3600 slaughter houses, there are live modern abattoirs and one integrated abattoir meat processing plant for slaughtering buffaloes for exports and domestic consumption. There are 24 meat processing plants including 13, hundred percent export oriented units which are mainly engaged in export of meat products. In the last one-year three new export oriented units of buffalo meat processing have been approved and are reportedly under implementation. In addition, there are few animal casing units engaged in collecting cleaning, grading and exporting sheep and goat and cattle guts. The major areas for Buffalo Meat production are Maharashtra, Andhra Pradesh, Uttar Pradesh (APEDA).The ready to cook or ready to serve meat products requires less preparation and time and these are easy to serve according to convenience. There are different varieties of products in the market e.g. different types of meat sausages, meat patties etc. A sausage consists of ground meat, herbs and spices, often with some functional ingredients, and is traditionally packed in a casing made from the intestines of animals. The word sausage originally comes from the Latin word “salsus”, which means salted or preserved. It is often assumed that sausages were invented by the Sumerians (in what is Iraq today), around 3000BC. Judicious utilization of milk proteins (Proteinaceous products from the surplus skim milk of dairy industry) improves the sensory quality and nutritive value of comminuted meat products. Presently, researchers have focused increasing attention to utilize milk proteins as fillers, binders and extenders in various processed meat products.2 Milk proteins such as casein and caseinates, co-precipitates, skim milk power and whey proteins etc. substituted more expensive meat proteins and maximized the yield of the product. Dairy proteins improved emulsifying capacity, emulsions stability and water holding capacity of the batter and slicing characteristics of the product. In addition, the nutritive value of the end product is enhanced by their excellent amino acid profile, besides improving sensory characteristic of the finished product. Several workers attempted to improve comminuted meat products using caseinates. Similar studies were conducted by Singh et al.3 for snack sausage incorporated with rice flour and sodium caseinate by Mandal et al.4 for incorporation of decolorized globins protein isolate on sausage. There are different types of sausages available in the market according to their typical flavor, texture, shape, taste and their geographical location e.g. Frankfurt, braunsch weiger, cotto, salami etc. The emulsion sausage is the product, which is prepared from buffalo meat, fat, condiments, spices and meat extenders like skimmed milk powder, soy protein concentrate. Keeping in view buffalo meat as potential source for development of emulsion sausages, the study was conducted with objectives of investigation to develop and conduct studies on quality and shelf life of buffalo meat emulsion sausages with different levels of fat and skimmed milk powder according to the Response Surface Methodology (RSM).

Experimental design

The independent variables (factors) in present study were fat and skim milk powder (SMP). The levels of these factors were generated by applying rotatable central composite design (RCCD). The RCCD suits for fitting quadratic surface, which usually works well for optimization composition. Lower and higher levels of both the ingredients were selected on the basis of preliminary trials.

The CCD for two factors response comprises of following the basis of preliminary trials.

Meat samples collected from the local meat shop in the study were from buffaloes slaughtered according to traditional halal method at slaughterhouse of municipal corporation, Aligarh. The animals were kept in lairage for a period of 18-20 hours. Meat samples from round portion (biceps femoris muscle) of 2.5, 3 and 3.5 years aged female carcasses of good finish, were obtained from meat shop within 4 hr. of slaughter. Buffalo fat from brisket and back and along with other meat ingredients. The meet chunks (13 kg) were packed in Low density poly ethylene (LDPE) and brought to the laboratory with in 20 min. buffalo fat (2.4 kg) were also packed in LDPE and brought to the laboratory. Other non-meat ingredients like spices, salt, condiments and combination film were procured from the local market. This fibrous casing was procured from PRS technologies New Delhi.

For the preparation of buffalo meat emulsion sausage, the minced lean meat was chopped in a bowl chopper to the final degree of grinding so that quality of the finished product may improve. During chopping, the other ingredients animal fat, SMP, spices, salt, condiments, MSG, sodium ascorbate, were added in the minced lean meat, and some ice are added in order to make stable emulsion, when complete emulsion was formed, the meat mix was transferred to stuffer/sausage filler machine.

Meat mix was immediately molded into sausage with the help of sausage filler machine to give final shape. The cooking of sausage was done in steam cooker for 25 minutes at 100°C, after cooking it was cooled and casing was removed then finally packed in combination film under atmospheric packaging. The samples of sausage kept under refrigerated storage at 0°C for storage study. The pH of the finally minced samples were determined after homogenizing 10g of the sample with 100 ml distilled water using laboratory grinder (Yarco, India). The pH of suspension was recorded using reference and glass electrode portable type Digital pH meter (model PH1500, (Eutech, Singapore).

Moisture content of emulsion sausage was determined by hot air ovemethod. 5 g of the sample was kept in hot air oven at 150oC for half an hour.5,6 Fat content was estimated by AOAC as described by.7 Protein was estimated by method of IECA as described by.7 TBA number was measured by the method described by Strange et al.8 Five ml of TCA extract was mixed with 5ml of TBA reagent in test tube. The test tube was kept in a water bath at 100o C for 30 min along with another test tube containing a blank of 10% TCA and 5 ml of TBA reagent. After cooling the tubes in running water about 10 min, the absorbance was measured at 530 nm in a spectrophotometer (Digital spectrophotometer Model 310E, India) and reported as TBA number. TBA number was measured by the method described by Strange et al.8 Five ml of TCA extract was mixed with 5ml of TBA reagent in test tube. The test tube was kept in a water bath at 100o C for 30 min along with another test tube containing a blank of 10% TCA and 5 ml of TBA reagent. After cooling the tubes in running water about 10min, the absorbance was measured at 530nmin a spectrophotometer (Digital spectrophotometer Model 310E, India) and reported as TBA number. All the samples were evaluated for direct plate count using serial dilution spread plate technique with nutrient agar medium for total plate count .9 Microbiological characteristics of sausage samples were evaluated in fresh conditions and during refrigerated storage (2 oC) after constant intervals. For determination of total plate count the samples were taken with sterile knife, comminuted to fine particles in a tissue homogenizer (Yarco, India) and then transferred to a test tube containing 9 ml of normal saline solutions. The samples were homogenized in the cyclomixer (mode CM-101, India). Serial dilutions were made by transferring 1 ml of the extract from each dilution and finally the samples were inoculated in the petridishes containing the solid medium. The colonies were counted after 24-48 hr incubation in BOD incubator (York Scientific, India).

Data obtained from experimental observation (n=5), were subjected to analysis of variance (Two ways ANOVA). All statistical analyses were performed using factorial design as suggested by.10

The present study was undertaken for development, quality and shelf life studies of buffalo meat emulsion sausage produced by using different levels of fats and skimmed milk powder (SMP). The quality of fresh sausage was evaluated on the basis of physico-chemical characteristics namely pH, moisture content, protein content, ash content, fat content, and TBA number, microbiological characteristic total plate count and sensory characteristics and colour measurement by Hunter Lab.

In the first experiment the composition of the emulsion sausage was optimized using Response Surface Methodology. In the next experiment shelf life study was undertaken. To evaluate the shelf life under refrigerated condition the samples of emulsion sausage were packed in combination films with air packaging and kept for storage study at 0°C. The results of the study have been presented in different tables and graphs and are discussed below:

Effect of Factors Levels (Fat and SMP) on Various Responses

The effect of Fat and SMP on various physico-chemical and microbiological properties of fresh samples of emulsion sausage have been summarized in Table 1.

Std |

Run |

Fat% |

SMP% |

Moisture Content% |

Fat Content % |

Protein Content % |

pH |

TBA No. |

TPC |

11 |

1 |

30 |

2.25 |

60.65 |

15.05 |

18.73 |

6.46 |

0.34 |

3.98 |

4 |

2 |

20.07 |

0.65 |

62.36 |

14.56 |

17.82 |

6.46 |

0.32 |

3.37 |

19 |

3 |

20 |

2.25 |

58.40 |

13.42 |

18.04 |

6.19 |

0.31 |

3.12 |

6 |

4 |

12.92 |

3.84 |

58.12 |

10.48 |

18.31 |

6.4 |

0.31 |

3.56 |

16 |

5 |

20 |

4.5 |

60.93 |

14.70 |

18.52 |

6.21 |

0.34 |

3.44 |

10 |

6 |

10 |

2.25 |

56.46 |

10.26 |

18.11 |

6.09 |

0.35 |

4.01 |

8 |

7 |

27.07 |

3.84 |

64.71 |

15.18 |

18.35 |

6.34 |

0.33 |

3.98 |

17 |

8 |

20 |

2.25 |

62.9 |

14.47 |

19.51 |

6.23 |

0.36 |

4.08 |

12 |

9 |

30 |

2.25 |

59.66 |

16.37 |

18.15 |

6.12 |

.29 |

3.88 |

13 |

10 |

20 |

0 |

59.53 |

14.55 |

17.55 |

6.13 |

0.38 |

4.1 |

9 |

11 |

10 |

2.25 |

59.34 |

10.28 |

19.27 |

6.14 |

0.35 |

3.88 |

15 |

12 |

20 |

4.5 |

62.71 |

14.86 |

18.59 |

6.16 |

0.37 |

4.11 |

1 |

13 |

12.92 |

0.65 |

58.45 |

12.93 |

18.27 |

6.10 |

0.32 |

3.87 |

18 |

14 |

20 |

2.25 |

62.19 |

14.35 |

18.85 |

6.25 |

0.33 |

4.08 |

3 |

15 |

27.07 |

0.65 |

61.87 |

14.68 |

18.88 |

6.24 |

0.39 |

4.08 |

14 |

16 |

20 |

0 |

61.54 |

13.47 |

18.37 |

6.16 |

0.36 |

3.78 |

5 |

17 |

12.92 |

3.84 |

59.85 |

11.88 |

18.60 |

6.40 |

0.33 |

4.09 |

2 |

18 |

12.92 |

0.65 |

55.98 |

12.05 |

18.30 |

6.09 |

0.34 |

3.89 |

7 |

19 |

27.07 |

3.84 |

60.52 |

16.38 |

19.51 |

6.15 |

0.34 |

4.07 |

Table 1 Physico-chemical and microbiological properties of fresh samples of emulsion sausages

Data obtained from experimental observation (n=5), were subjected to analysis of variance (Two ways ANOVA). All statistical analyses were performed using SPSS Version 10.0 for Windows (SPSS Inc., Chicago, IL, USA) as described by Field (2005)

Effect on moisture content

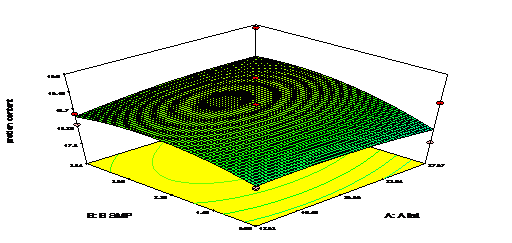

Moisture content of fresh emulsion sausage is an important characteristic, which relates the quality and shelf life. The moisture content is an important property influencing storage stability and texture of foods. Higher the moisture containing foods are more prone to microbial spoilage but they have softer texture. Figure 1 shows the 3D response surface plot, dependency of emulsion sausage moisture content on fat and SMP. The regression model obtain for moisture content has been shown as give below:

Figure 1 3D response surface plot, showing the dependency of emulsion sausage moisture content on fat and SMP.

Effect on protein content

Protein content of emusion sausage is an important characteristic, which relates the quality and shelf life. The protein is the third major class of nutrients. There are thousands of proteins founds in nature which vary in their composition and size. All the proteins contain the elements carbon, hydrogen, oxygen and nitrogen. A good quantity of protein is essential for proper growth. Figure 2 shows 3D response surface plot, the dependency of emulsion sausage protein content on fat and SMP.

Figure 2 3D response surface plot, showing the dependency of emulsion sausage Protein content on fat and SMP.

The quadratic model was suggested by the analysis and was found not significant on the analysis of variance at (p>.5460), the quadratic model shows low R2= 0.2437. The coefficient of quadratic term of factors indicates, that the protein content is negatively correlated with fat and SMP. The F value shows that the fat affected more as compared to SMP. Starting from the intial point (A= 12.93%, B= 0.66%) the protein content was found to be 18.27%. Figure 3 shows the protein content profile of emulsion sausages samples during refrigerated storage (0°C). The linear regression of this graph has been shown on the regression graph. The equation of regression lines and correlation coefficients are shown on the regression graphs. The positive sign in the coefficients of x explain that there was slight increase of protein content during refrigerated storage. The correlation coefficient values explain the correlation between protein content and storage days. The increasing nature of protein content with storage time was perfect at R2=1, the values of R2 for all samples were found near 1 which shows that correlation are almost perfect and the graphs may be approximated to a straight line.

Effect on pH

Samples after preparation were packed by atmosphere pacakaging. pH plays an important role in preservation of foods. Generally high acidic foods are less prone to bacterial spoilage but have chance to mold spoilage. Following equation is the regression model obtain for pH.

pH = +6.23 + 0.044* A + 0.035 * B -0.10 * A * B + 0.011 * A2 -8.479E-003 * B2

The quadratic model was suggested by the analysis and was found not significant on the analysis of variance at (p>0.0904), the quadratic model shows low R2= 0.4844. The coefficient of quadratic term of factors indicates, that the pH is positively correlated with fat and SMP. The F value shows that the SMP Affected more as compared to fat. Starting from the intial point (A= 12.93%, B= 0.66%) the pH content was found to be 6.101. Figure 4 shows 3D response surface plot, the dependency of emulsion sausage PH on fat and SMP.

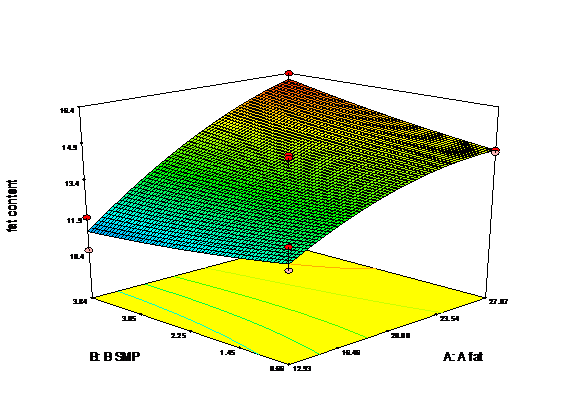

The fat content of fresh sausage were determined and it vary in the range 11.27 % to 15.761%. Figure 5 shows 3D response surface plot, the dependency of emulsion sausage Fat content on fat and SMP.

There is comparatively increase in fat content of sausage samples during refrigerated storage (0°C) due to the decrease in moisture content of emulsion sausage. Fat content of emulsion sausage is evaluated before and during refrigerated storage at 0°C. Figure 6 shows the fat content profile of emulsion sausages samples during refrigerated storage (0°C). The linear regression of this graph has been shown on the regression graph. The equation of regression lines and correlation coefficients are shown on the regression graphs. The positive sign in the coefficients of x explain that there was increase of fat content during refrigerated storage. The correlation coefficient values explain the correlation between fat content and storage days. The increasing nature of fat content with storage time was perfect at R2=1, the values of R2 for all samples were found near 1 which shows that correlation are almost perfect and the graphs may be approximated to a straight line.

Figure 5 3D response surface plot, showing the dependency of emulsion sausage fat content on fat and SMP.

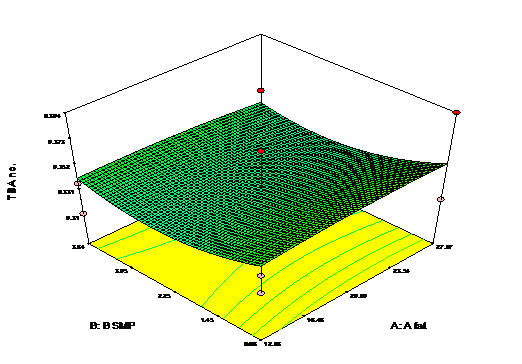

Figure 7 3D response surface plot, showing the dependency of emulsion sausage TBA no. on fat and SMP.

Effect on TBA number

Thiobarbituric acid (TBA) number is important relevant characteristics of meat product that indicates the oxidation state and later on rancidity of the product. TBA numbers were highly correlated with sensory score of trained penalists for rancidity odour in meat and meat products.11 The buffalo meat emulsion sausage after preparation were packed in combinational film under atmospheric packaging systems. The samples contained sufficient fat and therefore developed warm over flavour (WOF). The WOF is related to sensory quality of the products which is unacceptable by the onsumer. Following equation is the regression model obtain for TBA number:-

TBA no. = +0.34+2.119E-004*A-5.886E-003*B-2.000E-003*A*Bn2.187E003*A2+ 0.013*B2

The quadratic model was suggested by the analysis and was found not significant on the analysis of variance at (p>0.5930), the quadratic model shows low R2= 0.2266. The coefficient of quadratic term of factors indicates, that the TBA number is positively correlated with fat and negatively correlated with SMP. The F value shows that the fat affected TBA number more as compared to SMP. Starting from the intial point (A= 12.93%, B= 0.66%) the TBA number was found to be 0.326. Figure 7 shows 3D response surface plot, the dependency of emulsion sausage TBA on fat and SMP.

TPC

TPC no. is one of the important microbiological parameter used to determine the shelf life of the product. A microbial population of 107/g or above was indicative of spoilage.5,6,12,13 TPC of emulsion sausage is evaluated before and during refrigerated storage at 0°C.

The linear regression of this graph has been shown on the regression graph. The equation of regression lines and correlation coefficients are shown on the regression graphs. The positive sign in the coefficients of x explain that there was increase in TPC during refrigerated storage. The correlation coefficient values explain the correlation between TPC values and storage days. The increasing nature of TPC with storage time was perfect at R2=1, the values of R2 for all samples were found near 1 which shows that correlation are almost perfect and the graphs may be approximated to a straight line. Figure 8 shows the TPC profile of emulsion sausages samples during refrigerated storage (0°C).

Studies were conducted for development, quality evaluation and shelf life of buffalo meat emulsion sausage developed from different levels of fat and skimmed milk powder (SMP) as meat extenders. The levels of fat ranged from 10 to 30% and SMP level ranging from 0 to 4.5%. The SMP also used as a fat mimicking system in meat formulation. The importance of fat mimicking system is to reduce fat and cholesterol in the diet.

The response surface methodology was applied to study the effect and for optimization of these ingredients.

Moisture content of emulsion sausage was found in the range 64.71-56.46 and protein was in the range 19.51-17.55. These values provided juiciness and enough protein for nutritional requirement as per NIN standard.

The values of TBA number of samples of emulsion sausage were found in the range of range of 0.323 to 0.374. During 28 days of refrigerated storage (0°C), values of TBA number increased in the ranged 0.762 to 0.893.

The sample of cooked sausage was grayish brown colour in appearance. Hue values were found in the range 4.88-6.98. The emulsion sausage lost its colour during refrigerated storage and studies were carried out till 28 days.

The total plate count of emulsion sausage was found in the range between 3.72-4.02 in fresh condition. After 28 days of refrigerated storage (0°C) the values of TPC of emulsion sausage samples was ranged in between 6.97 -7.245 log cfu/g, this indicated the spoilage condition of emulsion sausage samples. The storage study revealed that the sausage samples came to spoilage end after 28 days of refrigerated storage. It was measured by the total plate count of these samples. Therefore shelf life of the samples was found to be 21 days under refrigerated condition (0°C).

The authors greatly acknowledges the fund received from Indian Consul of Agricultural Research in Adhoc Research Project that enable this work be conducted.

The author declares no conflict of interest.

© . This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.