eISSN: 2577-8307

Research Article Volume 3 Issue 4

Olasgarden Forest & Roads, Sweden

Correspondence: Iwan Wästerlund, Olasgarden Forest & Roads, Solvägen 9, 918 32 Sävar, Sweden

Received: October 24, 2019 | Published: October 22, 2019

Citation: Wästerlund I. Handling of forest fuel from a logistical point of view, - a critical scrutinizing. Forest Res Eng Int J. 2019;3(3):120-123. DOI: 10.15406/freij.2019.03.00088

Today there are too great losses in the forest fuel supply chain from the forest to the consumer. Although if 150MWh/ha can be collected after a clear cut, maybe only 55% of that is used for combustion. Better logistic is needed with better focus on upgrading at each node. With good packaging technique 65-75% may be reachable and with long tops maybe 5% more forest fuel can be delivered for combustion. On top there could also be a better fuel quality with packaging of the material giving better handling utility.

Keywords: Storage losses, transport efficiency, control

CRL, composite residue logs, CNP, passive node time; CA8, components in the cycle time; CN, node time is handling of material in the node, Cn, can be divided in passive, active; Cna, active; C1, link time

Forest fuel handling in Sweden has developed from the first oil crisis in the 70-ties,1 if firewood handling is excluded. There have been many studies on efficiency and system analyses made on forest fuel handling in many cases the whole logistic chain is not considered. One major obstacle in the supply chain is the usual strong seasonal variation in consumption, which in the Nordic countries is connected to the need of heating during the winter period. Logging residues are normally produced the year around at about same rate. Thus, storage is needed but the question is how to make storing to improve the following chain and moreover to reduce losses of material (energy). The latter thing seems not to have been a major issue (maybe with the exception of decomposition). The goal must be to improve the whole chain with upgrading to both increase transport efficiency and not loose fuel amounts and fuel quality.

The aim was to describe the flow chain of forest fuel, mainly as logging residues, from forest to combustion, with a logistic approach from material and energy use perspectives.

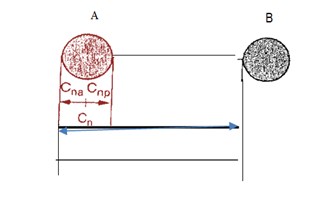

The idea to the concept came from literature on technical logistics.2 Logistics means right material to right price at right time and right place with right information. Technical logistic involves description of material flow with nodes for storage and link for transports (Figure l) and such description helps to give a good overview on how the material is handled.

Figure 1 CA8, CA8, Components in the cycle time; CN, Node time is handling of material in the node, Cn, can be divided in passive, active; Cna, active; C1, Link time is the transport time.2

Of relevance for the forest fuel logistic chain is also to introduce three functions. One is the local utility which means that the material is moved to localization where the material has a greater value. The second is Handling utility, which means a reorganization of a product to fit better in the chain, and thirdly the Time utility, which means that the service is made when it is needed.

This approach was applied on the supply chain for forest fuel and every time the fuel was left for a while, it was considered as a node. This supply chain was filled in with help of mainly literature data. Another approach could be to describe the passive node time (CNP) as is done for goods transport efficiency. Such approach would, however, give too high values to be of logistical interest.

Result from this investigation is presented below mainly as a discussion to highlight the problem and initiate further research with higher focus on the supply chain instead of single operations.

Amounts of raw material

Today the main sources for forest fuel are residues at upgrading of timber and pulp (e.g. bark, sawdust etc) or tree residues from the forest (mainly clear-cuttings). The latter part constitutes about 19TWh in Swedish energy supply and is increasing considerably the last year due to several factors.3

Let’s concentrate to logging residues from clear-cuttings. Roughly 25% of the standing biomass at clear cut consists of branches, needles and tops.4 A forest could have 180-400m3 above stump and about 45-100m3s (solid) could be residues. If the density is put to be 0.4 kg m-3,5 and the energy content could be put to 19.5kJkg-1 dry matters.6 This means 97-216MWh ha-1 (19.5kJ=5.41kWh) should be available after clear cutting.

At clear cutting usually a fuel adapted cutting is made which means that delimbing is done on a separate place leaving branches and tops on a well separated pile from sawn timber and pulp wood. This work done by the harvester may cost roughly 2-7% of the harvesting cost,7,8 although very few of the contractors are paid for this work. In the northern part of Sweden, the dominating model is to transport the logging residues to road side with a forwarder, whereas in southern Sweden it is common to chip the residues already on the harvesting area. Here the former part is considered as a major line for the presentation.

There seems to be very few studies conducted on how much of the present material as logging residues on the clear-cut area and how much that is really collected. Jacobson9noted in one study 87%, which seems to be almost an extremely high figure. From a practical and economic perspective often 70-80% is considered as a normal value. From fuel adapted harvesting it should be possible to reach 80-85% recovery. Next step involves a new choice: Should the green material be collected at once to use present machinery or wait till the material has become brown with decreased amounts of needles and be a better fuel for many incineration places. If the material is left during the summer, the amount of needles may sink from about 25-27% to maybe 5-7% if placed on the cutting area, and to about 10-15% if placed on a high storage at forest road. These figures will vary considerably with storing conditions and given mainly as examples. After similar types of storage studies there appear to very little information of material amounts and quality really entering the combustion unit.

Consider a chain with economy in focus, thus forwarding of green material soon after harvest of timber. Then about 85% of material is collected and brought to roadside with a forwarder. Forwarding of logging residues may utilize only 40-50% of the loading capacity of the forwarder according to some company figures. This means the forwarding of logging residues cost roughly twice as much as timber transports. Storing on clear cut area cannot be considered as being active storage. Still the forest owner can ask the question for what he/she is being paid for. Furthermore, maybe 25% of the energy used for collection of logging residues is used for transporting air and water!

Transport from roadside to consumer

At storing at roadside further material is lost through microbial activity but also chemical changes will occur. The amount of losses will increase with increased amount of combination, temperature and moisture conditions. Storing at roadside of green material will create great losses of needles. As mentioned above, a half year storing may cause about 20% losses, mainly as of needles and small twigs, often to be left at ditch side. At loading of the lorries, it may be estimated that about 5% more of the material leaving cut block is left at road side. Furthermore, there will some degradation of the material lying in the pile. Most likely some extractives will disappear giving some less energy values. Typically, it seems that from 20, 5kJkg-1 from fresh spruce logging residues, the gross calorific value may go down to about 19. 6kJkg-1 for stored logging residues. This indicates from an energy point of view that the total energy content in the pile has decreased 0.8times 0.80times 0.96, which equals 0.69. Thus, storing at roadside of green material has reduced the amount recovered energy to 61%.

The active part if this storage is drying of the material- if using millboard covering-and some losses of alkali metals and silica as dominating material in the needles. This part is not paid for, since there is no incitement of payment for residue quality.

The road transport of logging residues is often done with a lorry with covered sides. Unfortunately, this covering of the sides reduces quite a lot the loading capacity of the lorry. The Tara weight is often reaching up to 35Mg giving only 15Mg load for a maximum of 60Mg used in Finland and Sweden. This can be compared to timber transport where usually 38-40Mg is the payload. Thus, the payload at road transport is only about 40% when transporting loose logging residues.

Buyer handling

At buyers place the material is weighted on a lorry scale. This is usually the first place where there is a measurement of the material gathered at logging site. Of course, there is no incitement for the buyer to pay for the losses occurred before entering the factory gate. At the consumers landing the material may be stored for about one month waiting for combination. Here further 5% losses may occur. After combination the material may be put up in big piles, to be a part of the wanted product mix for the heating plant. Often this pile could be kept for more than one month. Logging residues are very rich in nutrients and already infected with microbial and the degradation continues fast, especially if storage outdoor which is the usual case. According Jirjis & Theander,10 6 months storage could cause about 20% losses of material, indicating about 1% loss per week of storing. In the present case loss of material from residue storing was 5% and furthermore 5% was lost after combination. At this place the losses were in the area of 10%. Thus, from the start at the cutting block there is only 55% left of the energy to be used, leaving carbon dioxide to be used by microbial and spontaneous chemical activity outside heating plant (Figure 2). Furthermore, a lot of energy is spent on using transport agent driving "half empty".

A great part of the losses has occurred during passive storing. The active part in the nodes can be said to be reduction of alkali and silica (mainly due to losses of needles) and some drying of the material. The question is if drying of material is a wanted matter. Right material for some modern heating plants may be a material with a moisture content of maybe 50% if they have an installed condenser for recovery of warmth in the steam gases. Is right material coming to right place at right quality?

Alternative 1: Long tops

The present top diameter for pulp wood is usually 6cm and can be utilized completely where falling lengths are used (mainly northern part of Sweden). Brunberg et al. have made a good investigation on the economy by changing the top diameter at forest fuel selling. By increasing the top diameter from 6 to 10 or even 12cm, the amount of forest fuel will increase with 4 and 16% respectively, while the amount of pulpwood will sink with 11 and 64% respectively (timber dimensions unchanged). With the prices and performances, they calculated with, the best economy in the whole logging chain was received at 10cm top diameter. This is also used at one Swedish company during quite long time in northern part of Sweden determining the amounts of pulpwood and forest fuel to take out depending on present prices.

A possible scenario for Sweden could be to raise the top diameter between pulpwood and forest fuel to 10cm, which would give further 5-8MWh per ha in forest fuel delivery. Since the new material is rather course, it is possible that this amount would give a proportionally higher recovery for customer (+6-8%). Most likely in that case the top diameter of small timber would be raised causing a minor reduction of pulpwood to less than 5 %.

Since this material is less prone for degradation, the 6-8% increase of material would most likely mean that at least 5% of it is to be found in the heating plant. Thus, by increasing sizes of material the losses should be reduced.

Alternative 2: bundling

Limiting factor for the economy in the supply chain is often the concentration of the raw material. The cost for handling of forest fuel from clear cut area to buyer is often in the area of 100-110SEK per MWh.8 With a fuel price during 2004 on 110SEK per MWh the profit for this operation seems limited. One way could be to make a package of the material, thus invest at cut area to make handling cheaper later on. Bales have been introduced for about 10 years ago and tests in Sweden and UK have shown that transport costs can be considerably reduced. The unexpected part was that chippers could not take those big bales (1.2m in diameter) and the efficiency in the chain was broken.

Later on two types of bundling machines appeared on the market (Fiberpac and Wood Pac). The first one compresses the material and ties strings around the bundle and finally cuts the bundle to the desired length, e.g. 3-4m. The second (Wood Pac) tumbles the material within a compartment with spiked rollers, which shave off some of the fine material (mainly needles and twigs) and produces 3.4m long bundles. Finally, strings are tied around the bundle, which is then released from the compartment and falls to the ground. Those bundles are 0.7min diameter, also called composite residue logs (CRL), can be handled in bigger chippers/crushers.

Productivity studies on these bundling machines indicate a performance of about 20- 25 bundles per hour with a gross calorific value of 1.5MWh per bundle Andersson et al.8 The cost for the operation could be around 25-30SEK per MWh but on the other hand transport costs may be reduced to half, balancing bundling costs. The revenue comes for storing and combination with good capacity utilisation. The most important thing may be the storing possibilities for a bundle. After 9 months storing, about 10% material was lost but the energy content had rather increased than decreased.

The Wood Pac machine will leave fine material on the clear-cut area shaved off from the residues. This will reduce the productivity of the machine and the amount of collected material but on the other hand both increasing the quality of the product for combustion and leaving less wanted material behind already out at the forest and not along roadside. Up to 20% of the green material could be shaved off, mainly as needles and twigs returning about 11% of nitrogen and 25% of phosphorus in the logging residues.

None of the bundling machines are perfect and the sizes of the bundles must be re considered to fit the following chain. However, the technique to make a package of the material is a good example of what is indicated above: The goods should be put in a suitable handling unit to both improve quality and easy handling in the supply chain. With a just compressing unit it can be estimated that the recovery at combustion could be up to 75% but in that case also containing lots of needles. With Wood Pac bundling only 65-70% of the material is coming to the heating plant but with less needles and a good deal of the nutrients left where they belong.

In conclusion, the following points can be made:

Present handling of logging residues could be improved to give a more efficient supply chain, both in quality and energy use.

There is too much passive storing in the present supply chain!

A good packaging of the material is needed and should be considered but to reasonable costs to give good handling utility.

The package must fit to the supply chain and have a local utility.

This article may upset active persons/companies in the wood-fuel business and I welcome a discussion on the topic. However, the idea with the article is to point out three things: We have poor knowledge of the material flow in this supply chain, there should be better specifications on wood fuel quality, and finally, we need better studies of the whole supply chain to give input to a fruitful discussion.

None.

None.

Author declares that there is no conflict of interest.

©2019 Wästerlund. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.