Journal of

eISSN: 2373-4310

Research Article Volume 4 Issue 3

1Senior Research Fellow, Department of Food Science and Nutrition, Banasthali Vidyapith, India

2Research Scholar, Department of Food Science and Nutrition, Banasthali Vidyapith, India

3Associate Professor, Department of Food Science and Nutrition, Banasthali Vidyapith, India

Correspondence: Monika Jain, Associate Professor, Department of Food Science and Nutrition, Banasthali Vidyapith, Rajasthan, P.O. Banasthali Vidyapith-304022 (Rajasthan), India, Tel 098-872-810-46, Fax 014-382-285-87

Received: October 25, 2015 | Published: May 13, 2016

Citation: Gupta K, Srivastava S, Jain P, et al. Process optimization for formulating Trigonella foenum-graecum and Gymnema sylvestre added vegetable cereal mix using response surface methodology. J Nutr Health Food Eng. 2016;4(3):416-428. DOI: 10.15406/jnhfe.2016.04.00129

Trigonella foenum-graecum seeds and Gymnema sylvestre leaves are health promoting food ingredients which are particularly beneficial for individuals suffering from diabetes mellitus. In order to promote their incorporation in diet, vegetable cereal mix was formulated as a dried food product with extended shelf life, which could be easily reconstituted for consumption. Response surface methodology and central composite design were used in optimization of vegetable cereal mix. The objective was to devise the best combination of process variables and obtain optimal recipe having minimum fat, maximum fiber, in-range carbohydrate and maximum overall acceptability. Three quantitative controllable factors were selected for the experimental design: amount of Trigonella foenum-graecum, soaking time of Trigonella foenum-graecum and amount of Gymnema sylvestre as process parameters. Response variables were fat, fiber, carbohydrate and overall acceptability. Regression models and response surface plots were generated and adequacy was tested with regression coefficients and the lack of fit tests. Sensory, physico-chemical and microbiological analysis were undertaken for optimized recipe. The optimum recipe had 8.0g Trigonella foenum-graecum with 8.0hours soaking time and 5.0g Gymnema sylvestre with 0.48g fat, 3.01g crude fiber, 29.84g carbohydrate and 89.17 overall acceptability score. Results indicated that optimized product obtained good scores for all sensory attributes and had good shelf life. This vegetable cereal mix was nutritionally adequate and had desirable sensory quality.

Keywords: Gymnema sylvestre, process optimization, response surface methodology, Trigonella foenum-graecum, vegetable cereal mix

ANOVA, analysis of variance; CCD, central composite design; CV, coefficient of variation; R2, regression coefficient; RSM, response surface methodology

Trigonella foenum-graecum (fenugreek seeds) and Gymnema sylvestre (gurmer leaves) have some significant health benefits.1‒3 Trigonella foenum-graecum seeds play important role in antidiabetic activity. They have high mucilaginous fiber content, alkaloids (i.e., trigonelline, gentianine, capaine), sapogenins (yamogenin, gitogenin, neotigogens), high protein and micronutrient content.4,5 These seeds contain a unique free amino acid 4-hydroxy isoleucine (4-OH-lle) that has been characterized as one of the active ingredients for blood glucose control.6 They are used to prepare extracts or powder for different medicinal uses7 due to their hypoglycaemic,8 hypocholestrolemic,9,10 gastro-protective, anti-inflammatory,11,12 anti-ulcer13 and anti-carcinogenic14 properties. They enhance insulin release in body.15 Several experimental studies have confirmed the antidiabetic potential of Trigonella foenum-graecum.16‒18 Twenty five g of Trigonella foenum-graecum seeds powder (divided into two equal doses) have been used to treat diabetes mellitus.19‒22 Flour fortified with 8-10% Trigonella foenum-graecum has been used in formulation of different bakery products, i.e., bread, cakes, muffins and pizza with acceptable sensory properties.23 These seeds are relatively safe24 and have no genotoxicity.6 Gymnema sylvestre is an Indian herb used in Ayurvedic treatment (the traditional Hindu system of medicine) due to its pharmacological properties, i.e., hypoglycemic, hypocholesterolemic, hypotensive, antiobesity, antimicrobial, free radical scavenging and anti-inflammatory.25,26 It is promoted as a ‘sugar blocker’ in US markets.27,28 It is a potential natural alternative to chemical means of blood sugar regulation.29 It enhances the endogenous insulin production by increasing the number of β-cells in pancreas.30‒32 Leaves of Gymnema sylvestre contain glycosides, gymnemic acid, saponins, phytosterols, phenols, flavonoids, tannins and quercitol.33,34 Dosage of Gymnema sylvestre used in Ayurvedic medicine varies between 6 to 60g of dry or powdered leaf per day.35‒37 Trigonella foenum-graecum are bitter in taste, thus, their incorporation in high quantity can compromise overall acceptability of formulated food product. Therefore, techniques are required to produce optimum solutions for formulation of nutritionally adequate and organoleptically acceptable food product. One such technique is process optimization which can be used for development of optimum foods with enhanced nutritional qualities. Response surface methodology (RSM) has been used to develop and optimize biochemical and biotechnological processes related to food system.38 In this study, RSM has been used for process optimization because it reduces the number of experiments needed to evaluate multiple parameters and their interactions, therefore, it is less time consuming39 and provides sufficient information for statistically valid results.40

Selection of appropriate delivery vehicle is important to get the benefits of Trigonella foenum-graecum seeds and Gymnema sylvestre leaves in diet. Staple foods are widely used as delivery vehicle for this purpose. Several dry mixes based on staple foods (rice and wheat) have been used in ready to reconstitute forms, with enhanced shelf life.41‒44 Wheat is used as a staple cereal in India, hence, it was used as a delivery vehicle for the formulation of the mix.

Trigonella foenum-graecum seeds have been used in development of therapeutic diabetic foods by various researchers (upma mix, enteral feed)43,44 but its combination with other therapeutic ingredients has not yet been tried out. There is a need to come up with more food products and processes to enable incorporation of these health promoting ingredients without compromising the taste and acceptability of food item. In modern era, where life is fast paced, individuals prefer instant foods which are convenient, simple, easy to prepare and have enhanced shelf life.45 Therefore, in present study an attempt was made to develop an instant food- vegetable cereal mix incorporating Trigonella foenum-graecum and Gymnema sylvestre and to investigate the optimal combination to yield maximum fiber and high acceptability using central composite rotable design of RSM.

This study was conducted in Banasthali University (Banasthali Vidyapith), Rajasthan, India in between July, 2014 to April 2015. Trigonella foenum-graecum seeds, defatted soy flour and Gymnema sylvestre leaves powder were obtained from local market of Sitapur (Uttar Pradesh) while tomato and semolina were procured from the local market of Banasthali University and used in the formulation of vegetable cereal mix. The ingredients used in reconstitution, plain buttermilk, table salt and cumin seeds of reputed brands were also procured from the local market of Banasthali University.

Formulation of vegetable cereal mix

Vegetable cereal mix was prepared by adding Trigonella foenum-graecum powder, Gymnema sylvestre powder, tomato powder, defatted soy flour and semolina. Trigonella foenum-graecum seeds were taken, cleaned and steeped in water (at room temperature) for eighthours, dried and grinded while dried Gymnema sylvestre leaves powder was used without any further processing. Fresh tomatoes were washed thoroughly, sliced thinly and blanched (hot water) for 2minutes. They were dried in hot air oven at 60˚C and were grinded to prepare tomato powder. Cumin powder was prepared by roasting and grinding of cumin seeds. Vegetable cereal mix was prepared by incorporating Trigonella foenum-graecum seed powder (5g), Gymnema sylvestre powder (5g), tomato powder (10g), semolina (10g) and defatted soy flour (20g). All ingredients were roasted separately on low-medium flame and then they were mixed proportionally. Prepared mix was stored in auto sealed sachets and put into air tight container. Weighed quantity of 25g vegetable cereal mix was reconstituted by adding 100ml buttermilk (Saras, plain buttermilk) in thick drink for sensory analysis. A pinch of table salt and roasted cumin powder was added to it. Total 50g product was formulated which was appropriate for 2 servings.

Design of experiments

The process optimization of developed product was carried out using response surface methodology (RSM). RSM is a collection of statistical and mathematical techniques useful for developing, improving, and optimizing process.46 For this purpose a central composite rotable design (CCRD) with three process variables at five levels was used to determine the optimal conditions in the formulation of vegetable cereal mix (Table 1), which resulted in 20 experimental runs when replicated six times at the center point (0) combination. Central composite design consists of three points namely factorial points, centre points and star points that allows estimation of curvature. The distance between the centre of the design space to factorial point is ±1 unit to each process variable and the distance from the centre of design space to a star point is ±α.47 On the basis of one- at-a-time preliminary experiments, the critical factors (independent variables), amount of Trigonella foenum-graecum, soaking time (hours) and amount of Gymnema sylvestre were chosen for the optimization. According to CCRD design, the total number of experiments is (2)n + 2n + central points, where n represents the number of variables. Here the number of variable is three, therefore, total number of experiments for each critical factor will be equal to 20. In each experiment the five different levels were coded as –α, -1, 0,1 and α; where α=2n/4=23/4=1.682. Hence, the process variables coded were -1.682 (lowest), 0 (middle) and 1.682 (highest). The effects of these critical factors were seen on response variables- fat, fiber, carbohydrate and overall acceptability. Twenty sample combinations were generated by ‘Design-Expert software (9.0)’ (Statease Inc., Minncapolis, MN, USA) using the design matrix and variable combinations in experimental runs as presented in Table 2. Each sample combination was prepared in food laboratory of Department of Food Science and Nutrition, Banasthali University. Values for response variables fat and fiber were obtained through laboratory analysis. Carbohydrate content was calculated using Nutritive Value of Indian Foods.48 Based upon the liking for each combination, semi trained panel members were asked to give score between 1 to 100 for the overall acceptability. These values were entered into the software data sheet. Experiments were performed in random order.

|

Name |

Units |

-1 level |

+1 level |

- alpha |

+ alpha |

A |

Trigonella foenum-graecum |

g |

3.0 |

8.0 |

1.29552 |

9.70448 |

B |

Soaking time |

hours |

10.0 |

12.0 |

6.63641 |

13.36360 |

C |

Gymnema sylvestre |

g |

3.0 |

5.0 |

2.31821 |

5.68179 |

Table 1 Levels of process factors to optimize vegetable cereal mix

|

Generated |

Estimated |

|||||

S. No. |

Trigonella foenum-graecum (g) |

Soaking time (hrs) |

Gymnema sylvestre (g) |

Fat (g) |

Fiber (g) |

Carbohydrate (g) |

Overall acceptability |

1 |

3.00 |

8.00 |

5.00 |

1.00 |

1.60 |

30.31 |

85.60 |

2 |

8.00 |

8.00 |

3.00 |

1.20 |

2.00 |

27.84 |

86.70 |

3 |

5.50 |

10.00 |

5.68 |

0.21 |

2.60 |

29.72 |

86.60 |

4 |

3.00 |

12.00 |

5.00 |

0.24 |

1.60 |

29.58 |

86.00 |

5 |

5.50 |

10.00 |

4.00 |

0.14 |

2.00 |

28.48 |

87.30 |

6 |

5.50 |

10.00 |

4.00 |

0.14 |

2.00 |

28.48 |

89.10 |

7 |

5.50 |

10.00 |

4.00 |

0.14 |

2.00 |

28.48 |

87.30 |

8 |

3.00 |

8.00 |

3.00 |

1.80 |

1.60 |

27.39 |

88.20 |

9 |

5.50 |

10.00 |

4.00 |

0.14 |

2.00 |

28.48 |

87.80 |

10 |

5.50 |

6.64 |

4.00 |

0.14 |

2.00 |

28.48 |

87.10 |

11 |

5.50 |

10.00 |

4.00 |

0.14 |

2.00 |

28.48 |

89.00 |

12 |

8.00 |

12.00 |

3.00 |

0.40 |

1.00 |

27.84 |

88.00 |

13 |

8.00 |

10.00 |

4.00 |

0.50 |

2.00 |

29.05 |

88.60 |

14 |

9.70 |

12.00 |

3.00 |

1.00 |

1.64 |

27.39 |

88.60 |

15 |

3.00 |

10.00 |

5.00 |

0.14 |

2.00 |

28.48 |

88.80 |

16 |

5.50 |

8.00 |

5.00 |

1.00 |

3.00 |

29.81 |

89.60 |

17 |

8.00 |

12.00 |

5.00 |

1.20 |

3.00 |

29.91 |

86.70 |

18 |

1.30 |

10.00 |

4.00 |

0.10 |

1.80 |

27.81 |

88.80 |

19 |

5.50 |

10.00 |

2.32 |

0.05 |

1.60 |

26.77 |

88.73 |

20 |

5.50 |

13.00 |

4.00 |

0.50 |

1.60 |

28.48 |

86.86 |

Table 2 Experimental runs and actual values of factors/ responses used in central composite rotable design

Data analysis and optimization

The data collected from the experiments conducted on the various combinations were then subjected to a second order polynomial regression analysis using least square regression method to observe the significant effect (p<0.05) of the three independent variables on the four response variables. The behavior of the system can be described by the following second order polynomial equation:

---------- (eq 1)

where Y is the predicted response, βo is the interception coefficients, βi is the linear term, βii is the quadratic term, βij is the interaction term and xi and xj represent the coded levels of independent variables. ANOVA of the regression equation allowed the calculation of goodness of fit and the significance of the linear, quadratic and interaction effects. The independent variables for ANOVA were Trigonella foenum-graecum, soaking time (hours) and Gymnema sylvestre while dependent variables were fat, fiber, carbohydrate and overall acceptability. The validity of the models obtained was evaluated as a function of their respective coefficients of determination (R2) as well as by an analysis of the lack of fit. A good model must be significant and lack of fit must be insignificant. The predicted R2 value should be in reasonable agreement with adjusted R2.49 R2 can be defined as the ratio of explained variation which was measure of the degree of fit.50 The coefficient of variation (CV) describes the extent to which the data are dispersed.38 The response surfaces and contour plots were generated for different interactions of any two independent variables while holding the value of third variable at the midpoint. These contour plots could provide accurate geometrical representation and provide accurate useful information about the behavior of the system within the experimental design.

The optimization of the process was aimed at finding the levels of independent variables that would give the fat, fiber, carbohydrate and overall acceptability in accordance to the goals set. Numerical optimization technique of the Design-Expert software (9.0) (Statease Inc., Minncapolis, MN, USA) was used for simultaneous optimization of the multiple responses. The desired goals for each factor and responses were chosen (Table 3). Certain optimal solutions were generated by the software. An optimal solution having highest desirability was selected as the optimized recipe. This optimized recipe was prepared in food laboratory and its sensory, physico-chemical and microbiological analysis were undertaken. Results of sensory and microbial analyses were expressed in mean±SD.

Factors/ responses |

Goal |

Lower limit |

Upper limit |

Lower weight |

Upper weight |

Importance |

Trigonella foenum-graecum (g) |

In range |

3.00 |

8.00 |

1.00 |

1.00 |

3.00 |

Soaking time (hours) |

In range |

8.00 |

12.00 |

1.00 |

1.00 |

3.00 |

Gymnema sylvestre (g) |

In range |

3.00 |

5.00 |

1.00 |

1.00 |

3.00 |

Fat (g) |

Minimize |

0.02 |

1.00 |

1.00 |

1.00 |

3.00 |

Fiber (g) |

Maximize |

1.00 |

3.50 |

1.00 |

1.00 |

3.00 |

Carbohydrate (g) |

In range |

26.77 |

30.31 |

1.00 |

1.00 |

3.00 |

Overall acceptability |

Maximize |

86.00 |

90.00 |

1.00 |

1.00 |

3.00 |

Table 3 Optimization criteria for different process variables and response variables of vegetable cereal mix

Sensory analysis

A 15 member semi trained panel was selected through triangle test to carry out the sensory analysis.51 Overall acceptability of reconstituted vegetable cereal mix assessed by using nine point hedonic test. In this test, the panelists were asked to measure the degree of pleasurable and unpleasurable experience of food product on a nine point hedonic test from “like extremely” to “dislike extremely”. The former carried a score of 9 while latter was scored as 1. Organoleptic characteristics of the reconstituted products were assessed using 5 point composite rating scale. In this test, the panelists were asked to measure the specific characteristics (appearance, color, taste, consistency and after taste) of a recipe which were rated separately. Each of these attributes was rated on 5 point scale with 5 considered as “excellent” and 1 considered as “poor”. Analysis was done at 0 day and 30days of storage. A 100 point scale was used to assess the overall acceptability (as a response variable of process optimization) of developed vegetable cereal mixes. This scale was used to fit the model for overall acceptability in process optimization.

Physico-chemical analysis

Physico-chemical analysis of only the optimized recipe was undertaken. Moisture and ash were estimated by standard AOAC procedures. Semiautomatic instrumentation technique was used for analysis of protein and fat. Protein was estimated using microkjeldal method using Kel Plus (model no. KES06L, manufactured by Pelican, India). Fat was determined by the soxhlet method using Socs Plus (model no. SCS6, manufactured by Pelican, India). Carbohydrate was computed by substraction method. Crude fiber was estimated using acid alkali digestion method.52 Iron was estimated using Wong’s method. Vitamin C and calcium were determined by titrimetric method.53 Energy was calculated using values given in Nutritive value of Indian Foods.48 Glycemic load (GL) of optimized food product was calculated by multiplying the amount of carbohydrate of each food product by its glycemic index value (GI).54

Microbiological Analysis

Total microbial load of the optimized vegetable cereal mix was determined using the standard pour plate method. The samples (1g) were serially diluted in saline solution (0.9%) and appropriate dilutions (1 ml) were poured on to the respective petri plates. Plate count agar (SM091, Himedia Laboratories Pvt. Ltd., Mumbai, India) was used for determination of total plate count.55 MacConkey agar (SM081, Himedia Laboratories Pvt. Ltd., Mumbai, India) and sabouraud dextrose agar (SM063D, Himedia Laboratories Pvt. Ltd., Mumbai, India) were used for determination of coliform count and yeast and mold counts respectively.56,57 Plates were incubated (i) at 30°C for 72hours for total plate count, (ii) at 35°C for 24hours for coliform count and (iii) at 30°C for 3-5days for yeast and mold count. Colonies formed on agar were counted and expressed as CFU/ml. The replicates were made for each sample.

CFU = Colony forming unit

All three microbial analyses were undertaken at 0 day and 30 day storage of vegetable cereal mix.

Optimization of parameters for ANOVA

Fit summary statistics was used to choose a suitable model for a response comparing the models based on p-values. A model is considered significant, if the p value is less than 0.05. ANOVA is an important tool for the evaluation of significance and goodness of fit of regression model and significance of individual model coefficients.58 The results of ANOVA for the effect of process variables on fat content indicated that, there was no p value or F value for the model. Thus, the model had neither significant nor non significant effect on the response, fat. Results of effect of process variables on fiber indicated that, the model [two factor interaction design (2FI)] had a significant effect (p<0.05) on the response, fiber. Results of the effect of process variables on carbohydrate depicted that, the model had significant effect (p<0.05) on the response, carbohydrate. Results of the effect of process variables on overall acceptability illustrated that the model (2FI) had non-significant effect (p>0.05) on this response variable. Lack of fit was non-significant (p>0.05), indicating that model fit the data well.

Optimization of parameters for regression coefficients (R2)

The parameters obtained by fitting of fat, crude fiber, carbohydrate and overall acceptability data are presented in Table 4, along with the regression coefficients of intercept, linear and cross product terms of model. The fitness and adequacy of model were judged by the coefficient of determination. A suitable model is the one with the higher order polynomial where the model is significant. The closer the R2 value to the unity, the better the empirical model fits the actual data. The R2 values were, 0.88, 0.91 and 0.52 for fiber, carbohydrate and overall acceptability respectively, suggesting a fair fit of model. The R2 of a model refers to the proportion of variation in the model rather than random error. The regression model developed could explain 88% of variations in the fiber content, 91% of the variations in the carbohydrate content and 52% of the variations in overall acceptability of vegetable cereal mixes (Table 4). The lower CV values for fiber, carbohydrate and overall acceptability indicated that the results were precise and reliable. Similar results related to regression analysis were observed in study of Gupta et al.,59 and Jain et al.,60

Coefficient |

Fat |

Fiber |

Carbohydrate |

Overall acceptability |

Intercept |

0.490 |

1.950 |

28.560 |

87.770 |

Linear |

|

0.210** |

0.210* |

0.170NS |

Cross product |

|

-0.130NS |

|

-0.300NS |

R2 |

0.000 |

0.880 |

0.910 |

0.520 |

Adjusted R2 |

0.000 |

0.830 |

0.890 |

0.310 |

CV% |

106.590 |

9.950 |

1.060 |

1.070 |

Table 4 Regression coefficients of predicted quadratic polynomial models of vegetable cereal mix

* Significant at 5% level of significance

** Significant at 1% level of significance

NS Non significant at 5% level of significance

Effect of process condition for fat

The observations for fat with different combination of process variables are presented in Table 2. The linear and cross product terms of Trigonella foenum-graecum, soaking time and Gymnema sylvestre did not have any effect on the fat content of the vegetable cereal mix, hence, were removed from the model. In this case, mean value was the better predictor than any model, therefore, mean value of fat 0.48500 was used.

Effect of process conditions for fiber

The observations for fiber with different combination of process variables are presented in Table 2. The regression equation describing the effect of the process variable on fiber in vegetable cereal mix in terms of actual level of variables is given as-

Fiber=5.03764-0.26317 * Trigonella foenum-graecum - 0.15678 * Soaking time - 1.09611 * Gymnema sylvestre - 0.026000 * Trigonella foenum-graecum * Soaking time+ 0.15200 * Trigonella foenum-graecum * Gymnema sylvestre + 0.60000 * Soaking time * Gymnema sylvestre

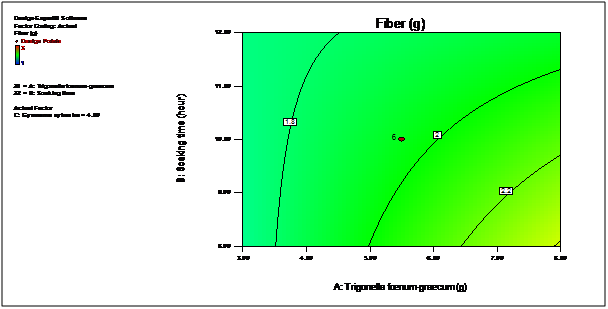

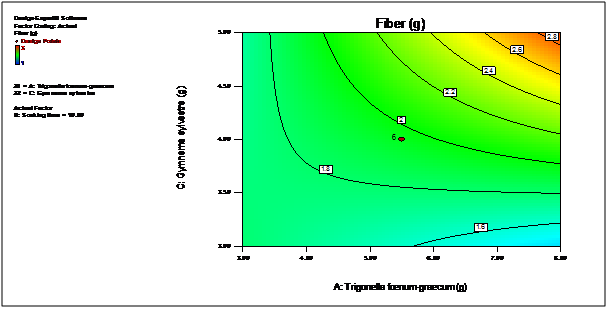

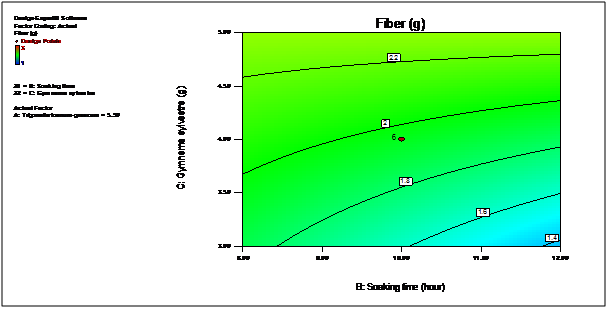

The response surface (Figure 1) developed shows linear curves with Trigonella foenum-graecum and soaking time. It was observed that linear term of Trigonella foenum-graecum (p=0.00) and cross product term of Trigonella foenum-graecum with Gymnema sylvestre (p<0.00) have significant influence on the fiber content of vegetable cereal mixes. In middle of each graph, centre points (6) are shown with red colour. The response plot (Figure 2) indicated that the fiber content of vegetable cereal mixes increased with decreasing amount of Gymnema sylvestre and increasing amount of Trigonella foenum-graecum. Gymnema sylvestre shows significant influence (p<0.00) in linear terms of model whilst it shows no significant influence in its cross product term with soaking time (p=0.10). The response plot (Figure 3) depicted that the fiber content increases with increasing amount of Gymnema sylvestre and soaking time.

Figure 1 Interactive effects of Trigonella foenum-graecum and soaking time on fiber content of vegetable cereal mix.

Figure 2 Interactive effects of Trigonella foenum-graecum and Gymnema sylvestre on fiber content of vegetable cereal mix.

Figure 3 Interactive effects of soaking time and Gymnema sylvestre on fiber content of vegetable cereal mix.

Effect of process condition for carbohydrates

The observations for carbohydrate with different combination of process variables are presented in Table 2. The regression equation describing the effect of the process variable on carbohydrate of instant mix in terms of actual level of variable is given as-

Carbohydrate=24.20701+0.0823065*Trigonella foenum-graecum-0.023065*Soaking time+1.03328 * Gymnema sylvestre

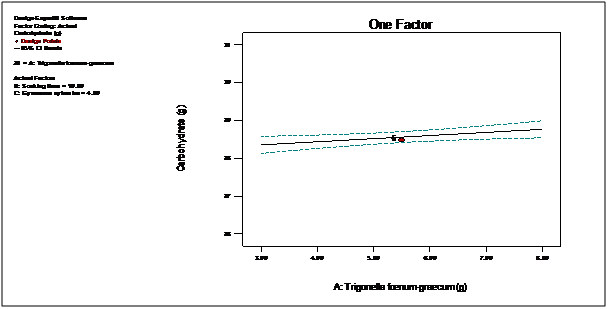

The response plots show linear plots with Trigonella foenum-graecum (Figure 4), with soaking time (Figure 5) and with Gymnema sylvestre (Figure 6). (Figure 4) (Figure 5) does not show any relation of Trigonella foenum-graecum or soaking time with carbohydrate content but ANOVA statistics illustrated that the carbohydrate content of vegetable cereal mixes was increased significantly with increasing amount of Trigonella foenum-graecum (p=0.02) and Gymnema sylvestre (p<0.00). The interactive effect of amount of Trigonella foenum-graecum on response variable, carbohydrate (Figure 4) indicated that, the maximum carbohydrate content (28.5g) was obtained at 8.0g Trigonella foenum-graecum and the minimum carbohydrate content (28.3g) was obtained at 3.0g Trigonella foenum-graecum. The interactive effect of soaking time on response variable, carbohydrate (Figure 5) indicated that, the maximum carbohydrate content (28.6g) and minimum (28.3g) carbohydrate content was obtained at 8.0hours and 12.0hours soaking time respectively. The interactive effect of amount of Gymnema sylvestre on response variable carbohydrate (Figure 6) indicated that, the maximum carbohydrate content (29.3g) was obtained at 5.0g Gymnema sylvestre and minimum carbohydrate content (27.5g) was obtained at 3.0g Gymnema sylvestre.

Figure 4 Interactive effect of Trigonella foenum-graecum on carbohydrate content of vegetable cereal mix.

Effect of process condition for overall acceptability

Sensory attributes play an important role in modification, improvement, development and acceptance of new food products.61 Overall acceptability is an important factor directly related to the likability of any new formulated food product. For evaluating the overall acceptability of reconstituted vegetable cereal mix, the 100 point scale was used. The observations for overall acceptability with different combination of process variables are presented in Table 2. The regression equation describing the effect of the process variable on overall acceptability of instant mix in terms of actual level of variables is given as-

Overall acceptability=83.62914-0.69370*Trigonella foenum-graecum + 1.33593 * Soaking time +0.22909 * Gymnema sylvestre - 0.60000*Trigonella foenum-graecum * Soaking time + 0.3400 * Trigonella foenum-graecum * Gymnema sylvestre

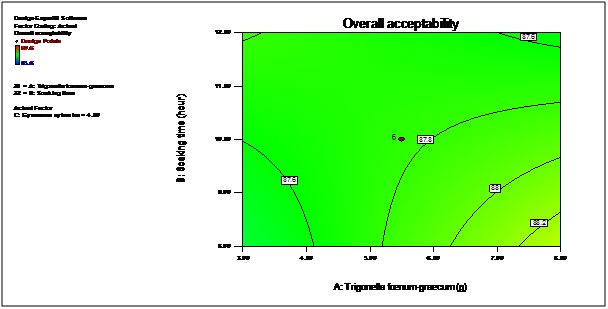

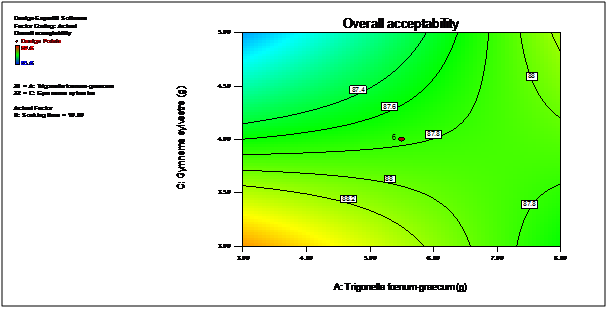

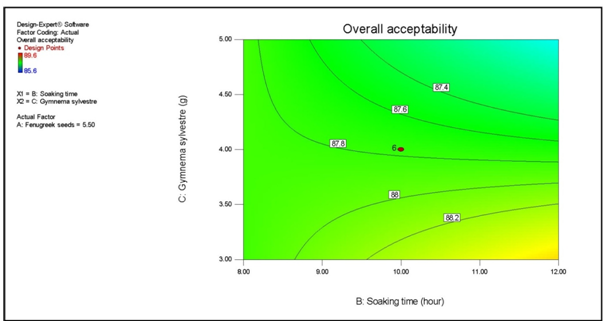

Curvilinear plots were observed with Trigonella foenum-graecum and soaking time (Figure 7); Trigonella foenum-graecum and Gymnema sylvestre (Figure 8); and soaking time and Gymnema sylvestre (Figure 9) for the overall acceptability of vegetable cereal mixes. Only linear term of Gymnema sylvestre (p=0.05) and combination of Trigonella foenum-graecum and Gymnema sylvestre (p=0.02) have significant influence on the overall acceptability of vegetable cereal mixes.

Figure 7 Interactive effects of Trigonella foenum-graecum and soaking time on overall acceptability of vegetable cereal mix.

Figure 8 Interactive effects of Trigonella foenum-graecum and Gymnema sylvestre on overall acceptability of vegetable cereal mix.

Figure 9 Interactive effects of soaking time and Gymnema sylvestre on overall acceptability of vegetable cereal mix.

Optimization of process parameters

On the basis of above described results, it can be asserted that the quality of the vegetable cereal mix is not dependent on a single main factor. All independent variables were important in defining the characteristics of the vegetable cereal mix. Hence, the next step involved the detection of the best combination of process/independent variables that are able to produce the expected characteristics of final product. Therefore, numerical optimization was carried out for the process parameters for obtaining the best product from vegetable cereal mix. The Design Expert (9.0) software was used for simultaneous optimization of the multiple responses. The desired goals for each factor and response were chosen (Table 3). The software generated 47 solutions of independent variables with the predicted values of responses. Desirability of optimum solutions ranged between 0.62-0.87. Their optimum solutions were obtained on the basis of highest desirability. These optimum recipes had (i) 8.0g Trigonella foenum-graecum, 8.0hours soaking time and 5.0g Gymnema sylvestre with 0.48g fat, 3.01g crude fiber, 29.84g carbohydrate and overall acceptability score of 89.17; (ii) 8.0g Trigonella foenum-graecum, 8.0hours soaking time and 4.99g Gymnema sylvestre with 0.48g fat, 3.01g crude fiber, 29.84g carbohydrate and 89.16 score for overall acceptability; (iii) 8.0g Trigonella foenum-graecum, 8.01hours soaking time, 5.0g Gymnema sylvestre with 0.48g fat, 3.01g fiber, 29.84g carbohydrate and 89.16 score for overall acceptability in 53g of products. These optimum solutions provided the range of process variables which could be considered as the optimum range for best product quality in terms of fat, fiber, carbohydrate and overall acceptability. These were appropriate conditions to produce vegetable cereal mix with nutritional benefits without compromised on sensory attributes. Once the best solution had been pinpointed among these optimum solutions, it was used to formulate the optimized/enhanced vegetable cereal mix. Solution 1, having the maximum desirability value 0.87 in a range of 0.62 to 0.87, along with minimum fat content, maximum fiber and maximum overall acceptability was selected for further laboratory analysis. Fat ranged between 0.05 to 1.8 g which is also reflected by high CV% value (Table 4). But optimum recipe contained low fat that was chosen by high desirability. Thus, the set goal (minimum fat content) was met.

Incorporation of Trigonella foenum-graecum and Gymnema sylvestre significantly increased the fiber content in vegetable cereal mix. Trigonella foenum-graecum constitutes 50% of unavailable carbohydrates making this the highest concentration among all the natural sources of fiber. Trigonella foenum-graecum was the main contributor to high fiber content and it adds both insoluble and soluble dietary fiber, particularly soluble fiber ‘galactomann’.62 This is the factor responsible for antidiabetic activity of Trigonella foenum-graecum.63 Similar finding of increased fiber content of biscuits incorporating Trigonella foenum-graecum and flax seed was reported by Metwal et al.64 In this study, carbohydrate content of vegetable cereal mix had high carbohydrate owing to its high fiber content. Addition of Trigonella foenum-graecum had no significant effect on overall acceptability of developed vegetable cereal mix which was incorporated in the range of 5.5-8.0 g in the recipes marked as highly acceptable by the panelists. In reconstituted vegetable cereal mix the characteristic bitterness of Trigonella foenum-graecum seeds reduced because seeds were soaked and washed before preparation and therefore, the palatability of the mix was not compromised. Jain et al.,44 conducted a study on optimization of upma mix incorporating Trigonella foenum-graecum using RSM. Results indicated that optimum recipe obtained 8.7 score rated on a 9 point hedonic scale. This recipe was high in fiber and had good sensory characteristics.

Sensory analysis

The organoleptic properties of reconstituted optimized instant vegetable cereal mix were evaluated using 5 point composite rating scale. Mean score for all sensory attributes were above 4 (suggesting ‘very good’) at zero day of storage. The mean scores for appearance, colour, taste, consistency and after taste were 4.7±0.45, 4.7±0.47, 4.4±0.51, 4.6±0.48 and 4.6±0.50 respectively. Results revealed that sensory attributes of product were not affected by storage as similar mean organoleptic scores were obtained at 30 days of storage. Vegetable cereal mix was stored in auto seal sachet at room temperature. The mean scores for appearance, colour, taste, consistency and after taste of optimum recipe (at 30th day of storage) were 4.8±0.41, 4.8±0.41, 4.4±0.50, 4.4±0.51 and 4.4±0.50 respectively. Overall acceptability of optimum product was assessed using 9 point hedonic scale. Results showed that vegetable cereal mix obtained similar mean hedonic score at zero day (8.5±0.51) and at 30th day of storage (8.4±0.50). No significant difference (p>0.05) was observed in various sensory parameters of vegetable cereal mix. Prabha et al.,65 formulated biscuits and bread by incorporating Gymnema sylvestre powder added hypoglycemic mix at 1%, 2% and 3% levels. Results illustrated that products had significantly higher acceptability at 1% incorporation level than 2% and 3%. Ibrahim and Hegzay9 developed biscuits incorporating soaked and germinated Trigonella foenum-graecum at different levels. Biscuits with 5% Trigonella foenum-graecum incorporation were highly acceptable in terms of all sensory characteristics. These results were in accordance with present investigation. Similar results were found in studies of Goel et al.,66 Hooda and Jood67 and Rahnama et al.,68

Physico-Chemical analysis

The physico-chemical properties of the optimum recipe were assessed to evaluate the food nutritionally. The nutrients were estimated per 100g quantity. The optimized recipe was found to be nutritionally adequate. Optimum recipe had 332.3kcal energy (calculated), 2.62g moisture, 0.71g ash, 20.99 g protein, 2.61g fat, 3.77g crude fiber, 129.05mg calcium, 4.05mg iron and 0.80mg vitamin C. Its glycemic load was 14.7g/100g. In study, blends of wheat and Trigonella foenum-graecum flour were used to develop bread, biscuit, noodles and macroni at different levels (10%, 15% and 20%). Incorporation of Trigonella foenum-graecum significantly increased the total protein, lysine, minerals and dietary fiber contents of biscuits.69 Mahmoud et al.,70 conducted a study on nutritional analysis of wheat biscuits supplements incorporating Trigonella foenum-graecum. The germinated Trigonella foenum-graecum seed powder was incorporated at 5 to 10% levels. Results revealed that Trigonella foenum-graecum flour was good source of protein, fat, fiber and minerals as was also observed in our study. Vegetable cereal mix had high protein content which had been contributed by defatted soy flour. Kumar et al.,71 reported that protein content of soy flour added multigrain premixes had similar protein content as found in present study.

Microbiological analysis

The presence of total microbial load in this product is the net result of microbial contamination of the raw materials, handling and the type of sanitary control exercised during the production, processing, transportation and storage. In this investigation, care was taken to maintain environmental and personal hygiene to reduce the contamination during the preparation and storage of vegetable cereal mix. Results of total plate count indicated that the mean count of vegetable cereal mix were 3750.0±353.55 at zero day and 6000.0±707.10 at 30th day of storage. Shelf life analysis revealed no significant difference (p=0.07) in total plate count. Presence of microorganisms was in acceptable range according to the Indian standards.72 The mean coliform count was 15.0±7.07 at zero day and 40.0±14.14 at 30th day of storage. No significant difference (p=0.12) was observed in coliform count with increase in duration of storage. The mean yeast and mould count was 265.0±35.35 at 30th day of storage. A significant (p=0.04) reduction in yeast and mould count was observed during storage. This reduction can be attributed to presence of the antifungal substances in the vegetable cereal mix. Similar results of total plate count and coliform count were observed in study of Randhawa et al.,73 Microbial load was higher in samples stored at 30days than 0 day. The shelf life of the product was one month beyond which it was not studied. These results are in accordance with the observations of Bharathi and Sindhu74 in which they developed antioxidant rich instant biscuit mix. Wijewardana et al.,75 also depicted that total plate count increased at 30day storage of ready to bake vegetarian cake mix 1. Contradictory results were found in the study of Mogra and Choudhry76 in which microbial load decreased during the storage of rab mixes.

RSM was successfully used to pinpoint the best combination of different factors (amount of Trigonella foenum-graecum, soaking time of Trigonella foenum-graecum and amount of Gymnema sylvestre) for development of vegetable cereal mix. Out of 47 suggested formulations, 3 formulations had highest desirability index (0.87) compared to all other formulations. Recipe having 8.0g Trigonella foenum-graecum, 8.0hours soaking time and 5.0g Gymnema sylvestre with 0.48g fat, 3.01g crude fiber, 29.84g carbohydrate and 89.17 score for overall acceptability was further subjected to nutritional and microbial analysis. Optimum recipe had minimum fat, maximum fiber content along with high acceptability. It was rich in protein and calcium. Optimum recipe had desirable sensory characteristics and its storage quality was appropriate uptil 30days. Vegetable cereal mix is convenient to use, health promoting and cost effective, hence it can be easily used by the consumers as food add-on without altering their usual diet.

None.

Author declares that there is no conflict of interest.

©2016 Gupta, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.