Journal of

eISSN: 2373-4310

Research Article Volume 8 Issue 1

1Department of fisheries and Aquaculture, Federal university, Nigeria

2Department of Home Science and Management, Federal university, Nigeria

Correspondence: Ogori AF, Department of fisheries and Aquaculture, Federal university, Gashua PMB1005, Yobe State, Nigeria

Received: July 28, 2017 | Published: January 9, 2018

Citation: Idi OAM, Ogori AF, Omoniyi SA. Design and fabrication of pneumatic charcoal kiln drying characteristics and residence temperature for cat fish smoking. J Nutr Health Food Eng. 2018;8(1):9-12. DOI: 10.15406/jnhfe.2018.08.00250

The fabrication of pneumatics charcoal kiln for fish smoking was done with the objective of replacing the existing open kiln smoking of fish. The pneumatic kiln of rectangular metal plate made from wrought iron of 2mm thickness has three chambers: The fan chamber, powered by a solar energy, charcoal chamber and the smoke chambers respectively. The chambers were insulated with 20mm thick thermosetting polymer which is welded in between two wrought irons. At the end of the smoke chambers is connected a pneumatic pump pipe that further assists in heat connective flow mechanism during operation. The kiln is operated automated by switching in the fan set button. The machine performance was evaluated using cat fish, smoked to an average moisture content of 47.1% within an average time span of 1h, and the average final weight of the dried fish was 1.03Kg. It was projected that increasing time for drying from 2-3hours and maintaining residence temperature of 60-83°C, pneumatic charcoal kiln could become best potential fish kiln that can keep fish longer without further spoilage.

Keywords: cat fish, pneumatics kiln, moisture content, temperature, smoke charcoal, chambers

Drying is one of the essential unit operations performed to increase the shelf life of agricultural or horticultural produce and it is one of the most practical methods of preserving food and the quality of agricultural produce.1 Traditionally, fish food produce are dried by spreading in open sun in thin layer and smoking using wood. Though this method is economical and simple, it has the draw backs like; no control over the rate of drying, non-uniform drying, chances of deterioration due to exposure of products against rain, dust, storm, birds, rodents, insects and pests which results in poor quality of dried products . Whereas, kiln pneumatic drying system leads to fast rate of smoke- drying and exposure of products against rain, dust, storm, birds, rodents, insects and pests may obviously be avoided. Against this, open sun drying and smoke processing drying requires longer drying time and product quality are however difficult to control because of inadequate drying, high moisture, fungal growth and encroachment of insects, birds and rodents, as well as economy of space.1 Drying is usually conducted by vaporizing water in the product Fellow 1988.Thus; the latent heat of vaporization must be supplied. Airflow is also required to remove the vapor away from the product. The lower the humidity of hot air supplied to the drying chamber, the better the drying rate, as the less humid air can carry more moisture from the product surface than the more humid air. Generally, increasing the temperature and velocity shortens the drying time hence pneumatic processing. For heat-sensitive products, such as fish food and pharmaceutical products, high temperature decreases product quality. In this case, drying at low temperature and humidity is required to maintain the fresh color of the product using the desiccant system.1

Dried fish production in one country does not vary much from another.2 In most cases, fish drying (cat fishes) process in the rural areas is done in the same manner as the old practice fifty years ago.2 A break through to quality and economic catfish smoke- drying production methods is very limited. In many state, all over the country, catfish is sold to the market in poor quality condition. Usually percentage of spoilage is high because required moisture content and the water activity in the product after drying completion is above the desired requirement with attendant mold growth and bacteria.2 Un-dried fish are easy target of insects and bacteria which result to foul smell, decay and deterioration. Double handling of fish product is rampant.3

Maximum drying rates are desired though product quality must be considered. During drying, some tissue have a tendency to form dry surface layers which are impervious to subsequent moisture transfer if the drying rate is very rapid. To avoid this requires effective control of the drying process. The heat transfer and evaporation rates must be closely controlled to guarantee optimum drying rates. The control of the drying process in natural-circulation dryers presents a major problem,4 as such dryers are made to minimize capital and running costs. The best approach is to incorporate into the design of the dryers such structural features that would guarantee that extreme conditions not to prevail in the dryer under the envisaged climatic conditions and crop properties.4

Drying characteristic of product is one of the many important factors that provide criteria in the selection and aspects in the choice of design and method of operation of drying plants. Most of the fish harvested in the tropics is used for direct consumption but a great deal is processed into fish meal for use in compounding feeds.5 But a great deal is processed into fish meal for use in compounding feeds.5 Also according to Eyo, a significant quantity is lost as a result of the absence of adequate technology to prevent spoilage.

Design calculation

Volume of the kiln: kiln capacity is related to the volume Volume of pneumatic kiln smoking chamber

Where

L= length of the smoking chamber=0.609m

B= width of smoking chamber=0.914m

H= Height of smoking chamber=0.609m

VP= 0.609×0.914×0.609=0.338m----------- (1)

= 338cm3

Volume of charcoal chamber

Where

L=length of charcoal chamber=0.457m

b= width of charcoal chamber=0.305m

h= height of charcoal chamber=0.457m

Vc= 0.457X 0.305X 0.457 ------------- (2)

=0.0636m or 63.6 cm3

Diameter of fan blower at a fixed position

Moment=f×length or (height) --------- (3)

Where

f=50 watt

L=0.305m

=50×0.305=15.25Nm

Velocity of air into the product Chamber from fan blower

------------ (4)

Where

d= distance from fan position to end of smoking chamber=0.1525m×0.305m×0.914m

= 0.0426m3

T=time in second

But ------------------------------- (5)

FT=1

But T=1/F where F= 50 Hz. Given

Therefore Va=0.0428m÷0.02=0.042 ÷ 0.02=2.13m/s.

Heat transfer by conduction is obtained as:

-------------------------------------------- (6)

Where

Thermal conductivity K= 59wm/k

A=area of the fish tray =l x b=0.609×0.914=0.556m2

L= distance between the smoking chamber and the charcoal chamber=2m.

T1=temperature of the inside smoking chamber =38.9 0C (assumed)

T2=temperature of the outside =36. 8 0C (assumed)

q= 59×0.609×0.914 (38.9- 36.8)

2

q=34.48J/m2

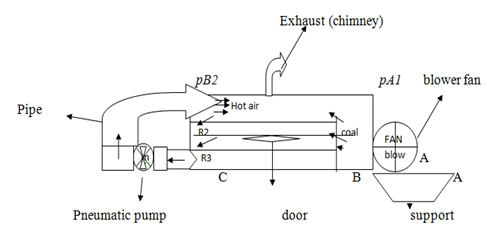

Chaka plate (wrought iron) metal sheet of 2mm was used for construction of all the chambers. The fan chamber, charcoal chamber and the smoking chamber. The charcoal and the smoking chambers were insulated with a thermosetting polymer of 100mm thickness. These were welded to a fit tight position. The fan chamber has 0.457m×0.305m×0.457m as the length, width and height respectively. The charcoal chamber has 0.457m×0.305m×0.457 as the length, width and height respectively. The smoking chamber has 0.609m×0.914m×0.609m as the length, width and height dimensions (Figure 1).

Figure 1 Design of Pneumatic Charcoal Kiln Drying.

Keys: R, racks; pA1, positional one of kiln chambers; pB2, positional two of kiln chambers; A, fan chamber; B, charcoal chamber; C, smoking chamber

The pneumatic pump fitted at the other width base would be adjusted to allow recycling of warm air back into the kiln chamber. At the junction of inlet pneumatic pipe, chimney outlet and hot air inlet interphase, less dense air mass would escape, such as fish methane and propyl compounds (Figure 1). Pneumatic charcoal kiln was design and fabricated with the aim of fulfilling the following objectives: safety in quality and economy of labour, efficiency in performance

The motor/fan

These are fixed on the width of the fan chamber connected to a solar panel with a regulator attached to control the blade speed.

The fish trays

It is a container meshed in a rectangular form of 0.0609m ×0.914m length and width dimension. Each fixed at a distance of 0.122m from each other, in the smoking chamber. R1 and R2.

The pneumatic system

Is a pipe connected from the center of the chamber up length to the width center with a pneumatic pump of 25psi. This is welded to circulate heated air within the chamber through the connected pipe

Pneumatic charcoal kiln assembly

The fan chamber, charcoal chamber, smoking chamber and the pneumatic pump were welded together making a complete pneumatic kiln Figure 1 depicts.

Operation of the pneumatic charcoal kiln

The cat fish to be smoked were washed; weighted and placed on the wire gauge meshed trays and charged into the smoking chamber. The charcoal is lit, the burning charcoal supplies heat which dries the fish. The fan is regulated and blows air through the charcoal chamber into the smoking chamber through a meshed opening or aperture of 8x 8m. The ash drops at the base from the charcoal chamber after each process by sliding out a metal cover.

Performance evaluation

Cat fish were obtained from Gashua fish market. The samples were thoroughly washed, drained, weighed and charged into each tray. The charcoal on the charcoal chamber was first ignited using kerosene and allowed to burn for 6-10minute, this allow odour of kerosene to go up and then charcoal added. The tray one has about 1.5kg. Tray 2 also has 1.5kg of fish. The fan was set in motion of speed one and timed. During the smoking process, the help of the pneumatic system and the closure of the smoking chamber allows for convective heat flow which disallow turning the fishes side to side or upside down. The smoking process was allowed after 60min on temperature of the chamber after every 30min and the temperature of the chamber taken to ascertain resident temperature of the smoking chamber at the two ends of the smoking chamber, PA1/PB2 respectively (Figure 1).

The moisture content of 47.1% calculated from equation (6) is above the 10-15%

Safety moisture content of dried fish according to Ikenweiwe et al.6 After the 60min smoking process the fish is allowed to cool in a plastic container.

------------- (7)

Where,

Mc db=moisture content by dry basis in percentage

Initial weight=weight of drained fish in kg

Final weight=weight of smoked fish after 60min in kg

The design and fabricated pneumatic charcoal kiln smoking machine was rigid and operate perfectly with no manual effort to operation. The pneumatic kiln was tested with fresh cat fish of 1.5kg on each tray (Table 1).

|

Tray no |

Initial weight(W1) Kg |

Time taken (Min) |

Final weight (W2) Kg |

% Mc |

|

1 |

1.5 |

60 |

1.1 |

36.3 |

|

2 |

1.5 |

60 |

0.95 |

57.9 |

|

Min |

1.5 |

60 |

1.025 |

47.1 |

Table 1 Drying Performance

Table 1 shows that the short time given (1hr), the moisture contents were averagely low, though not to a safe level.6,7 By projection 4-5hours smoking will reduce the moisture contents to a safety level of between (8-9%) taking into consideration the weight/size of the fish, initial moisture content, fat content, and heat dynamics in the smoking chamber as well as intensity of heat supplied7 (Table 2).

|

Tray no |

Time (Min) |

(PA1) to T2 (°C) |

(PB2) toT2 (°C) |

|

1 |

60 |

(85.8) 302, 116 |

(63.8) 30.2, 94 |

|

2 |

60 |

(81.5) 30.1, 111.6 |

(56.9) 30.1, 87.1 |

|

Mean |

60 |

83.6 |

60.4 |

Table 2 Resident temperature

This machine is found to be potentially useful above the local method of smoking fish that normally spans through 24hours in addition to intensive labour and heat skin laison effects. The residence temperature of 83.6°C and 60.4°C in the smoke chamber may increases drying rate by recycling drying process (Table 2).

Pneumatic charcoal smoking kiln that is easy to operate, requiring no energy cost, potable and easy to maintain was design and fabricated. The pneumatic kiln was tested using cat fish. The kiln efficiency is predictable within an hour of smoking process. This machine could be used for drying and re-drying of fish and other soft tissue of animal and plant food sources.

The authors acknowledged the grant received from The Tertiary Education Trust Fund (TetFund) through the Federal University, Gashua, Nigeria that made it possible to carry out this research work.

The author declares no conflict of interest.

©2018 Idi, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.